A Tale of Two Markets: 53’ Domestic vs. 40’ International Intermodal Containers

If you’ve mastered the basics of intermodal shipping, it’s time to get a little more sophisticated.

Did you know, for instance, that not all intermodal containers are the same?

If you’ve only been shipping your intermodal freight in 53’ domestic containers, you might be missing out on opportunities to save some money.

But the 40′ and 53′ intermodal markets are not the same.

There’s a few things you need to know first.

Learn everything you need to know to get started:

Domestic Shipping Containers (53′): The Most Common Way to Ship Your Intermodal Freight

Most of the intermodal containers riding the rails in the U.S. are domestic shipping containers — there are roughly 336,500 of them on the rail today.

They’re either owned by asset-based intermodal providers (e.g., J.B. Hunt), or are part of container programs that are jointly owned and operated by Class 1 railroads (e.g., the Union Pacific).

Shipping with an asset-based intermodal carrier? Your freight will typically ride in one of their containers.

Shipping with an intermodal marketing company (IMC), AKA a broker or 3PL? Your freight will typically ride in a rail-owned container.

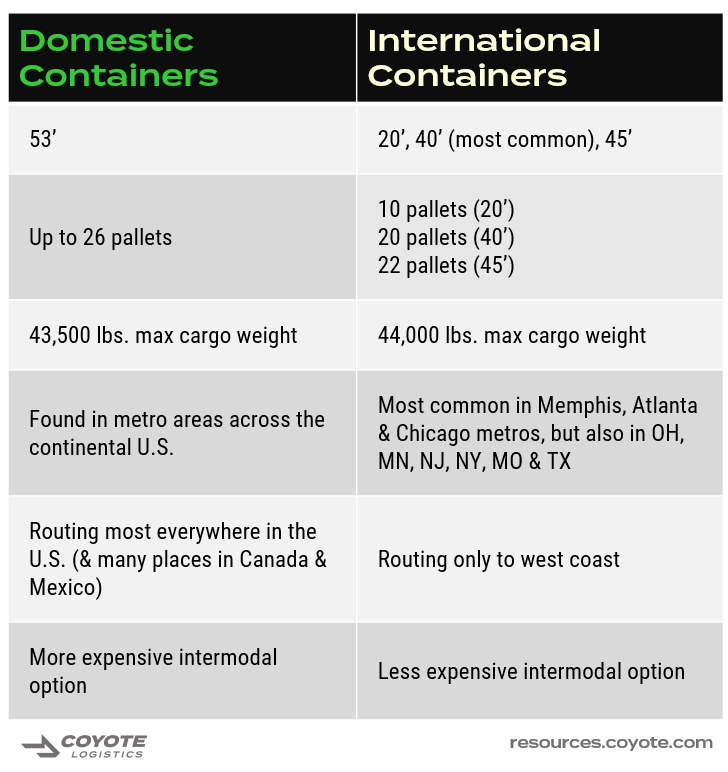

Domestic Container Overview

Regardless of whether you’re using an asset-based carrier or an IMC, here’s what you can expect when shipping in a domestic container.

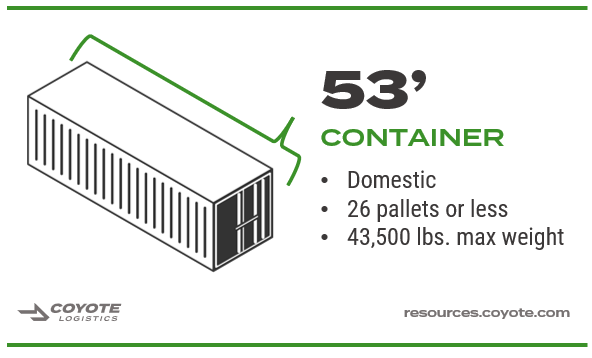

A 53’ shipping container.

Domestic intermodal containers have almost the same dimensions as a 53’ dry van trailer used for full truckload shipping — it’s why intermodal can be thought of as a truckload conversion product.

Space for 26 pallets.

Again, this is the same volume of freight you’ll typically ship in a truckload.

A slightly lower max weight than full truckload shipping.

While dry van trailers can haul a maximum of 45,000 lbs. of freight, intermodal containers — made from heavier steel needed for double-stacking — usually top out at 43,500 lbs.

Point-to-point shipping anywhere in the U.S.

Domestic containers are specifically made to transport goods across the U.S. (and many points in Canada and Mexico as well. There are far less restrictions on routing.

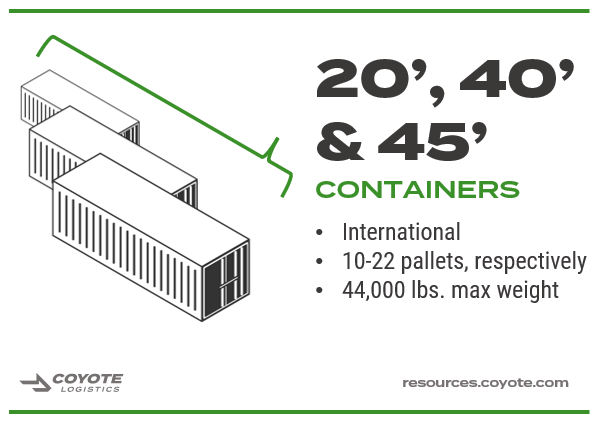

International Shipping Containers (20′, 40′ & 45′): 3 Sizes to Fit Your Needs

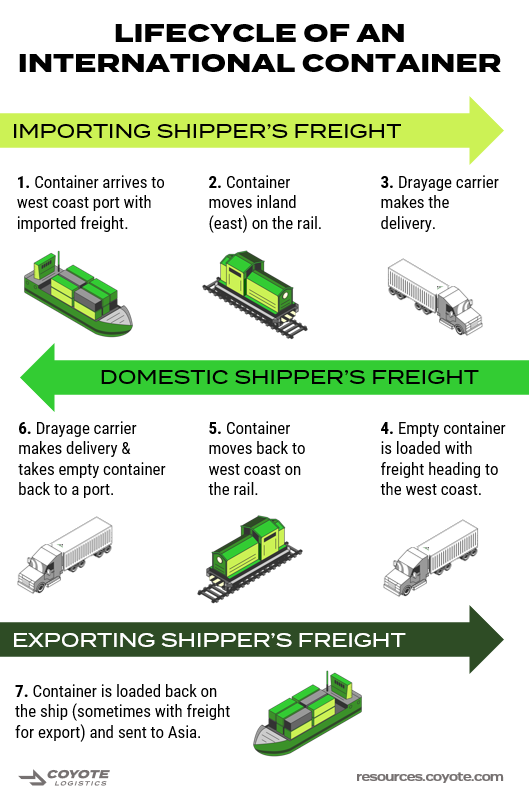

As their name implies, international shipping containers aren’t intended to remain on the rails in the U.S.

They come into the country via international container shipping companies (also called steamship lines) carrying overseas freight into a U.S. port.

From the Port to Inland Destination

The majority of this freight — roughly two thirds of it — is imported from Asia and enters the country through West Coast ports (Long Beach/Los Angeles, Oakland, Portland, Seattle).

Most containers arrive at the port where they are pulled off the ship and immediately unloaded. The freight is then transloaded into a warehouse for storage, or into a domestic rail container or a truck for inland transportation.

Historically, around 30% of import containers are sent directly inland on the rail (although that number dropped sharply at the end of 2021).

From the Inland Location Back to the Port

Once international containers are unloaded at their final destination, it’s up to their owners to get them back to the west coast ports so they can return across the ocean.

While the shipping lines will send the containers back to the west coast empty if necessary, they welcome opportunities to get backhaul freight.

That’s where IMCs come in — IMCs work with many shippers and can identify opportunities to find freight to match the lane.

Why ship in a 40′? Shippers get a cheaper rate while the ocean shipping line makes a little revenue getting their equipment back to the port — it’s a win-win.

International Container Overview

If you ship your freight in an international container, here’s what you’ll likely get.

A 20’, 40’ or 45’ container.

Once the standard, 45’ containers have largely gone by the wayside in favor of the 20’ and 40’ boxes. These can be easily stacked in a modular fashion on a cargo ship. The most abundant international shipping containers by far are 40′ containers.

Options for 10-, 20- or 22-pallet shipments.

That said, you’re most likely looking at 20-pallet opportunities in those 40’ containers.

Maximum weight of 44,000 lbs.

Note that 40’ containers can hold more freight weight than domestic 53’s because there’s less steel box adding to the total weight. They’re great for dense intermodal freight.

Mostly West Coast-bound opportunities.

Almost all international container opportunities need to head West towards ~100 miles of Los Angeles, Northern California, Portland or Seattle (but some opportunities do exist in other lanes).

Did you know we work with OpenTrack to provide total visibility for ocean container moves? If you’re shipping in an ocean-bound international container, you can get updates from all ports and terminals your freight passes through. Talk to your rep to get set up with OpenTrack.

Domestic vs. International Containers: Key Differences in Your Shipping Experience

To the end user, the process of moving freight in a domestic container vs. an international one is very similar.

The major differences between full truckload shipping and intermodal all hold true for both types of containers; however, there are a few additional wrinkles when you ship in international containers.

Chassis are sourced separately (and can be harder to find).

While the railroads handle all chassis for domestic shipping containers, shippers and drayage carriers are most often responsible for sourcing them from a third party for international containers.

Drayage capacity can be less consistent.

Many drayage carriers will specialize in either port work or rail ramp (domestic).

Given the supply chain disruptions of the last several years, many drayage carriers don’t want to get tied up in a port (it’s usually a much longer process than going to an intermodal ramp).

For that reason, it may be harder today to find ones who are willing to haul 40’ trailers that might take them to a port (at destination, after they make the delivery).

20’ containers are loaded onto the train in pairs.

If you’ve only filled one of them with your freight, it may wait for a while at the intermodal ramp for another container to match it with.

There are more usually more accessorials.

With domestic containers, the chassis are at the rail ramp and the container’s final destination is back at the ramp.

International containers often involve chassis splits (bringing a chassis from a different location than the container) and pier termination fees (to cover the cost of getting the empty container back to the port).

But even with these taken into account, your total cost is almost always still lower in a 40’ container than a 53’ (or a truck). Additionally, a good IMC will account for this in your pricing up front.

Pricing & container availability is dependent on the import market.

Some regions are more likely have 40’ container capacity than others.

And if imports are down to that region, there will be fewer containers available. Because the 40′ market can be a little more opportunistic, sometimes you may want to plan intermodal pricing for both 53′ and 40′ options depending on market conditions.

Routing is more restrictive.

While 53’ containers can be sent basically from anywhere to anywhere else in the U.S., 40’ containers typically need to be headed back toward the West Coast.

They also are restricted to certain rails because of exclusivity agreements some railroads have with domestic carriers.

3 Ways to Take Advantage of International Container Opportunities

If you think your freight could be a fit for 40′ containers, there are a few steps you can take to be an informed shipper and position yourself for better opportunities.

1. Work With an IMC

If you want 40′ shipping containers to even be an option, this is your best bet for getting access to them.

2. Know Your Weight and Volume

With this data ready and accurate at the moment you request a quote, your provider will be able to assess right away whether your freight will fit in a 40’ container.

3. Do the Math for Long-Term Opportunities

If you have consistent freight volume running in 53’s, you may be able to cut a few pallets out per shipment and convert to 40’s — you might be able to save money in the long run.

When to Use a 40’ Container

- You’re shipping from a metro area in the East, Midwest or South

- You’re shipping toward the West Coast

- You have 20 pallets or less of freight in your shipment

- Your freight weighs 44,000 lbs. or less.

Ready to Box It Up? Get an Intermodal Quote

As a leading IMC, we’re proud to offer access to tens of thousands of both domestic and international containers.

If your intermodal freight will fit in a 20’, 40’, 45’ or 53’ box, we’ll make sure it hits the rails in one.

Talk to our intermodal specialists today to learn more about our rates and service offerings, or request a quote if you’re ready to get it rolling.