The Art & Science of Supply Chain KPIs: Measuring Logistics Success

Setting your transportation strategy is one thing — measuring its effectiveness is another.

But tracking your performance is not always easy.

If you struggle with this, you’re not alone: according to our supply chain KPI research study, most shippers find that turning data into insights is difficult.

But I have good news: You can start getting more out of your supply chain data by setting and tracking key performance indicators (KPIs).

If you want to learn more about supply chain KPIs, you’ve come to the right place.

Below is everything you need to build a more data-driven supply chain.

Complete Guide to Supply Chain KPIs

What Are Supply Chain KPIs?

Supply chain or logistics KPIs (key performance indicators) are metrics that businesses use to assess performance in their shipping network, evaluate freight providers, and identify potential areas for improvement.

Think about supply chain KPIs as a “health check” for your logistics network.

Remember the last time you went to the doctor — you probably had your blood pressure taken, right?

Your blood pressure reading itself doesn’t describe your overall health, but if it’s too high or too low, it triggers further investigation and can lead to lifestyle and/or medication changes.

Supply chain KPIs work the same way.

If your freight providers fail to meet your benchmarks, it doesn’t necessarily mean they need to be fired, but it is a red flag that you need to dive deeper to find out what’s going on before you start losing customers.

What Are the Most Common KPIs in Logistics?

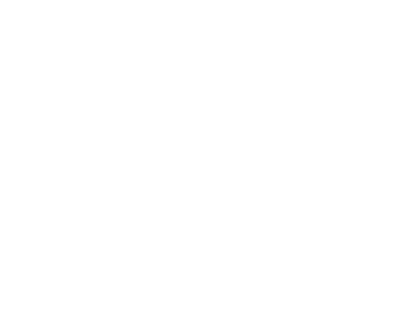

The most common logistics KPIs are:

- On-time delivery

- Cost per shipment

- Appointment scheduling compliance

- Freight tracking compliance

- On-time pick-up

- Cost per pallet

- Sustainability KPIs

- Cost per pound

- Primary tender acceptance

But modern supply chains generate so much data that it can be tough to know what you really need to pay attention to.

Strong, clear KPIs are crucial for ensuring your network is operating as efficiently and cost-effectively as possible. They are also a key component of any continuous improvement program.

Since not all KPIs are created equal, here’s how nearly 1,000 shippers view the importance of each supply chain KPI:

Download the research study for supply chain KPI insights & benchmarks.

Supply Chain KPI Examples

Let’s dive a little deeper into three of the top logistics KPIs.

On-Time Delivery

It’s the quintessential transportation question: Did it get there on time? It’s not going to be your only concern, but for 58% of shippers, it’s the first.

Why is it important?

Missed appointments can result in late fees and accessorials.

Unreliable carriers can also make planning harder for you, and most importantly, there’s no faster way to sour a customer relationship than to miss your deadlines.

Pro tip: “On-time” is not a universal term.

According to our research, 32% of shippers measure on-time to the day.

Of those that measure on-time to an appointment, 83% give at least a 15-minute buffer.

Cost Per Shipment

This is the combination of all the related costs that go into moving your freight, including the spot or contract rates, the cost of fuel, and any accessorials or late fees.

Why is it important?

A bloated transportation budget will eat into your profits before you know it.

It could also impact operating expenses that could be better spent elsewhere in your organization (marketing, staffing decisions, etc.).

Pro tip: Keeping costs down shouldn’t necessarily be your main goal. Believe it or not, 77% of shippers prioritize performance over cost.

Instead, focus on predictability.

By combining strong reporting with savvy knowledge of freight market cycles and seasonality, you should be able to set a smarter budget.

Freight Tracking Compliance

This goes further than simply knowing whether it’s in-transit or arrived at a facility; shippers today expect to be able to assess progress at any point during a load’s journey.

Why is it important?

It is key to establishing a two-way relationship of trust with your carriers.

Your customers also likely increasingly expect to be able to track their orders’ progress these days, and good carriers should enable you to fulfill that need as well.

Pro tip: Even if they’re not using GPS-enabled tracking, you should expect carriers to enter appointment data like in- and out-times into a platform you can access in a timely manner.

If you don’t have end-to-end visibility though, don’t be too upset. Only 27% of shippers are “very confident” in their freight tracking data.

Sustainability KPIs: A Growing Green Trend

According to our research on supply chain sustainability, 71% of shippers said their organization currently has clearly established supply chain sustainability goals.

KPIs are a critical component of getting towards those goals.

Shippers are tracking these supply chain sustainability KPIs:

- Fuel efficiency (69% of respondents)

- CO2 emissions (60%)

- Alternative fuel usage (52%)

- Personnel skills related to sustainability (48%)

- Fleet age (46%)

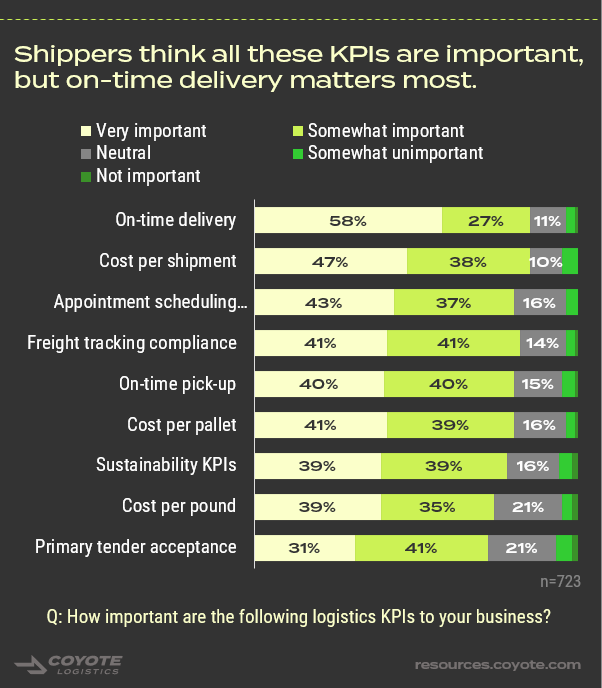

More businesses are also including sustainability as a feature of their transportation RFP process.

While not a requirement for most, it is at least a consideration.

What Makes a Good Supply Chain KPI? 4 Rules

There’s no one-size-fits-all solution for supply chain KPIs — they’re entirely dependent on your needs, your goals, and your processes.

You can follow some general guidelines, though, to make sure you’re setting ones that best serve your supply chain.

1. KPIs should be measurable.

They are data points that can be used to tell a story and should be easily quantifiable.

2. KPIs should derive from your business goals.

They are not goals themselves, and they aren’t used to set goals. If you come up with KPIs in a vacuum, you run a risk of collecting data that will confuse more than clarify.

3. KPIs should be trackable over time.

You should be able to regularly check in to see if your performance has risen, dropped, or stayed level regarding your KPIs.

4. KPIs should have reasonable benchmarks.

Once you have data over time, you should check that against industry benchmarks from your peers.

Want to know what 1,500 shippers & carriers think is reasonable?

Download the supply chain KPI research study.

How to Set the Right KPI for Your Business: Example

Let’s walk through an example of how to align a supply chain KPI with a business goal.

Primary business goal: Delivering orders to your customers faster.

- Don’t: Tracking on-time pickup and delivery for your carriers might seem like a sensible place to start, but they might actually be misleading.

Your overall efficiency in delivering product to your customers doesn’t really have anything to do with whether or not your carriers keep their appointments. - Do: Instead, you would want to set the total time from purchase order receipt to final delivery as a KPI that can truly point to whether you’re meeting your customer’s expectations.

Managing Your Supply Chain KPIs: Who & How to Do It

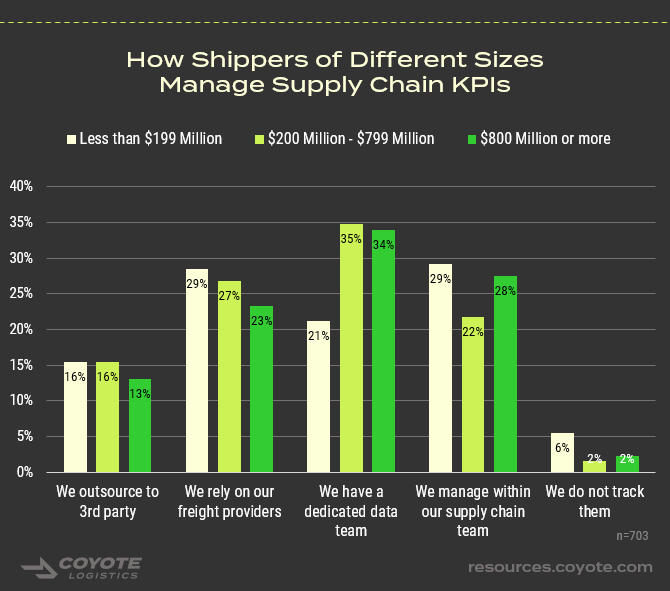

Every organization approaches this differently, and what’s right for you will depend on your business size and supply chain complexity.

You also might rely on different methods for different types of KPIs (e.g., data aggregator for freight tracking, internal team for sustainability, etc.)

Shippers of different sizes use a different mix of outsourcing, freight providers, dedicated data teams and supply chain teams to manage their KPIs.

Download the research study for supply chain KPI insights & benchmarks.

Technology For Supply Chain KPI Management

If you’re worried that you’re way behind the technology curve, you probably shouldn’t be.

Though supply chain automation is growing in the industry, the most common tech tool used for KPIs? It’s actually the tried-and-true spreadsheet — 56% of shippers use manual methods (Excel, email) to manage their data.

Q: Which technology tools do you use to track and manage your supply chain KPIs? Select all that apply.

- Manual (Excel, emails): 56% of respondents

- ERP: 55%

- WMS: 45%

- TMS: 28%

- Control Tower: 15%

n=723

If a carrier has their own system for managing data like appointment entries or in-transit check-ins and you have a TMS, you should be able to connect to them via EDI or API.

You can also have your third-party provider handle this integration with their own system.

It’s Not All on You

Your carriers should be helping you track and manage at least some of your supply chain KPIs.

Many shippers even use a third-party or outsourced logistics provider for their KPI management. This allows you to pass some of this responsibility on to a dedicated team if you don’t have one in house.

If you choose to have your 3PL manage your logistics KPIs, they should have an operations manager or operations lead who can be your KPI point person.

And if they really have their act together, your 3PL team should prepare easily digestible reports on network performance against your KPIs.

According to our research study on outsourced supply chain, 66% of shippers use a third party for at least some of their budgeting and benchmarking, and 70% use a third party for at least some of their reporting and analytics.

Related: 4 signs it’s time to outsource your supply chain KPIs

KPIs in Transportation Bids

If you move enough freight to hold an annual pricing event (a transportation request for proposal or RFP), make sure to incorporate your KPIs into the bid process — 51% of shippers do it every time.

Before anyone starts putting together rates, your carriers should know exactly what standards you’re going to hold them to.

Carrier Scorecards: Keeping Your Carriers on the Same Page

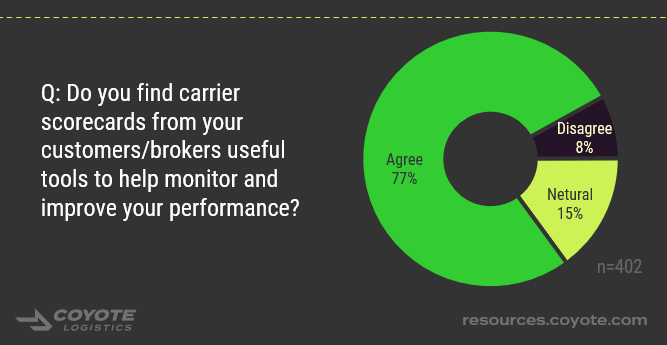

77% of carriers think these are valuable. If you aren’t using them, you should be.

Carrier scorecards put your KPIs in writing, help create realistic and manageable expectations, and set up your entire team for success.

Download the research study for supply chain KPI insights & benchmarks.

How to Use Carrier Scorecards

1. Create your scorecard.

List out the KPIs on which your carrier will be assessed and the benchmarks they’re expected to meet for them.

2. Align with your carrier.

Go over the expectations laid out on the scorecard, answer any questions they have, and have them acknowledge their acceptance of it in writing.

3. Review KPI data with your carrier regularly.

This cadence can vary depending on the specific KPI in question; weekly, monthly or even annual check-ins are normal. Don’t just send them the scorecard, actually meet with them face to face (in person or virtually).

4. Address low performance.

If a carrier isn’t meeting their KPI targets, create a specific, actionable plan for improvement and set up monthly calls to check on their progress.

Pro Tip: Be patient.

It’s OK if it takes a little while to see results from your scorecards.

It’s normal for there to be a baseline period when carriers are still getting familiar with your needs and not quite hitting their targets.

Maintain open communication and have a little patience before you start taking more drastic measures like asking for a corrective action plan.

Avoid These 3 Common KPI Mistakes

Whether you’re new at setting logistics KPIs or you’ve been doing it for a while, it’s always a good idea to step back and make sure you’re doing everything you can to get the most out of them.

Here are some common mistakes we see shippers make when managing KPIs with their carriers:

Setting and forgetting.

The most strategic KPIs can’t tell you anything if you don’t monitor them regularly. Remember to collect data from your carriers at each of your scheduled check-ins.

The silent treatment.

If you see performance slipping, don’t keep it to yourself. Be clear and open with your carriers about whether they’re hitting their KPI targets and what they can do to improve.

Unreasonable expectations.

KPI targets that are too high don’t do anyone any favors. They’ll cause you constant headaches and alienate carriers who may actually be performing capably.

If you avoid each of these pitfalls, you can ensure your KPIs result in actionable data and consistent performance across the board.

Related: Do you know the 15 myths of supply chain KPIs?

Download the Full Supply Chain KPI Research Study

Want to dive deeper into some of the insights here? Want to get industry benchmarks from hundreds of shippers and carriers?