What is Outsourced Logistics? The Basics of the 3PL Market

Article Overview

With the rapid rise of globalization, technology and e-commerce, supply chains have become incredibly complex.

Though running an effective supply chain operation is more difficult than ever, it has also never been more important.

To compete in the modern world, shippers have to efficiently manage their inventory and fulfillment.

To do this, most will look outside their four walls for a little help.

It is not realistic (nor a good idea) for most businesses to run 100% of their supply chain operations in-house.

Hiring logistics talent, procuring capacity, investing in physical assets and building technology are all labor-intensive and expensive.

Instead, shippers outsource different parts (or sometimes even all) of their logistics functions to third-party logistics providers (3PLs).

But how do you know what to outsource and what to keep in-house? How many 3PLs should you be using and where?

Before you strategically outsource areas of your supply chain, you need to understand the basics.

What is Outsourced Logistics?

Let’s start with a basic definition.

Outsourcing logistics is when a company uses an external provider (aka a third-party) to handle various supply chain functions.

These can include a mix of shipping, storing, packing and/or delivering a company’s physical goods, from raw materials all the way to the finished product.

The terms “outsourced logistics” and “third-party logistics” are roughly interchangeable — they refer to the same thing.

Outsourcing logistics is when a company uses an external provider (aka a third-party) to handle various supply chain functions.

Size of the Outsourced Logistics (3PL) Market

As supply chains grow more and more complex, business rely more and more on 3PL providers.

From 1995 to 2021, the U.S. the U.S. 3PL market has grown at a compound annual growth rate (CAGR) of 10.2%.

Globally, outsourcing to 3PLs accounts for 12.2% of total logistics costs, up from 10.2% in 2019.

To put that in perspective, in 2021 alone, U.S. shippers spent $339 billion on outsourcing to 3PLs.

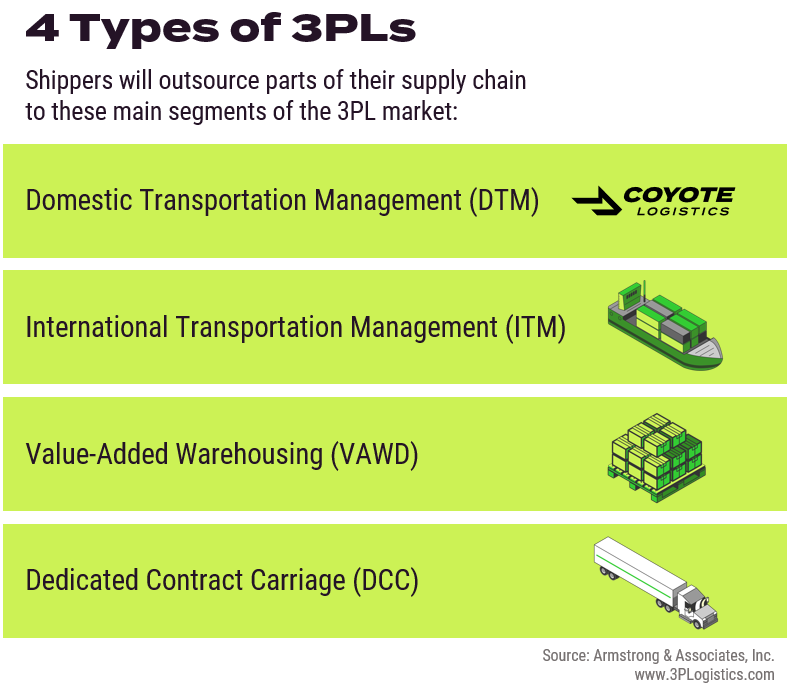

4 Types of 3PLs That Shippers Use for Outsourced Logistics

Armstrong & Associates, the leading research firm on the 3PL market, buckets 3PLs into four main segments that cover most functions of a shipper’s supply chain.

Here is a quick overview of the basic business model for each type of 3PL:

- Dedicated Contract Carriage (DCC):

- Supply shippers with tractors, drivers, and fleet management

- Trailers are normally included

- Contract terms can range from 1-7 years

- Domestic Transportation Management (DTM):

- Provide non-asset based, value-added transportation management services

- Deal mainly with shipments originating in and destined to North American points

- Services are usually performed in conjunction with freight brokerage

- Services are often contractual

- International Transportation Management (ITM):

- Provide non-asset based, value-added international transportation management services

- Services are usually performed in conjunction with freight forwarding

- Services are often contractual

- Value-Added Warehousing and Distribution (VAWD):

- Provide long-term contract warehousing or distribution center operations

- Often include a host of other value-added services

What Logistics Services Do Shippers Outsource?

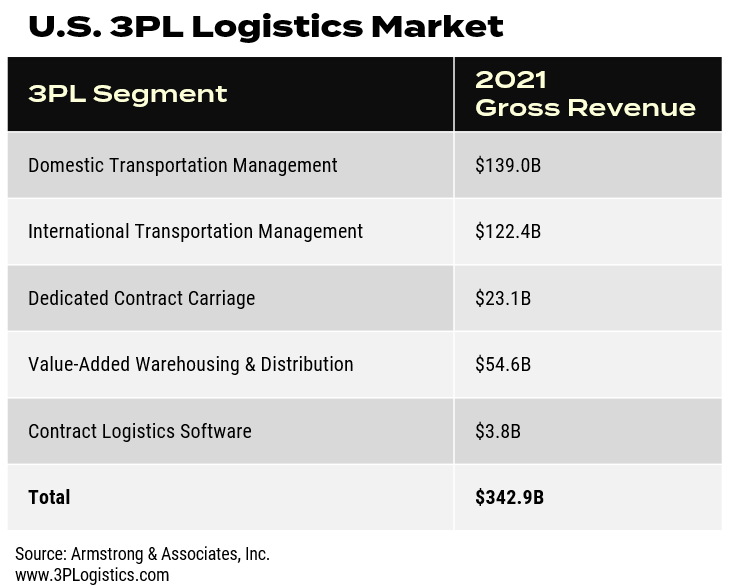

Let’s break down the 3PL market by shipper spend per market segment.

Domestic transportation management gets the biggest share, followed by international transportation management and value-added warehousing.

Transportation Management Services

Transportation management, whether domestic or international, involves the use of sophisticated technology to manage thousands of shipments across multiple carriers and transportation modes.

These services can be as simple as arranging dry van truckload transportation for a single shipment, or as complex as optimizing thousands of shipments across an international supply chain network.

Some shippers will outsource their transportation management in full or in part (outsourcing their RFP management, for instance), relying on a 3PL’s team to execute their day-to-day shipping operations.

Warehousing Services

Shippers often rely on 3PLs to source warehouse capacity, expand their networks, and help them get closer to the end customer.

Warehousing 3PLs tend to be exceptionally good at managing labor across customers, plus, they are typically a more cost-effective option.

As e-commerce causes fulfillment, labor, and other warehousing costs to rise, 3PLs cut costs for individual shippers by offering multi-client warehousing.

Value-Added Warehousing Services

Value-added services are also on the rise due to e-commerce.

This can include a wide array of services, including specialty packaging, inserts, kitting, returns, warranty management and other customized services.

What Industry Verticals Use 3PL Services?

Every industry vertical makes use of 3PLs.

Across the Fortune 500, 92% of companies are outsourcing some portion of their logistics to 3PLs (excluding companies whose business model is not applicable).

In 2022, the technological industry (i.e., electronics, electrical equipment, computers) accounted for the largest portion of 3PL revenues, but retailing, food and grocery and automotive are all top users of outsourcing solutions.

All industries rely on 3PLs, but technological/electronics, retailing, industrial and automotive are the biggest users.

Outsourcing by Business Size

Generally speaking, the larger the company, the more likely it is to rely on outsourced logistics, since larger companies have more complex supply chains, making the resources and expertise of a 3PL more important.

In 2022, 92% of Fortune 500 companies worked with at least one 3PL, which is a significant increase from our initial tracking in 2001, when only 46% of the companies had 3PL relationships.

But working with 3PLs isn’t just for multi-billion-dollar shippers.

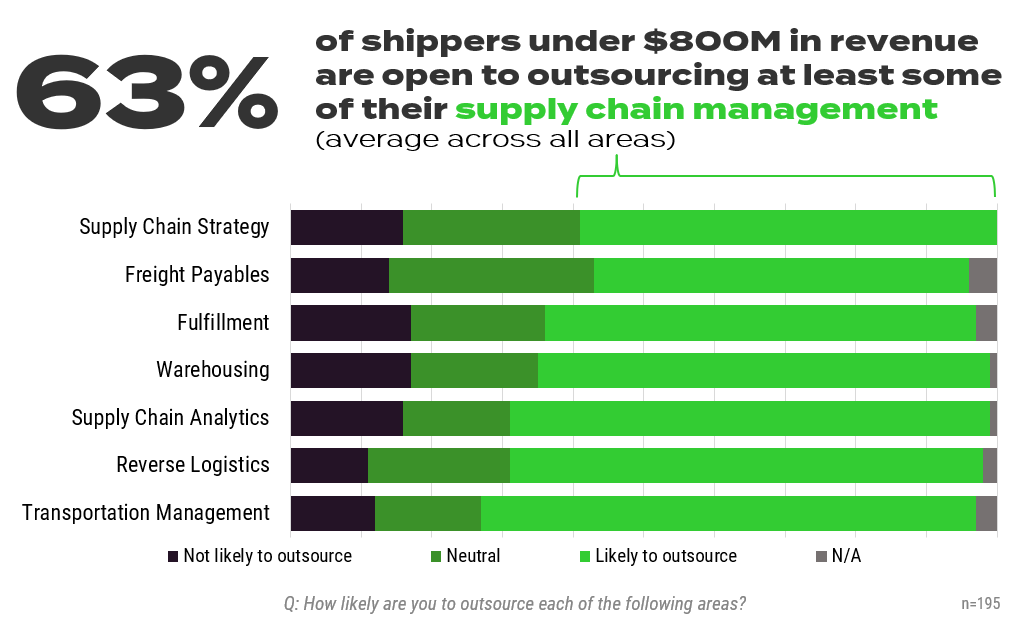

Based on a Coyote research study on supply chain outsourcing, working with a 3PL is a common trend across businesses of all sizes.

On average across seven areas of logistics management, 63% of shippers under $800 million in revenue said they would be likely to outsource to a third party

Get more insights like this in the full Coyote study on supply chain outsourcing.

The Pros & Cons of Outsourcing Your Logistics

While almost every shipper should include 3PLs in their supply chain strategy, outsourcing is not a silver bullet.

There are pros and cons to consider when thinking about what and where to outsource.

Key advantages to outsourcing logistics:

- The ability to focus on core business competencies rather than supply chain operations

- Potential to lower overall transport and logistics costs

- Increased flexibility and efficiency (due to more streamlined operations)

- Improved service levels (leading to increased customer satisfaction)

- Less risk, due to reduced asset ownership and administrative responsibility

Potential disadvantages to outsourcing logistics:

- Loss of control if not managed properly

- Lack of communication/openness by one or both parties can lead to suboptimal operations

- Poor 3PL selection can result in supply chain disruptions, high costs, and lowered service levels

When Should You Outsource?

Shippers are constantly evaluating the “build vs. buy” dilemma: when should I invest in external dedicated support and when I should I develop resources for better in-house services?

Deciding when to keep your operations in-house and when to bring in a 3PL can be difficult. There is no one right answer — the right mix will depend on your supply chain.

Here are some tell-tale signs that outsourcing one or more of your supply chain functions may be a good choice:

- Your company’s overall structure or strategy is changing

- Your logistics costs are rising while your service levels are falling

- You are experiencing rapid growth and need to scale quickly

- You are entering a new market, either business type or geography

- You struggle in recruiting and retaining top logistics talent

- An area of your supply chain needs more flexibility

- Executing supply chain functions is keeping you from core business initiatives

How to Choose Your Outsourced Logistics Providers

Before contacting 3PLs, it’s important to define your expectations and outline what you want to achieve. Asking the right questions is an important precursor to a successful working relationship.

Look for 3PLs that best align with your company’s goals. Assess each 3PL’s service offerings and solutions as well as its IT capabilities and level of digitization/automation.

Make sure to thoroughly evaluate each 3PL’s overall strengths and weaknesses before choosing to work with them.

It’s common for shippers to use a variety of 3PLs, as providers have varied expertise in certain market segments, geographies, and industry verticals.

Factors to consider when choosing a 3PL:

- Industries they serve

- Specializations and certifications held

- Current and past customer reviews

- Continuous improvement initiatives and participation

- Focus on quality and performance

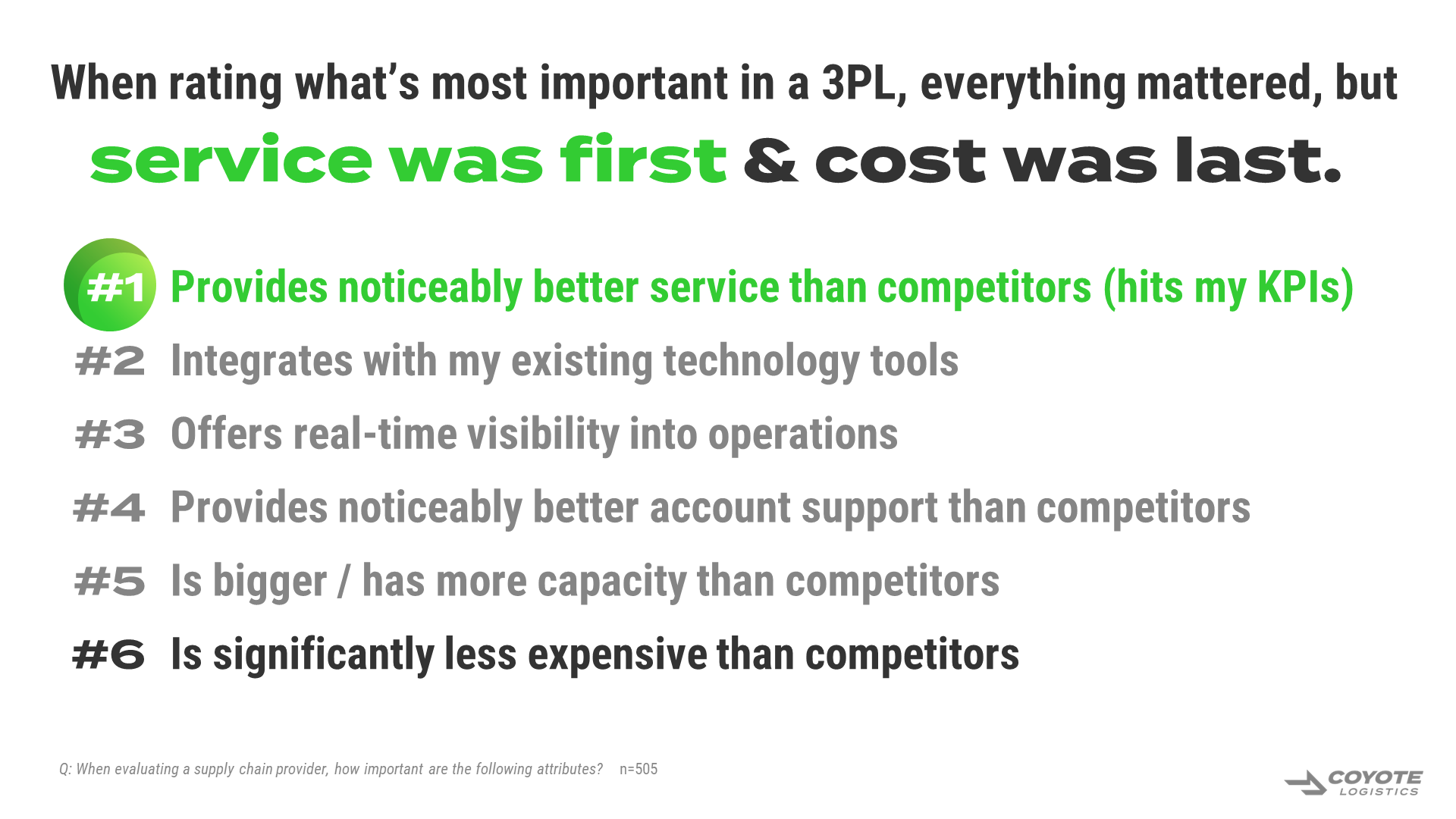

According to over 500 shippers in a Coyote study on supply chain outsourcing, providing superior service was the most important aspect of choosing a 3PL.

Get more insights like this in the full Coyote study on supply chain outsourcing

Run an RFP to Choose Your 3PL Providers

Running an RFP is an effective method of evaluating potential 3PLs, assessing their capabilities and determining the best fit for your business needs.

The most important part of your RFP is to make sure it includes critical information.

Supply Chain Data to Include in Your RFP:

- Order/shipment data from a freight bill payment company (this can help facilitate a good bid response from transportation 3PLs)

- Warehousing information — such as receiving, storage, picking, shipping volumes and item types

- Good descriptions, weights, and dimensions of products handled

To make sure you’re getting competitive rates and service, get new bids for your outsourced solutions on a regular basis.

In the transportation sector, shippers need to re-bid their outsourced solutions every one to two years. A lot of contract warehousing agreements are renewed in 3-year agreements.

Related: 7 Steps to a Better RFP

Get Started with Outsourced Logistics Solutions

Running a modern supply chain is complex and difficult, but shippers do not need to go at it alone.

Shippers large and small rely on 3PLs to help them ship smarter, and this trend is only continuing to grow.

Working with strategic 3PL providers and outsourcing components of your supply chain operations will help you quickly gain expertise and technology while freeing up your people to focus on your core business objectives.

Want a Deeper Dive on the 3PL Market?

Now that you have a foundational knowledge of outsourced logistics, you can dive deeper into industry data. Armstrong & Associates is the leading research firm on third-party logistics, and they offer in-depth market analysis, competitor profiles, and trend reports.

If you need expert research to help you set your 3PL strategy, check out their latest research.