Warehouse Management in the Digital Age: 6 Strategies for Operational Success

Every shipper with an e-commerce component knows that customer buying patterns are inherently volatile.

The COVID-19 pandemic has amplified that volatility to an extreme degree. To manage that volatility, shippers must do everything possible to stay on top of inventory management and prepare for potential warehouse challenges.

Adopting these strategies, though potentially difficult to implement, can help safeguard your operations and keep your supply chain moving.

6 Warehouse Strategies for the Digital Age:

- Spread inventory to get closer to your end customer

- Upgrade your demand planning and WMS technologies

- Use providers that offer value-added services

- Have instant access to flexible capacity

- Leverage data to increase organizational agility

- Use advanced digital solutions for better collaboration

Even if you are unable to make some of these shifts in the current market, these best practices are still valuable when looking to set your strategy for a post-coronavirus world.

1. Spread inventory to get closer to your end consumer

The main challenge that I see shippers facing today—particularly those with a substantial e-commerce component — is deciding how to properly distribute stock keeping units (SKUs) in a way that puts the right SKUs in proximity to the end consumer, without bloating inventory levels.

While fast order fulfillment is contingent on easy access to the right SKUs, striking this delicate balance is especially difficult due to the volatility inherent in e-commerce buying patterns.

The most effective strategy in the age of e-commerce, as many shippers are discovering, is to find ways to spread inventory out around the country.

This approach means holding less overall product in any one location and instead, diversifying across a network of smaller hubs closer to population centers. Though more complex to manage, it allows for much faster fulfillment to meet ever-changing customer demands.

2. Upgrade your demand planning and WMS technologies

Shippers are also experiencing a general increase in total SKU counts and SKU segmentation, which requires more customized supply chain strategies for each product.

Spreading out inventory, moving it closer to end users, keeping levels lean, and managing increased SKU counts and segmentation are only possible with a tremendous amount of supply chain visibility and data connectivity.

To successfully execute these advanced strategies, shippers need to invest in an advanced warehouse management system (WMS) that can link inbound/outbound movements.

According to our third party research study, Technology + Humanity, 87% of shippers currently have some form of WMS, with 41% actively considering other options.

Whether you are in the 13% without a system or are actively shopping around for a new solution, make sure your WMS has the ability to integrate with your other systems (preferably via API).

This is a crucial factor in reducing your own operational complexity. This is also something to consider when evaluating vendors and carriers — can they connect to your system?

System integration is one of the top challenges for shippers. In the same research study, we asked supply chain decision makers where they most need expert help. The top choice? Full software integration across business units.

3. Use providers that offer value-added services

When selecting the right provider, the most prevalent deciding factors are typically location and cost, but there are others to keep in mind.

While each shipper has a unique set of requirements based on their network, across the board, it is advantageous to work with providers that can do more than just the warehousing component.

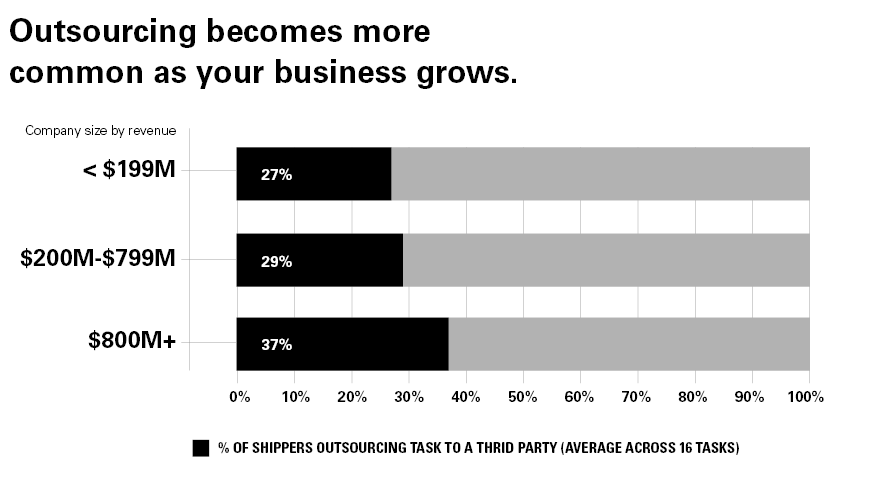

On average, large shippers outsource 37% of their supply chain functions.

Value-added services can include inbound transportation from ports and rail ramps or outbound transportation services, such as warehouse transfers or final mile deliveries.

Managing your warehouse is complex, so any opportunity to streamline your procurement — whether in-house or through a 3PL — is worth seizing, so you can operate more efficiently.

As your business grows in size, take a longer look at outsourcing areas of your supply chain. Going back to our research study, shippers with over $800M in annual revenue outsource around 37% of their total supply chain functions.

4. Have instant access to flexible capacity

Shippers need to work with providers that can help them develop organizational agility and flexible capacity. This has never been more apparent than in the current environment, when shippers’ pain points are being exposed by the unprecedented volatility.

When supply chain disruptions strike, it is important to ask the following questions about your core providers:

- Can they help you adapt?

- Can they source alternative solutions to keep your network up and running?

When budgets and strategies go out the window — like we’re seeing in the post-coronavirus world — can your provider help you develop a new plan of attack in a matter of hours? Are they responsive to your needs?

In order to respond to market fluctuations rapidly and effectively, your provider not only needs deep knowledge of your supply chain, but also expertise in wider, global shipping operations.

If you don’t think your provider has the operational knowledge and capacity to keep your supply chain running when the unexpected happens, it’s time to reevaluate that relationship.

Putting together a new game plan is one thing, having the ability to execute it is another. In order to source alternative solutions, your provider needs a vast, diverse supplier base.

When faced with disruptions, your organization’s commitment to agility and flexible capacity will determine whether you fall short of your commitments and leave behind disgruntled customers or prevail and come out stronger.

If you don’t trust that your provider has the operational knowledge and capacity to keep your supply chain running when the unexpected happens, it’s time to reevaluate that relationship.

Unfortunately, due to COVID-19, nearly every 2020 supply chain strategy went out the window; however, this unprecedented disruption will provide invaluable insight as to how agile and prepared your core providers really are.

And it’s not just for transportation services — digital warehousing is another great way to add flexible, scalable capacity on short notice.

While no provider will be able to mitigate every ripple effect of this global disruption, it is important for you to assess whether or not your providers are doing everything in their power to effectively protect your supply chain.

5. Leverage data to increase organizational agility

Working with flexible providers is a great start, but it’s only part of solution. Modern supply chains are incredibly complex, and the only way take advantage of opportunities and discover bottlenecks is to leverage your own data.

Ask yourself these critical supply chain questions:

- How does product currently move around my network?

- Does it makes sense to build more warehouses to reduce my average length-of-haul?

- What are my service levels to my own warehouses versus by customers?

- Where should I be using different modes?

- Where is speed more important than cost?

- Will I increase efficiency if I use 3PLs to run my warehouse or if I’m in control?

- Does my forecast help me get out ahead of my demand patterns?

If you can’t come up with satisfactory answers, you probably don’t have the right systems in place to collect your data, or the technology and supply chain experts to pull out insights.

Your data will become increasingly important as more advanced AI technologies come into the supply chain — all of which are powered by huge data sets.

If you aren’t collecting it and putting it to good use, you won’t be able to integrate new solutions.

6. Use advanced digital solutions for better collaboration

The digital transformation will continue connecting more — and more minute — facets of the supply chain.

This will allow for greater connectivity between various customers and networks, while enabling “sharing economy” ventures that were not previously possible.

- Efficient consolidation of warehouse space

- Real-time visibility into on-demand available warehouse capacity

- Better network overlays with other shippers and carriers

- Strategic partnerships in warehouse consolidation across similar industry verticals

- Strategic partnerships with the ports to joint-sell to customers

Above All, Keep Listening and Learning

As you implement digital solutions and establish your strategy, never forget the importance of tuning in to the distinct needs of your customer base.

At the end of the day, running an effective business is all about knowing your customers and their challenges and creating strategic solutions to help solve them.

This may seem like an obvious point, but too often, shippers start their strategy by looking at their own needs, rather than considering their customer’s needs first.

Always put your customer at the center of every business decision, and an effective strategy will follow.