Shipper of Choice Do’s and Don’ts: 9 Best Practices to Improve Carrier Relationships

Shipper of Choice.

In any market conditions, you should strive to be the kind of business that freight carriers want to work with.

But in a tightening market, standing out as a shipper of choice is more important than ever. You don’t want to find yourself unable to find a reasonable rate, or worse — unable to secure capacity at all.

But what exactly is a shipper of choice? And how do you become one?

When carriers have the luxury of choice (when there’s more demand for carrier services than supply in the market), you need to make your business and your freight as attractive to them as possible.

Luckily, there are some strategic supply chain operational adjustments — big and small — that you can make to help position your company for long-term success.

By implementing these shipper of choice do’s and avoiding the don’ts, you can become a more desirable customer for freight providers now or in any market condition.

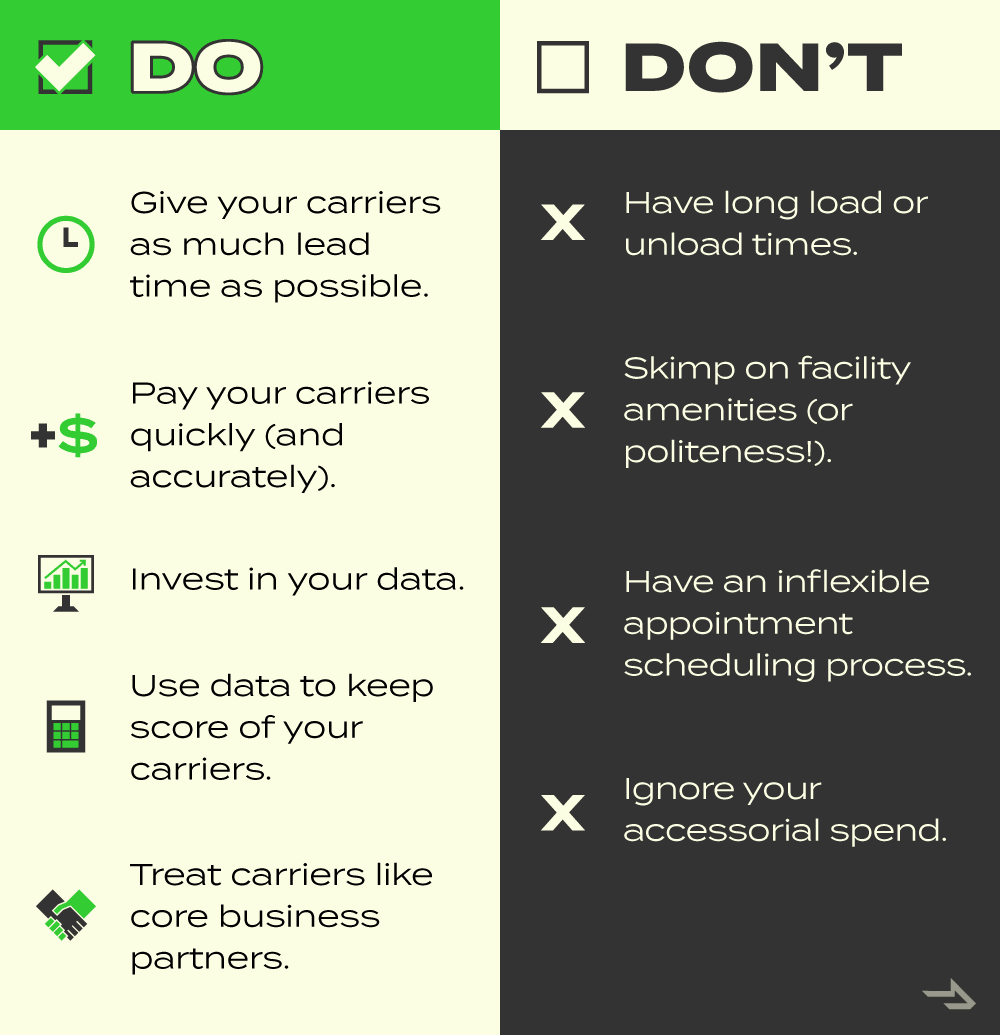

Shippers of Choice Do:

Give your carriers as much lead time as possible.

Imagine you’re flying across the country to see your friends and family the Wednesday before Thanksgiving — notoriously one of the busiest travel days of the year, possibly the busiest.

You’ve asked around and found a reliable friend to come pick you up from the airport. They’ve asked you to send your flight details in advance, so they can plan for what airport to pick you up at, what route to take to avoid the most traffic, and when to leave to avoid sitting and waiting in the cell phone lot.

Would you leave your friend hanging by sending your flight details at the last minute? Likely no, you would do everything you could to make picking you up as easy as possible.

We realize that it’s not always realistic to know shipping schedules ahead of time and that last-minute shipments pop up all the time, but the more lead time you can provide the carriers and providers you work with, the better off you’ll all be.

With sufficient lead time, carriers are able to schedule their operations more efficiently or even find backhauls or headhauls to help defray the cost of moving your freight. Extra lead time will also give brokers more time to source options for you, and you’ll likely benefit by paying less if you can give them this time.

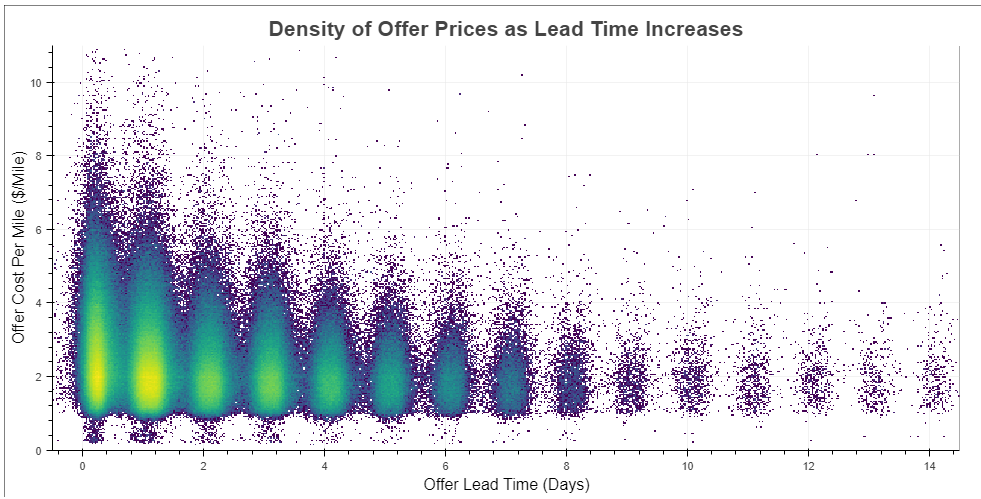

Want to see proof?

In the figure above of real spot truckload offers made by carriers in the Coyote network, the closer shippers inched toward the ship date, the higher the spot offers trend.

Our data shows that given at least 48 hours of lead time, we’re able to secure less expensive capacity for shippers.

So for carriers, more lead time means fewer headaches planning and while on the road. And for you, it means lower rates with higher service. Win-win.

Pay your carriers quickly (and accurately).

Did you know that the majority of the truckload industry is comprised of small and mid-size carriers? In fact, according to the American Trucking Association, there are over 1.1 million for-hire common carriers in the U.S., and of those, 96% operate fewer than 20 trucks.

Many of these carriers don’t have access to a lot of financing, which means value shippers who pay them quickly and accurately very highly.

In our original research study on logistics KPIs, we asked carriers how quickly they expect to get paid for loads they move. 94% of those who responded said they expect payment within 30 days, while 61% believe that within a week or less should be the standard.

We also asked carriers if they are being fairly compensated for accessorials that arise when hauling freight. 34% of those who responded said that at least some of the time they are not.

Because so many of these trucking companies operate lean, fronting the money for those types of charges and waiting to be reimbursed can make or break them.

If your payment terms are longer than 30 days, talk to your accounts payable team about the flexibility to offer faster, even same-day payment terms, when appropriate.

Invest in your data.

There is more logistics data available today than ever before and successful shippers are making it a priority to invest heavily in collecting, analyzing and storing proprietary data.

If you haven’t made this investment yet, the first step you need to take is to centralize your data with a proper transportation management system (TMS). The right TMS will help you eliminate mistake-prone manual data entry tasks and get a holistic view of your supply chain.

This in turn will let you set well-reasoned procurement and operations strategy for your company and help you improve the lead time you can give your providers.

All of this proprietary data will not only help you and your company ship more efficiently, but also allow you to work smarter alongside carriers.

With clean and comprehensive data to analyze, you can identify underperforming facilities, chokepoints in your network, appointment scheduling best practices and much more — and carriers prefer to work with shippers whose internal operations run as smoothly as possible.

Use data to keep score of your carriers.

Can you imagine watching a baseball game for three hours and reaching the end still not knowing for sure if your team won?

Sure, you had a great time and it seemed like your team performed well. But without a recorded score and confirmed winner, you’re left unsure who came out on top and what the outlook is for your team to make it to the World Series at the end of the season.

Carrier scorecards are just as important to your supply chain as the center field scoreboard is to a baseball game. They use your supply chain data to tell you which carriers are performing at the top of their game, which ones could be performing better and what KPIs (on-time pick-up and delivery, primary tender acceptance, etc.) they should focus on improving.

Successful shippers know that the more transparent you can be with your needs, the more likely you are to build strong relationships with your carriers. Making sure you know and communicate what KPIs are most important to you will help all parties align their priorities, and ultimately no one will be surprised when you do get together to discuss these scores.

With proper data and scorecarding, carriers can always know where they stand and both parties can operate as smoothly and as successfully together as possible together

Treat carriers like core business partners.

To continue the baseball analogy — there is something to be said for the importance of being a team player. It doesn’t matter how good of a player you are, if you don’t work well with your teammates then you’ll never make it far.

As with most industries, teamwork and relationships really matter in logistics, especially when it comes to working well with drivers and dispatchers across the freight market. Carriers, especially smaller ones, place a lot of importance on personal relationships, which are vital for keeping the cash flowing to their businesses.

One of the best ways for shippers to achieve relative consistency throughout the ups and downs of the U.S. truckload market’s cycles is to build and nurture stable, long-term relationships with core carriers, rooted in mutual trust and respect.

Decide who you want to do business with and learn each other’s networks, pain points, business needs and more — all the good and the bad.

At the end of the day, shippers of choice are ones that know that they’re not alone in this journey. The more you can work to develop real relationships with worthy carriers, the better off in the long term you and your company will be.

Shippers of Choice Don’t:

Have long load or unload times.

In today’s fast-paced, technology-driven world, no one likes to wait. For anything. We’ve used to having food delivered to our front door at the tap of a button. Almost every convenience we can think of is available to us with virtually no wait.

But what if it wasn’t just convenience that depended on this speed and efficiency — it was paycheck? Waiting would not just be inconvenient, but almost inexcusable.

In a survey of facility reviews by over 3,000 carriers in the Coyote network, 51% of 1-star ratings (the lowest rating possible) were caused at least in part by long load or unload times.

For both carriers and shippers, time is money, and drivers want to get in and out of your facility as quickly and efficiently as possible. Ensure your check-in process is quick, documented and that the documentation accurately reflects what a driver will experience when they arrive on the premise.

Drivers do not have much flexibility in recording their hours of service in a post-ELD landscape; as a result, they are much pickier about how they spend their tightly monitored time.

By building — and honoring — a reputation for short unload and loading times, you are positioning yourself as a top-quality shipper to carriers across the marketplace.

Skimp on facility amenities (or politeness!).

It may seem silly to even list this, but a lack of bathrooms and other basic amenities can be a deal-breaker for carriers. No one wants to be on the road for hours, days or even weeks at a time without a warm welcome when they reach their destination.

Providing access to basic amenities — even just access to clean bathrooms — goes a long way in the eyes of a carrier. Life on the road isn’t easy and preferred shipper facilities can include on-site overnight parking, bathrooms, a driver’s lounge, vending machines and access to free wi-fi.

In that same facility review survey, 23% of 5-star ratings indicated that staff at receiving facilities were friendly, polite and professional. A smile, clear instructions and a simple “thank you” are always appreciated and are easy policies to implement on your road to becoming a shipper of choice.

Have an inflexible appointment scheduling process.

We know there are many factors that go into scheduling a delivery or pick-up appointment. The more flexible you can be with your appointment scheduling, the more carriers will prefer to pick up your shipments.

Open appointments are especially preferred — having a window to get loaded or unloaded as opposed to a strict appointment is ideal for carriers.

With a little flexibility on your end, you can position yourself to consistently access a greater capacity pool of carriers.

Ignore your accessorial spend.

Trucking accessorials — detention, truck/equipment order not used, layovers, etc. — are mostly avoidable expenses that come directly out of your budget. While you’ll never eliminate them completely, it’s crucial to keep an eye on how much you’re actually spending on these fees.

Our proprietary data reveals that if more than .06% of your total carrier spend goes to paying these accessorials, you are potentially taking up too much driver time.

And in a tight market, carriers may choose to prioritize more efficient facilities. That’s why it’s so important to have a proper TMS in place and a strong idea of the KPIs you’re tracking — you can watch how much you’re spending over time and take action going forward when that spend indicates that your operations are inefficient.

Do You Have What It Takes to Be a Shipper of Choice?

Becoming a preferred shipper in a tight market — or in any market — is a continuous process that takes strategy, vision, commitment, resources and time.

By implementing any of these do’s (and avoiding those dont’s), you can make yourself stand out with carriers of all sizes.

And the more you can optimize your supply chain and operational processes now, the better prepared you will be to move goods faster, operate leaner and increase your standing with carriers in the future.

Are you ready to be a shipper of choice today? Find out more about the dedicated capacity options you can access when you ship with us.