5 Ways Retailers Use Flexible Capacity to Manage Shipping Spikes

Every retailer has a peak season.

For many, it’s peak retail season, which sends shippers scrambling to line up capacity to meet high Q4 demand.

While retail and e-commerce shippers experience the most drastic surges, the year-end spike has a ripple effect across every industry as carriers move to service high-volume holiday shippers.

Regardless of when your business has shipping spikes, creative capacity solutions can help you manage these special shipping projects with ease.

Here are five ways you can manage high shipping volume when your demand spikes.

1. Leverage power only capacity to move your trailers.

Loading a dropped trailer is one thing — finding a driver to deliver it is another.

Many shippers own or lease their own trailers but need additional help to move product throughout their network.

Through years of coordinating transportation during Peak Season, Coyote has developed a dense network of power only capacity.

During Q4, Coyote moves over 1,500 power only loads every day.

Whether you need to stage equipment for surges, rebalance your network or deliver to retail locations, we can quickly procure power only carriers for your needs, including all of the following services:

- Local shuttle runs – regional or cross-country

- Team drivers for expedited freight

- Dedicated day rates for projects

- Service in any region

- Short lead time accommodation

2. Access additional trailer capacity.

When volume spikes during Q4, many shippers need to grow their trailer pool. Finding short-term lease options on trailers — especially on short notice — can be difficult.

We can also leverage our relationships with trailer leasing companies to help shippers tap into the following offerings:

- On-demand trailer capacity

- Temporary drop pools

- Short-term rentals

- 100,000+ trailers from leasing companies

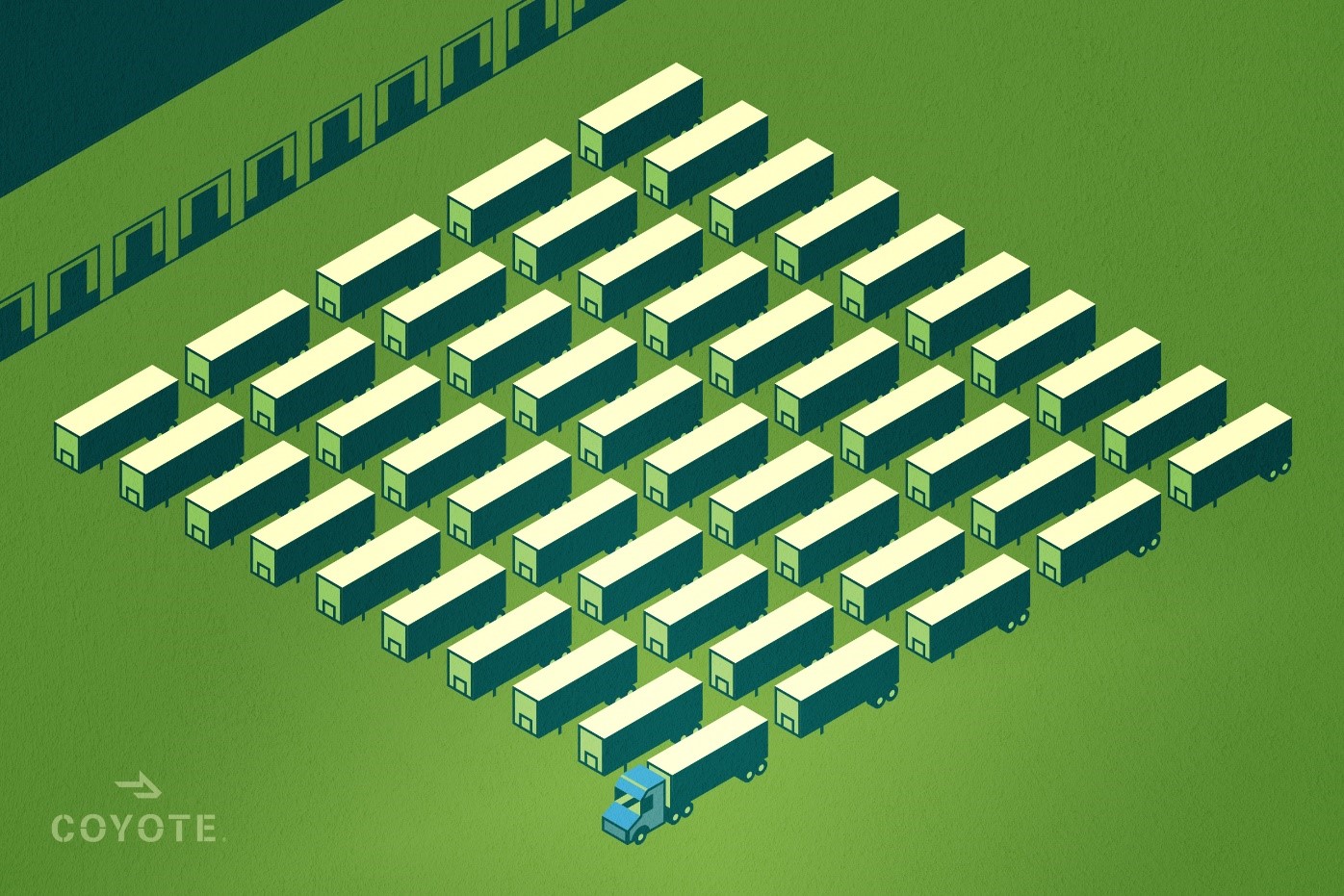

3. Combine power only capacity and leased trailers for mobile storage solutions.

With an anticipated influx of demand, retail shippers prepare by building inventory. As warehouses become cramped, shippers need to move inventory off the dock, though it may not be ready to hit the shelves in stores.

Mobile trailer storage is a solution that can clear rack space in the warehouse, stage product for on-demand delivery and hold product until the store or fulfillment center is ready to receive it.

Coyote can leverage our relationships with trailer leasing companies to increase our asset volume by thousands and help shippers access alternative storage solutions.

Here’s how one global apparel retailer used mobile storage to deliver during the holidays.

Challenge:

The apparel company needed an asset-based solution to cover 50 loads out of one warehouse for an end-of-year product push.

The catch? For warehouse space and accounting purposes, they needed to load the product at least two weeks prior to shipping without knowing exactly when or where the product would go.

Furthermore, the shipper needed the trailers on short notice, right when capacity was toughest to source — during Q4 in southern California.

Solution:

At a time when no other carrier could provide the necessary capacity solution, Coyote procured trailers and tapped into our dense power only carrier network to drop all 50 trailers in less than a week.

The shipper loaded the trailers, and Coyote stored them in a secure yard until they were ready for delivery.

With less than 24 hours’ notice, the shipper told Coyote where the product needed to ship. We sourced the necessary driver capacity to deliver the loaded trailers to their destinations.

4. Use a dedicated team for surge shipping projects.

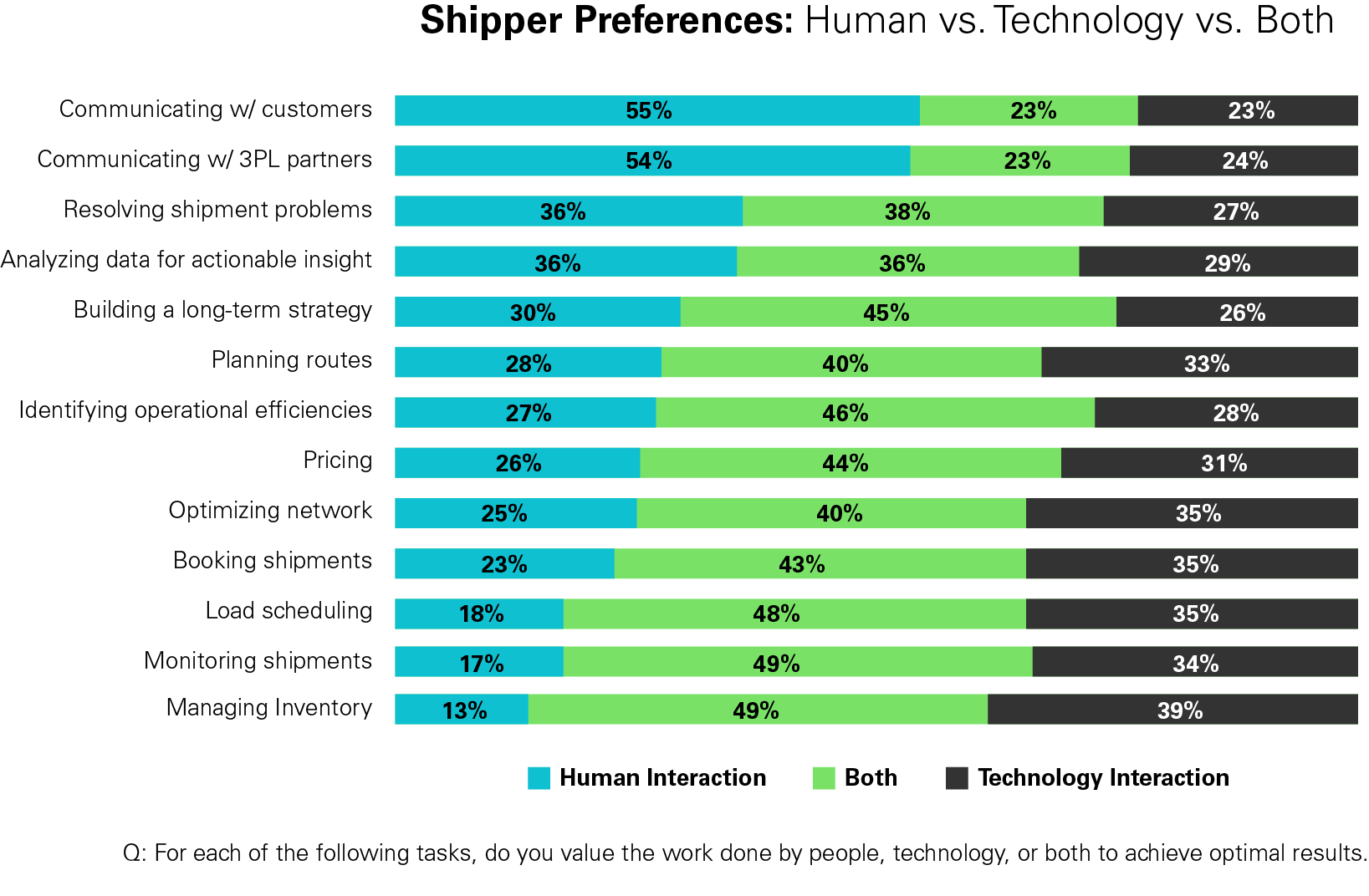

According to our third-party market research study, every supply chain task requires a balance of smart people and innovative technology.

Across 13 different tasks, there was not a single one where the majority of respondents preferred technology alone – human interaction or a combination of tech and humans were the top choices.

Shippers with increased holiday peak season volume require additional equipment and capacity. Depending on the intensity of their shipping spike, some need to supplement their regular operations with more talent.

It is not always practical or feasible to bring on a whole team to support surge shipping projects. To help fill in the gaps, Coyote provides shippers with on-demand teams of logistics specialists.

We model custom solutions based on our Peak Season operations to help shippers tackle big projects. See how we helped a national tire distributor execute a warehouse transfer – we relocated 55,000 tires in three days without disrupting service to their customers.

“Coyote coordinated a dedicated pool of contracted carriers, along with on-site representatives. We felt confident in meeting the unique requirements of this inventory transfer because we had an experienced single point of contact overseeing it.”

– Regional Transportation Manager, A National Auto Tire Distributor

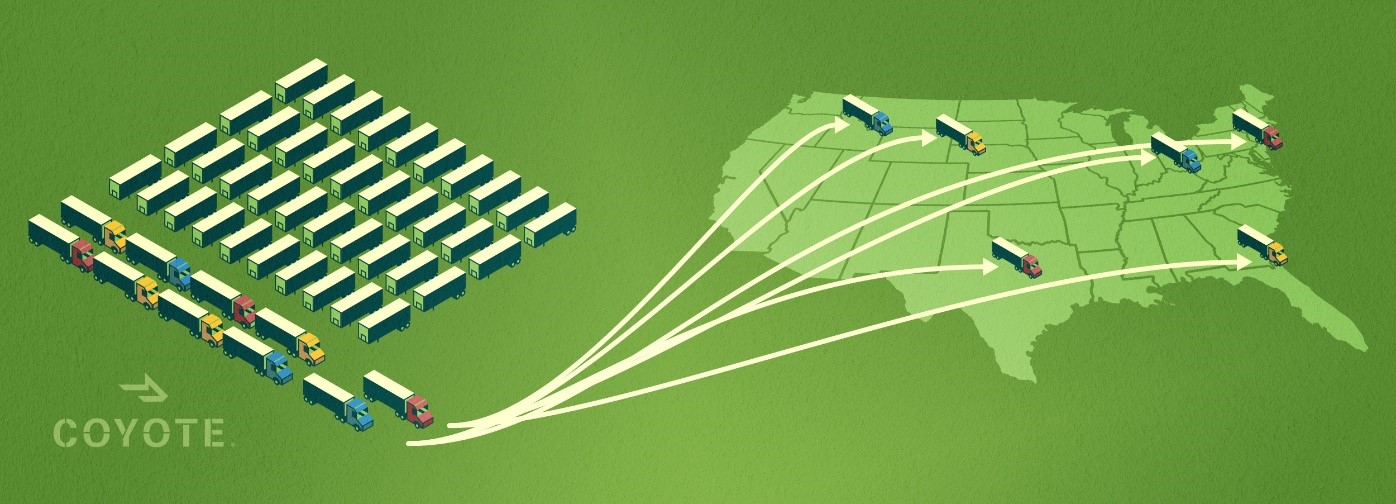

5. Tap into a flexible carrier network.

Holiday shipping can be volatile — stockpiling capacity isn’t necessarily the answer. During peak retail season, flexibility is a top priority.

As volumes ebb and flow and destinations change, shippers need capacity responsive to shifting needs. Coverage that scales up and down with demand can help shippers avoid over-committing without being exposed.

Working with a flexible 3PL provider can alleviate some high-volume demand stresses. Coyote has the expertise, network scale and service diversity to help shippers navigate Q4, including the following offerings:

- Power only

- Trailer leasing

- Expedited team drivers

- Dedicated drivers

- Pop-up fleets

- Temporary drop pools

- Mobile storage

Keep Learning about Outside-the-Box Capacity Solutions

To manage shipping spikes — whether during Q4 holiday retail season, or whenever your business surges — shippers are making use of a few creative capacity solutions:

- Leveraging power only capacity to move your own trailers

- Accessing leased trailer capacity

- Combining power only & leased trailers for mobile storage

- Bringing in a dedicated team for special surge shipping projects

- Tapping into a flexible carrier network

Learn more about our special freight project capabilities.

Explore Freight Projects With Coyote