How to Prepare for a Tight Capacity Market: 4 Steps Shippers Can Take

How can you recognize a tight truckload capacity market?

The balance of carrier supply and shipper demand is always shifting in the fragmented and dynamic truckload market, which means that truckload rates move with it.

As a tighter capacity environment approaches (AKA a “carriers’ market”), you’ll start noticing a few things:

- Carriers stop calling to ask for freight.

- Your primary tender acceptance starts to dip.

- Your truckload spot rates start creeping up.

When you see any — or especially all — of these three things, you’ll know we’re heading back into an inflationary market.

Whether you ship a few truckloads a month or manage a multi-million-dollar freight budget, there are some steps you can take now to prepare for a tight truckload market.

Learn these four tips for shipping smarter when capacity gets tight and keep your supply chain moving.

Related: Learn more about truckload market dynamics or a breakdown of a how a truckload market cycle operates.

1. Explore Mode Conversion Opportunities

As the truckload market heads toward year-over-year rate inflation, carrier capacity will begin to tighten up relative to demand. This means fewer trucks on the mode to haul all the freight shippers want to move — and it will start driving spot rates up.

As spot rates rise, tender acceptance will likely fall as carriers look to more profitable opportunities in the spot market.

Anything that limits your business’s exposure to the truckload market in these conditions will probably be a net gain. Converting some of your truckload freight to other modes is a great way to diversify your risk, add capacity and protect your freight budget.

6 Reasons to Consider Mode Conversions:

- Adds new sources of capacity.

- Diversifies risk of service disruption.

- Mitigates cost volatility.

- Reduces spend.

- Improves network efficiency.

- Could help minimize carbon footprint.

There are a few different options you can look for in your network. Let’s go over the basics of each.

Full Truckload to Intermodal

Converting your truckload freight to the rail is the first and most obvious option.

There are no hard-and-fast rules to determine which lanes are good candidates for conversion, but there are some basic guidelines.

If the lane currently ships in a 53’ dry van, is at least 700 miles in length and has origin and destination points that are within ~100 miles of intermodal rail facilities (which are in almost every metro area), it’s worth getting an intermodal rate.

When comparing intermodal rates to your current truckload rates, keep in mind that truckload pricing can change quickly in a matter of months or weeks as inflation ramps up and the market tightens. Model in 10%-20% rate increases to give yourself a rough idea of how the two modes will stack up.

Truckload rates may or may not spike that high, but it will at least give you an idea of what is possible and help you put a strategy in place.

If you identify lanes that can convert to the rail, it’s important to understand the key differences between the two modes such as transit expectations, blocking and bracing, and accessorial norms.

Knowing the basics will help you avoid operational hiccups — learn the 4 things every shipper should know about converting TL freight to intermodal.

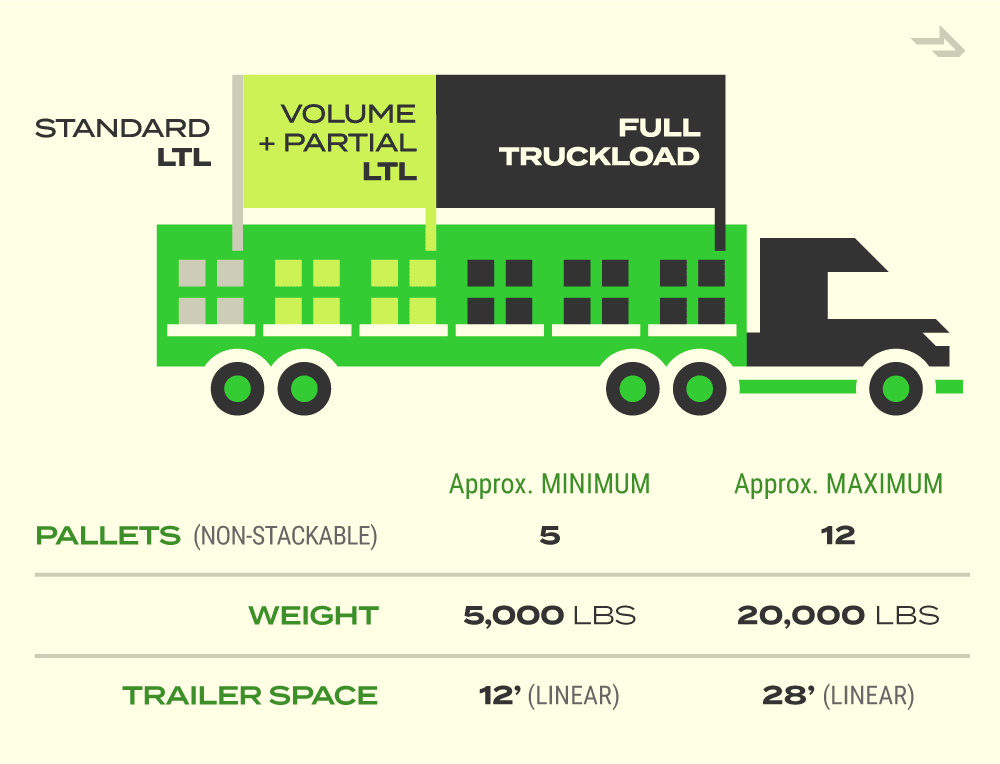

Full Truckload to Volume LTL

These opportunities are not as common as intermodal conversions, but anything that minimizes your exposure to an inflationary spot truckload market will likely be a benefit to your budget.

Volume LTL is essentially a backhaul service from LTL carriers. If you have any truckload shipments that are between five and 12 pallets, volume LTL could be a great cost-saving option.

2. Implement ‘Shipper of Choice’ Strategies Now

You should always strive to be a “shipper of choice” — regardless of market conditions — but it is especially important during the transition from a shipper’s market to a carrier’s market.

As more freight options open up for carriers, these best practices make a difference in securing the capacity you need.

7 Best Practices for Shippers of Choice:

- Have a fair accessorial schedule.

- Pay fast.

- Tender with ample lead time.

- Simplify your appointment scheduling process.

- Have realistic transit times.

- Load & unload drivers as quickly as possible.

- Provide basic amenities to drivers.

Though these are not all possible for every shipper, it’s still important to look at your own supply chain and find areas where you can make improvements.

Becoming a preferred shipper is not an overnight process, but the sooner you start implementing positive change, the better position you’ll be in relative to your competition.

Let’s go a little deeper into each best practice.

Have a Fair Accessorial Schedule

Make sure it is in line with industry standards. Leverage relationships with your carriers, 3PLs and other shippers to see how you compare.

Pay Fast

As the saying goes, in business cash is king — that’s especially true for carriers, in particular smaller ones. Favorable payment terms can make a huge difference for a five-truck operation. Anything under 30 days is ideal.

Tender With Ample Lead Time

This is not always possible, but the sooner you can get a load tender to your carrier, the better they will be able to plan. 48 hours or more is ideal.

Simplify Your Appointment Scheduling Process

Put yourself in your providers’ shoes. What is it like to get an appointment set? Is it a huge operational lift, or is it quick and easy?

Have Realistic Transit Times

Whenever possible, schedule pick-ups and deliveries that make carriers want to haul your freight.

- If transit is too tight and a late driver will have to wait several hours for the facility to work him or her in, the load is not attractive.

- If the pick-up and delivery are too far apart, and a driver will have to sit around to get unloaded, the load is not attractive.

- As a rule of thumb, carriers prefer earlier or a.m. delivery times and a bit later or afternoon pick-up/loading times.

Turn Drivers as Quickly as Possible

The industry standard is two hours or less — anything over that, and your facility is at risk of developing a negative reputation among drivers.

Depending on your freight and operations this may not be possible, but it’s always important to keep in mind.

Allowing for drop trailers when it works for you and the carrier is a great way to improve efficiency.

Provide Basic Amenities to Drivers

Unfortunately, these common sense things are not always common. Access to bathrooms, vending machines, waiting rooms, wi-fi and a friendly smile at the dock go a long way.

3. Measure Carrier Performance

Whether you just awarded hundreds of lanes in an annual RFP event or you’re a small shipper looking to get the perfect spot spot truckload rate, it is important to have a data-driven supply chain — tracking carrier performance is a key part of that.

Make sure you can at least track primary tender acceptance and on-time performance these are essential supply chain key performance indicators (KPIs) for carrier management.

If you can’t track it, how can you make improvements?

Communicate your KPIs to every carrier you work with — they should be crystal clear on your expectations. Regularly evaluate your carrier base. Give them report cards — their performance should not be a mystery to you or them.

You should also have a process in place for taking action for poor performance when warranted.

Again, clearly communicate that process with your providers and make sure you stick to it. Inflationary markets will show you which providers are serious about maintaining a strong relationship with your business.

4. Set Durable Contract Rates

Not all shippers have the ability to secure committed, primary rates in a procurement event, but if you do, make sure to account for both the current and near-future state of the market capacity cycle.

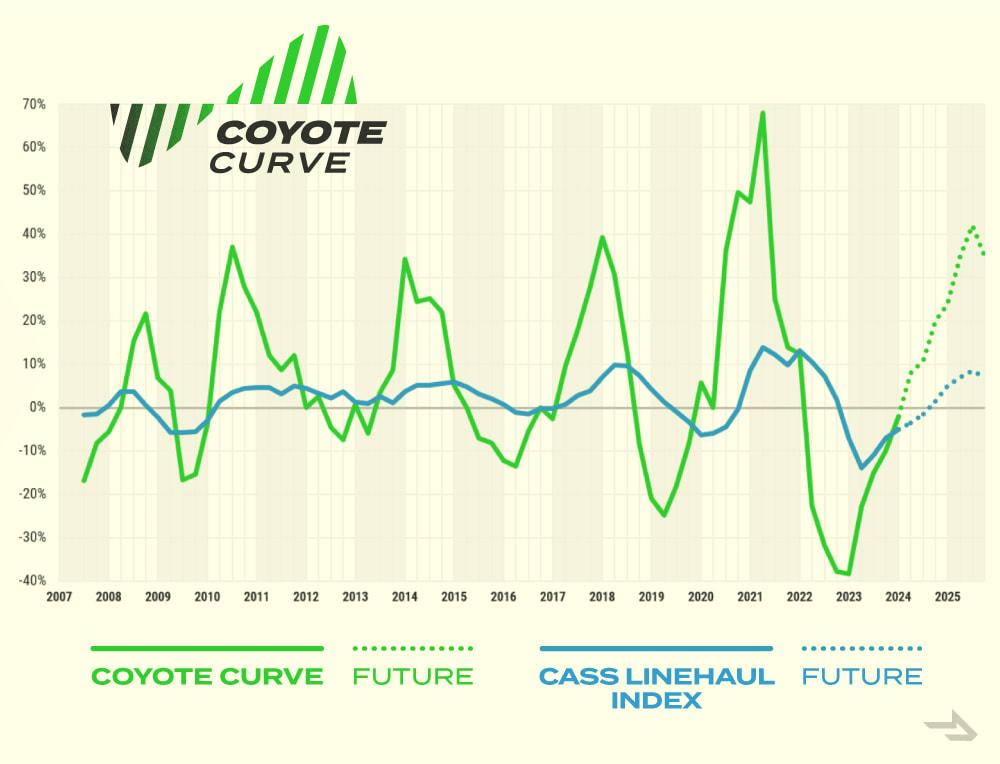

Though spot rates may be rising, contract rates — which take about two to three quarters to respond to spot rate activity — could still be deflating.

As these two indexes cross, it will create market turmoil.

If you are pushing for another round of deep rate reductions in your next bid, those rates may not hold up later in the year as carriers move capacity into the lucrative spot market.

You should anticipate more exposure to the spot market if your rates are unrealistic.

It’s Not Too Late!

If you think some of these tips could better prepare your supply chain for an inflationary market, it’s not too late to act.

Any improvements you make now will help you ship better later. The faster you act, the more likely you will beat your competition to the punch.

4 things you can do to prepare for a tighter truckload market:

- Explore mode conversion opportunities.

- Implement “shipper of choice” strategies now.

- Measure carrier performance.

- Set durable contract rates.

Are We in an Inflationary Market Now?

Find out with our latest truckload market forecast, featuring the Coyote Curve® spot rate index.