How to Start a Continuous Improvement Program: 6 Simple Steps for Your Supply Chain

Implementing a continuous improvement program at your company can seem like a daunting project, but it isn’t as difficult as it sounds.

Making small, incremental changes can produce dramatic results, and I promise that the benefits far outweigh the effort.

Want proof?

When we revamped our own internal continuous improvement program, in less than 1 year, we:

- Completed 260 projects

- Eliminated 270 weekly hours of redundant and unnecessary tasks (that’s ~19,000 annual hours)

- Increased employee engagement

And you can make these operational improvements in any market conditions.

In 2020, despite the COVID-19 pandemic and a remote workforce, we completed 132 continuous improvement projects, saving us an estimated 120 hours per week in non-value adding tasks.

What You Need to Start Continuous Improvement at Your Business Your Business

If you are willing to commit to a consistent, structured approach, you too can implement a continuous improvement program that will make your supply chain operations more efficient.

Let’s take look at:

- What continuous improvement is

- Why it’s worth your time

- 6 key phases of continuous improvement (using a real-life example)

What Is “Continuous Improvement”?

Continuous improvement is a proactive approach to superior customer service which prioritizes the elimination of waste and relies on active employee involvement to develop solutions to challenges as they arise.

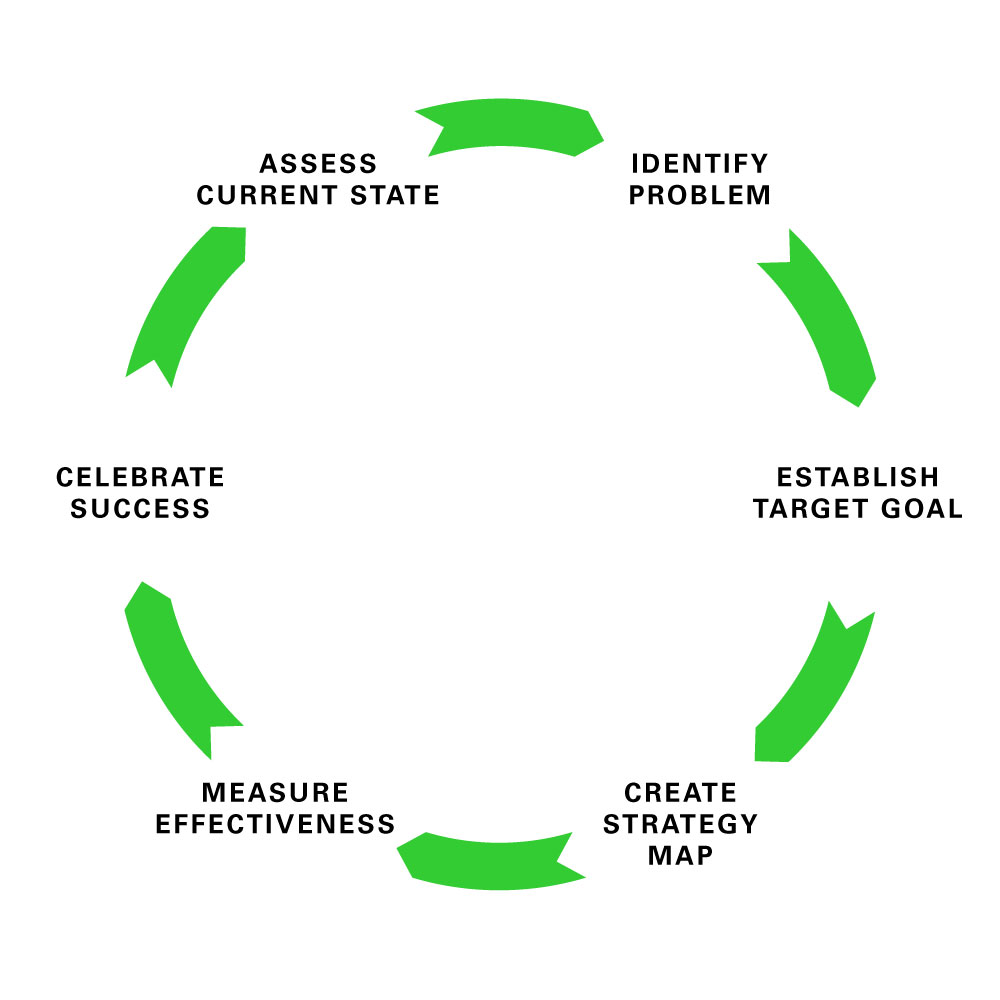

Continuous improvement involves six distinct phases that seek small improvements in processes and products, with the objective of increasing quality and reducing waste.

Additionally, this process is distinguished by:

- An ongoing cycle of positive change and employee involvement

- A metrics-driven process to continually review and improve performance

- A step-by-step incremental improvement strategy

The following basic principles of operational excellence are small, simple process improvements that can make your business more efficient, regardless of size or industry.

Small Changes, Big Results

Some continuous improvement projects are large-scale operational overhauls, but a vast majority are small, incremental tweaks implemented by core team members within each department, rather than throughout the entire organization.

A successful continuous improvement program doesn’t rely on leadership making big strategic decisions, but rather, enlists front-line employees and managers to implement small improvements that snowball into measurable results.

Small tweaks driven by front-line employees are the basis of a successful Continuous Improvement program.

Laying the Groundwork for Continuous Improvement

Here are a few key premises to keep in mind as you set up your Continuous Improvement program.

Curiosity and dedication are foundational elements of continuous improvement.

The first objective of continuous improvement is to discover organizational gaps that bar you from achieving greater productivity and success. This discovery process requires commitment and curiosity.

Pose a simple question or two at the beginning of your process.

Central question(s): What barriers are keeping us from optimizing our supply chain operations? How can we eliminate our waste and inefficiencies?

Conducting an objective investigation of your current systems and processes is imperative.

Develop a clear inquiry that addresses your proposed “fix.” This is paramount to the effectiveness of continuous improvement.

Hypothesis: We lack a consistent, structured approach to analyzing challenges and developing solutions.

Clearly state your goal and share it widely with everyone involved.

Goal: Create a culture of continuous improvement that helps deliver a best-in-class product for both internal and external customers.

PARS: What Are They & Why You Should Use Them

We recommend utilizing PARS (Problem/Action/Results Statements) to help you clearly catalogue your process — what core issues did you identify, what actions did you take to attempt to solve them and how did your plan work out?

PARS provides a summary of your operations issue by clearly defining the:

- Problem you are facing

- Actions taken to address the problem

- Results achieved through your continuous improvement process

The 6 Phases of Continuous Improvement

- Assess the current situation

- Identify the main problem

- Establish a target goal

- Map out a strategy

- Measure effectiveness

- Celebrate success

Now that you have the basics under your belt, let’s dive into the 6 phases of Continuous Improvement by walking through a real-life example.

Summary of the Issue

A food shipper was spending $98,000 annually in avoidable accessorials on USDA (United States Department of Agriculture) shipments due to poor appointment scheduling at a facility.

Here are the details:

- A large national food distributor (one of Coyote’s managed transportation shippers) was having appointment scheduling issues out of a facility on their USDA shipments.

- These shipments required a USDA inspector to be on-site at the facility when the driver arrived for pick up, meaning careful coordination of scheduling. This was not happening.

- There was a disconnect between the food distributor, the facility, the customer service reps and the carriers. Carriers would routinely show up to the facility when no USDA inspector was on-site, due to incorrectly set pick up appointments.

- Appointment scheduling is a common logistics issue, but this small problem cost the food distributor $98,000 annually in accessorials.

This situation was the perfect candidate for a continuous improvement project.

Phase 1: Assess Current State

Acknowledging the current state of your operation will make it easier to distinguish the pain points and then implement improvement strategies.

In this scenario, we observe:

- Carriers are having trouble scheduling shipping appointments

- There is a procedural disconnect between the food distributor, the shipping facility, the Coyote operations team and the carriers

- Missed pickup appointments are a regularity

- Roughly $98,000 in accessorials ( i.e. Truck Orders Not Used, or TONUs, layovers, detention, etc.)

- Less than ideal delivery appointments

Phase 2: Identify Main Problem

The problem should address the discrepancy between where you are and where you want to be.

This is the first step in the PARS process.

In this scenario, the main problem is:

- Systemic miscommunication resulting in pickup appointments for USDA loads when no USDA inspector would be on-site, leading to the driver not getting loaded.

Phase 3: Establish Target Goal

Before mapping out a solid improvement strategy, it is important to establish your target goal(s) so you know what to work towards and how to measure progress.

In this scenario, our goals are to:

- Eliminate avoidable accessorials

- Streamline communication between all parties involved on the food distributor’s USDA shipments

- Coordinate the schedules of all parties involved

- Improve operational efficiency

- Increase on-time pickup performance

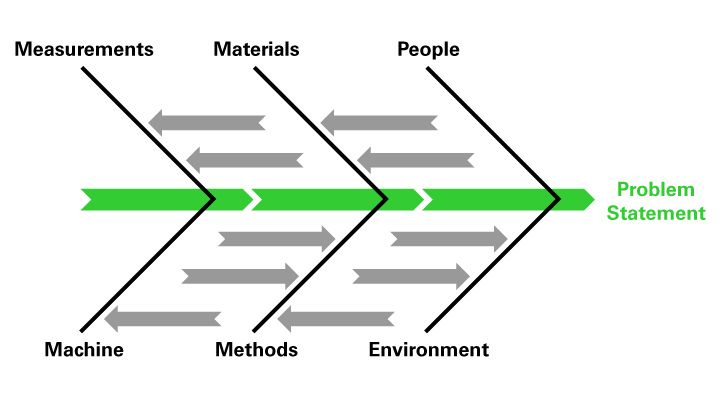

Phase 4: Map Out Strategy

Including team members in the strategy mapping process is incredibly important, as it increases buy-in and boosts morale.

We regularly check-in on core metrics and in this case, noticed increased accessorial spend on these shipments. To examine the cause of this, we took the following actions.

Here is a look at our approach:

- Utilized the Fishbone/Ishikawa Diagram internally so each team member could contribute their ideas and develop a coherent strategy (i.e. determine core parties involved, propose solutions, note the benefits and challenges of arriving at a solution)

- Conducted weekly meetings for team members to share their observations and brainstorm solutions

Phase 5: Measure Effectiveness

In order to gauge the effectiveness of your improvements, it’s important to analyze the effectiveness of your actions in relation to your target goals.

Keeping close tabs on your logistics key performance indicators (KPIs) is incredibly important part of a continuous improvement program.

You should track projects and measure improvements on a monthly, quarterly and annual basis to maximize the impact of the continuous improvement process.

Analyzing actions taken is the second step in the PARS process.

In this scenario, our operations team took the following actions:

- Coordinated a call with our contact at the food distribution company to talk about the patterns we were noticing and the issues we observed

- Talked to carriers and the facility and noted that issues were arising because they could not connect with a USDA inspector on-site

- Requested a different pickup time from the facility, which shifted our pickup slot to a more agreeable time in order to reduce missed pickups and accessorials

Phase 6: Celebrate Success

Celebrating the success of your new procedures and strategies is a significant phase of the continuous improvement process.

This is also an opportunity for strengthening your organization while fostering a team-oriented culture comprised of individuals committed to ongoing improvement.

Recording and reporting your results is the third step of the PARS process.

Here are some of the results we achieved in this scenario:

- Saved the food distributor roughly $85,000 per year

- Decreased the month-over-month accessorial spend for USDA orders to 84.81%

- Eliminated 4 hours per week in unnecessary email exchange, previously dedicated to resolving day-of delivery issues

- Significantly decreased email volume for the Coyote operations team, the customer and the carriers

- Decreased USDA accessorial requests related to product not being ready when incorrectly scheduled in the past

How to Celebrate Success

To celebrate success, our team regularly:

- Distributes department-wide emails (monthly, quarterly and annually) to recognize operations teams with the highest average number of projects per rep

- Recognizes individuals who conceptualized and managed the highest number of projects

- Gives reps the opportunity to present their projects to senior leadership for feedback

- Allows monthly team winners to present the PARS for their project

- Gives quarterly team winners a one-time team bonus

- Provides the annual team winner with a team dinner

- Awards the annual individual winner with a one-time annual bonus

Creating a Culture of Continuous Improvement

For us, the most important part of the continuous improvement process, from a leadership standpoint, is to empower individuals to make decisions and improve inefficiencies on their own.

Everyone in our organization has the capability to suggest and implement changes, and that impacts our entire culture.

New reps are introduced to continuous improvement in their onboarding, and every team member is included in weekly departmental whiteboarding meetings that are dedicated to continuous improvement efforts.

Continuous Improvement is a part of our culture: everyone in our organization is accountable for suggesting and implementing changes.

The quantitative results of even the most basic improvements allow team members to track their success and see how their incremental improvement projects produce impactful and lasting change.

- Internally, this makes it a lot easier to secure buy-in among our team members because they are excited about the results of their ideation and implementation.

- Externally, our customers are able to see the clear value we provide to them because of our commitment to cost-savings throughout the continuous improvement process.

Commitment Is the Key to Success

Creating a culture of continuous improvement within your organization takes commitment, but it is possible, and the results are worth it.

And remember, the continuous improvement process depends on just that: improvement that is continuous in nature. An explosion of quick wins, while exciting, is not a compelling reason to abandon the structure.

You can experience the same dynamic results, with minimal to no additional programs, services or employee headcount.

It all begins with curiosity, clear goals and a commitment to seeing your progress through.

Need help implementing a Continuous Improvement program in your supply chain?

Coyote can help. Talk to a managed supply chain specialist to get started.