Supply Chain Outsourcing for the Win: How 500 Shippers Use 3PLs

To outsource or build in-house?

Choosing the right strategy will help you out-ship your competition, while the wrong one will lead to lost customers and a bloated budget.

If you’re looking for a little guidance as you seek the right blend of in-house capabilities and outsourced providers in your supply chain, start by using your peers.

In this original research study, you can get data-backed insights from over 500 shippers (see full respondent demographics).

Learn how and what they outsource to third-party logistics providers (3PLs) across their supply chain management, including procurement, transportation and warehousing operations.

Research Study Table of Contents

Use links to jump to sections

- The C-Suite Takes Notice

- Trends in Supply Chain Outsourcing

- Outsourcing vs. In-House: What Shippers Think Works Best

- Choosing an Outsourced Provider: What Shippers Look For

- Using Supply Chain Consultants

- Using Third-Party Supply Chain Technology

- Recap: 10 Key Takeaways

- Respondent Demographic

Rather read this as a PDF?

You can download a PDF version of the study, as well as formatted PowerPoint slides with the study graphs for your next presentation.

Download Study PDF & PowerPoint Slides

The C-Suite Takes Notice:

Executives Invest in Supply Chain

If the last two years taught companies anything, it was how important a high-performing supply chain really is.

And the C-suite has taken the lesson to heart.

Companies are now treating supply chain with the same deference as finance and sales.

Many companies are even giving supply chain its own seat in the boardroom — 29% of shippers have a Chief Supply Chain Officer (CSCO), and that figure jumps to 36% for companies with over $800M in annual revenue.

Driven by the era of fast-and-free delivery, and supercharged by a global pandemic, executives have had to become increasingly logistics-savvy.

They’ve also had to back it up with more resources.

According to the 505 supply chain decision makers in our study, a vast majority agree that their corporate leadership has both a good understanding of how their supply chain works, and is investing in improving supply chain capabilities.

You can download these graphs as PowerPoint slides for your next presentation.

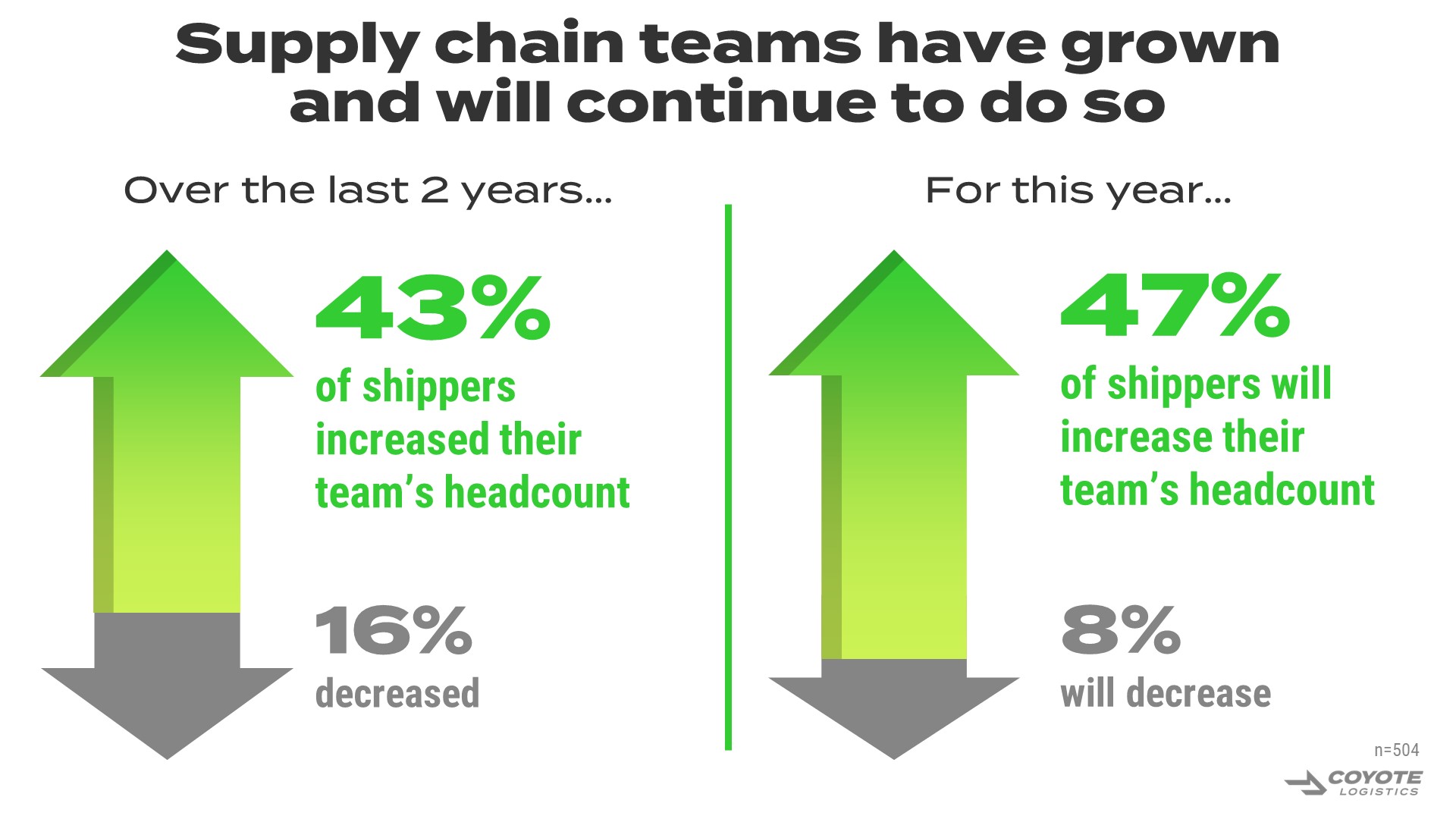

One of the ways companies are investing is through growing their internal people expertise.

Over the past two years, 43% of shippers grew their supply chain team’s headcount, compared to only 16% who decreased.

And despite a shaky economic outlook, that trend looks to continue, with 47% of shippers planning to grow supply chain headcount again this year, compared to only 8% who are downsizing.

But building internal capabilities is only part of the equation — shippers are also investing heavily with their third-party providers.

“Supply chain outsourcing is an art that needs to be mastered.”

VP of Logistics

$250 million – $799 million CPG Shipper

Trends in Supply Chain Outsourcing

In the midst of historic volatility, shippers turned to their 3PLs for help. The ready access to scalability, capacity and expertise proved to be a reliable way to stabilize operations.

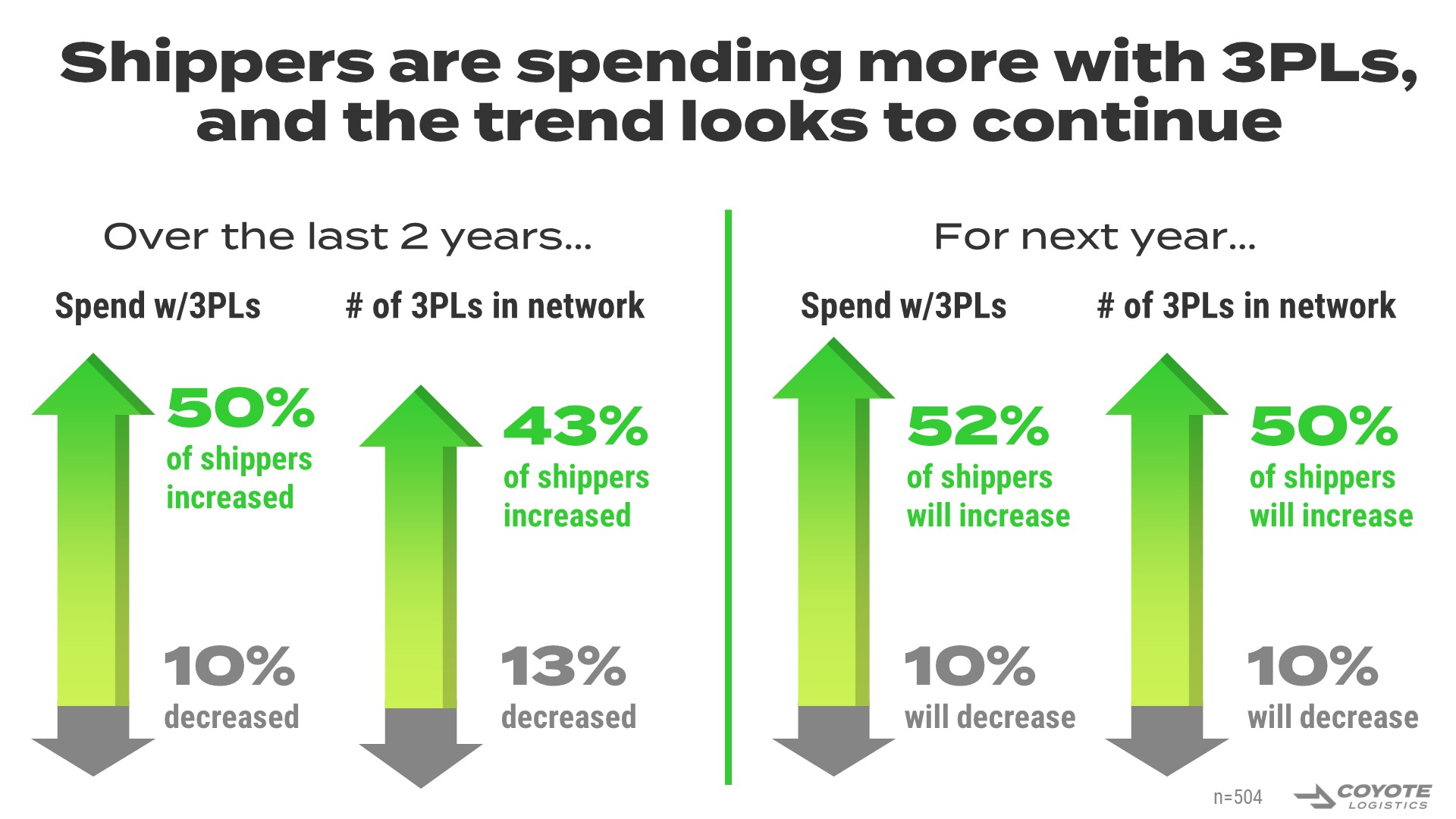

Over the past two years, 50% of shippers increased their spend with outsourced providers, compared to only 12% that decreased spend.

Not only did shippers spend more overall, but they did so with more 3PLs — 43% of shippers expanded their provider base, compared to only 13% who decreased.

And while freight markets are in a very different place now, shippers are doubling down on their commitment to outsourcing.

Over half of respondents plan on increasing their spend with 3PLs again this year — a 2% jump compared to the last two years.

A majority also plan on increasing the number of 3PLs in their network, up 7% compared to the last two years.

You can download these graphs as PowerPoint slides for your next presentation.

Though many shippers are increasing their investment in both their internal teams and outsourced providers, knowing which strategy to apply in each situation is not a straightforward choice.

Outsourcing vs. In-House:

What Shippers Think Works Best For Every

Area of Supply Chain Management

81% of shippers are investing to improve their supply chain, but that doesn’t just mean hiring more people.

While building out internal capabilities is certainly part of the process, companies cannot (and should not) do it all by themselves.

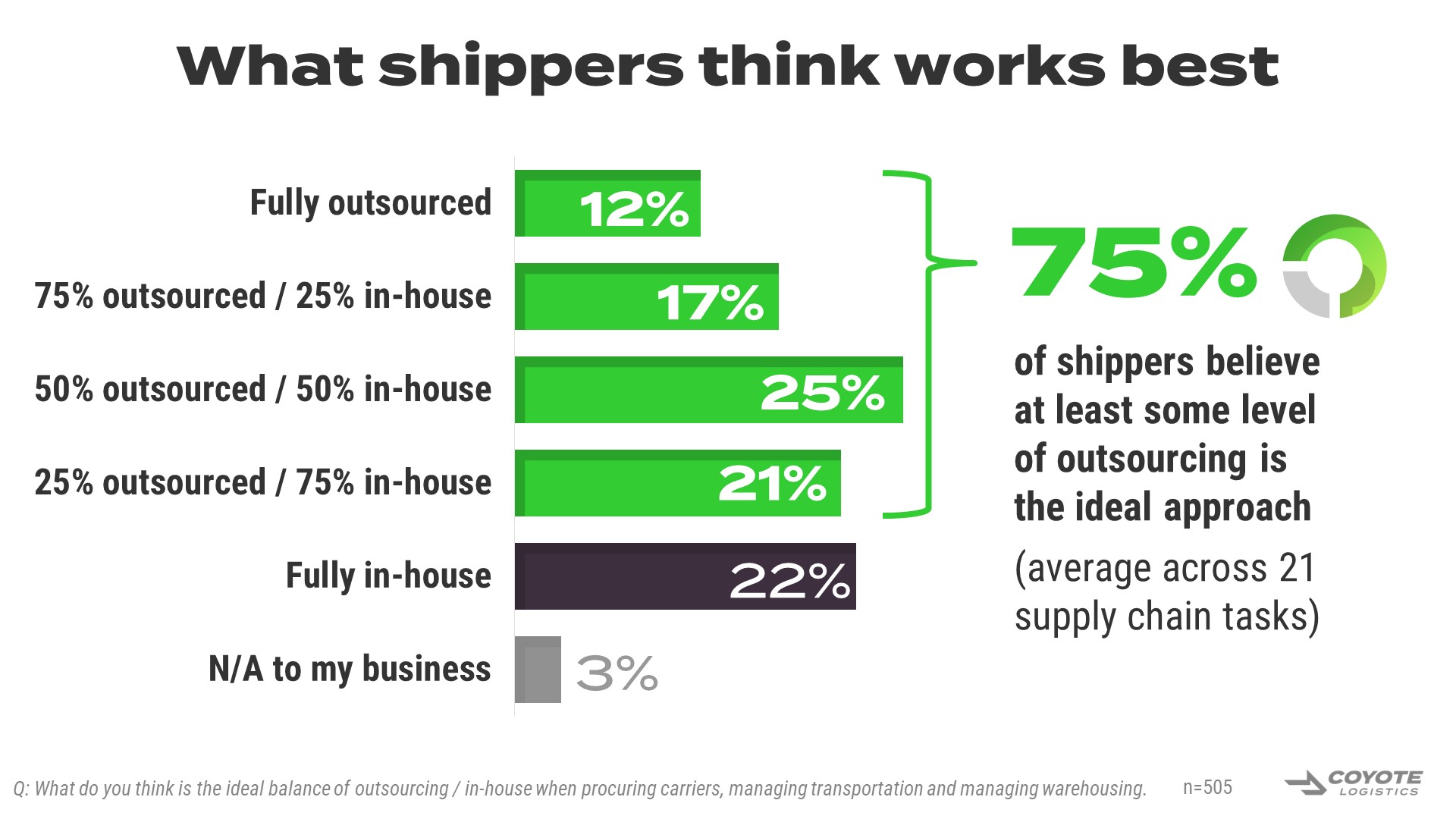

Looking at 21 different areas of supply chain management, there wasn’t a single area where a majority of shippers thought fully in-house was the ideal approach (the closest was only at 36%).

Every shipper relies on a myriad of third-party providers to manage inventory, fulfill orders and transport freight.

On average across all areas, 75% of shippers think at least some level of outsourcing is ideal.

“Supply chain outsourcing — when done right — can benefit a company immensely.”

Logistics Manager

$2 billion – $5 billion Manufacturing Shipper

It’s clear that the vast majority don’t think it’s a question of if they’re going to outsource, but how.

Before we dig into how shippers are outsourcing, let’s first touch on the why.

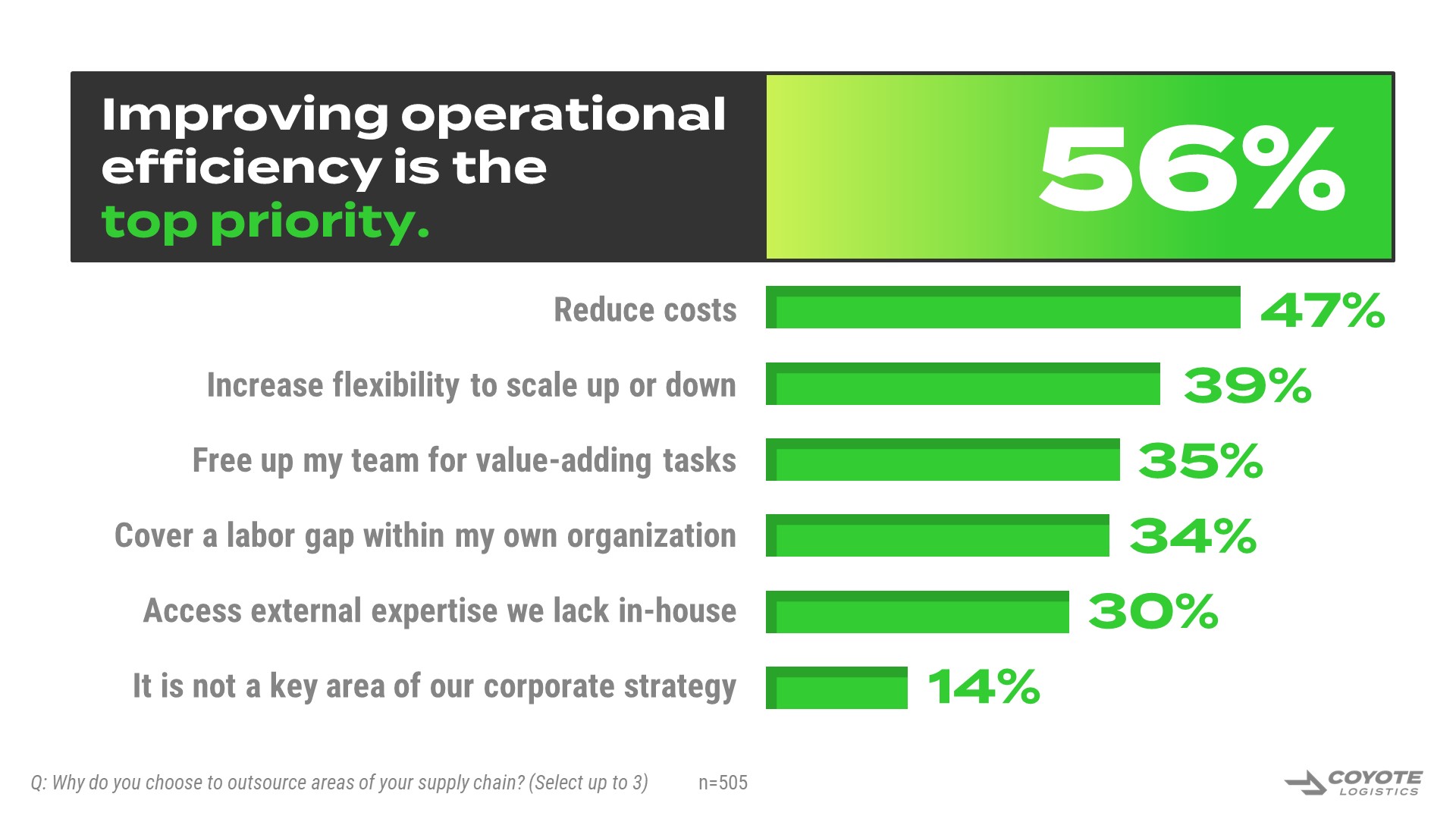

Why Shippers Outsource

The rationale for outsourcing may seem pretty straightforward: “Either a third party can do this better than us or cheaper than us (maybe both).”

However, shippers often have multiple reasons driving them to seek external help, and those reasons change depending on their unique supply chain requirements.

This means different priorities, and therefore, a different approach to their outsourcing strategy.

When asked why they outsource, there was only one reason (increase operational efficiency) where a majority of shippers agreed.

At the very least, supply chain leaders think working with 3PLs gives them a little boost when explaining their budget — 69% agree that working with an outsourced provider makes it easier to validate decisions to company leadership.

“Having an outsourced model for our supply chain makes sense for so many reasons.

We can’t staff enough labor to cover our shipping needs, and with so much uncertainty, having the assets needed to handle internally is a bit risky and very expensive.

Outsourcing provides much more flexibility and allows our team members to focus on other areas.”

Director of Supply Chain

$2 billion – $5 billion Food & Beverage Shipper

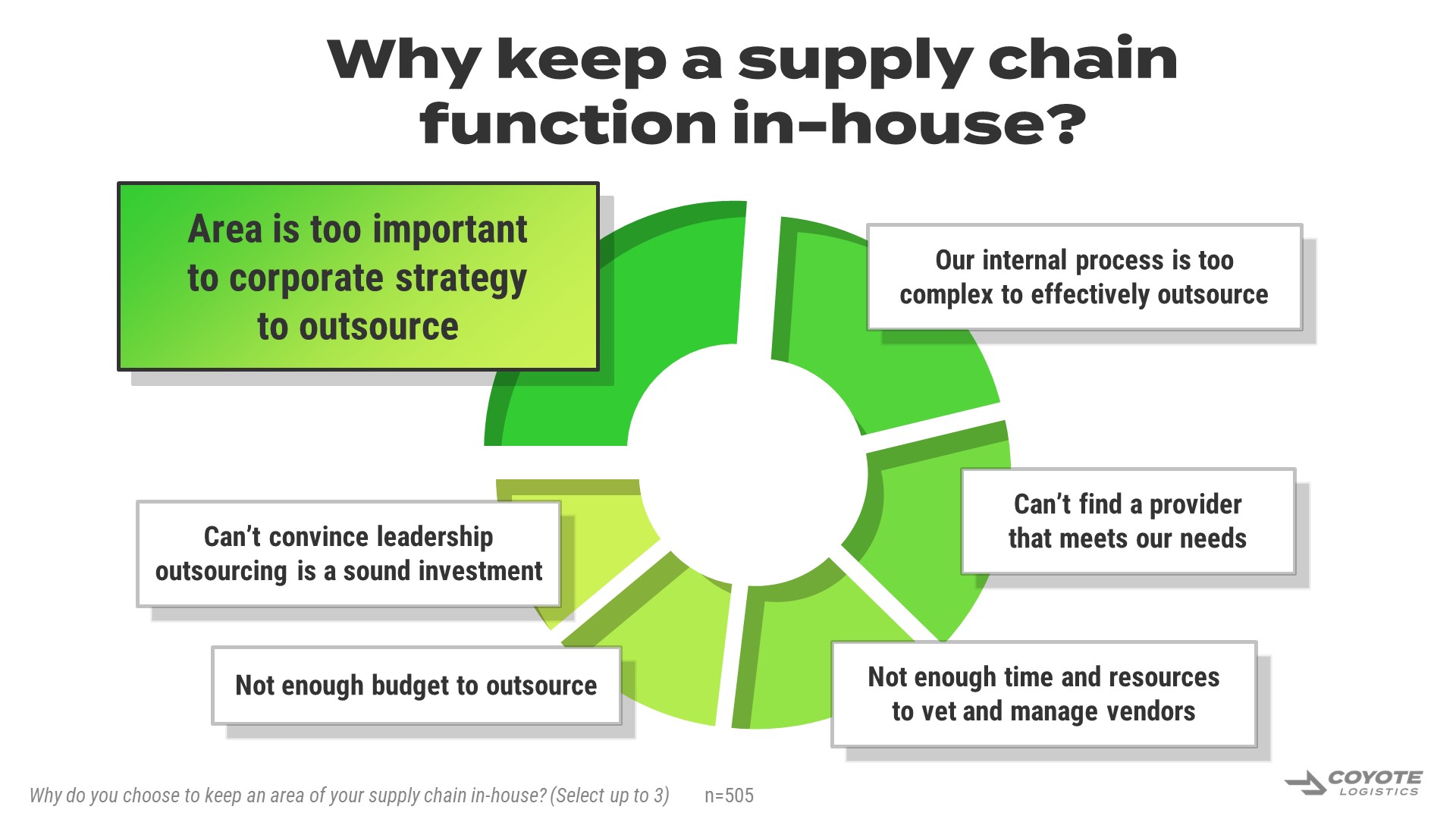

Why Shippers Keep Things In-House

Shippers outsource for a variety of reasons — the same can be said for the opposite strategy.

When asked why they keep something in-house, there was only one reason (area is too important to corporate strategy to outsource) where a majority of respondents agreed.

There was no clear consensus, but instead a distribution across several possibilities.

“I choose to outsource elements of our supply chain depending on availability and cost. I still normally run ~50% in-house since I prefer redundancy, just in case.”

Executive

$2 billion – $5 billion Retail Shipper

To bring clarity into exactly how shippers are blending in-house operations with outsourced providers, we asked them what they think the ideal approach is across carrier procurement, transportation management, warehousing, strategy and technology.

Outsourcing vs. In-House:

Carrier Procurement

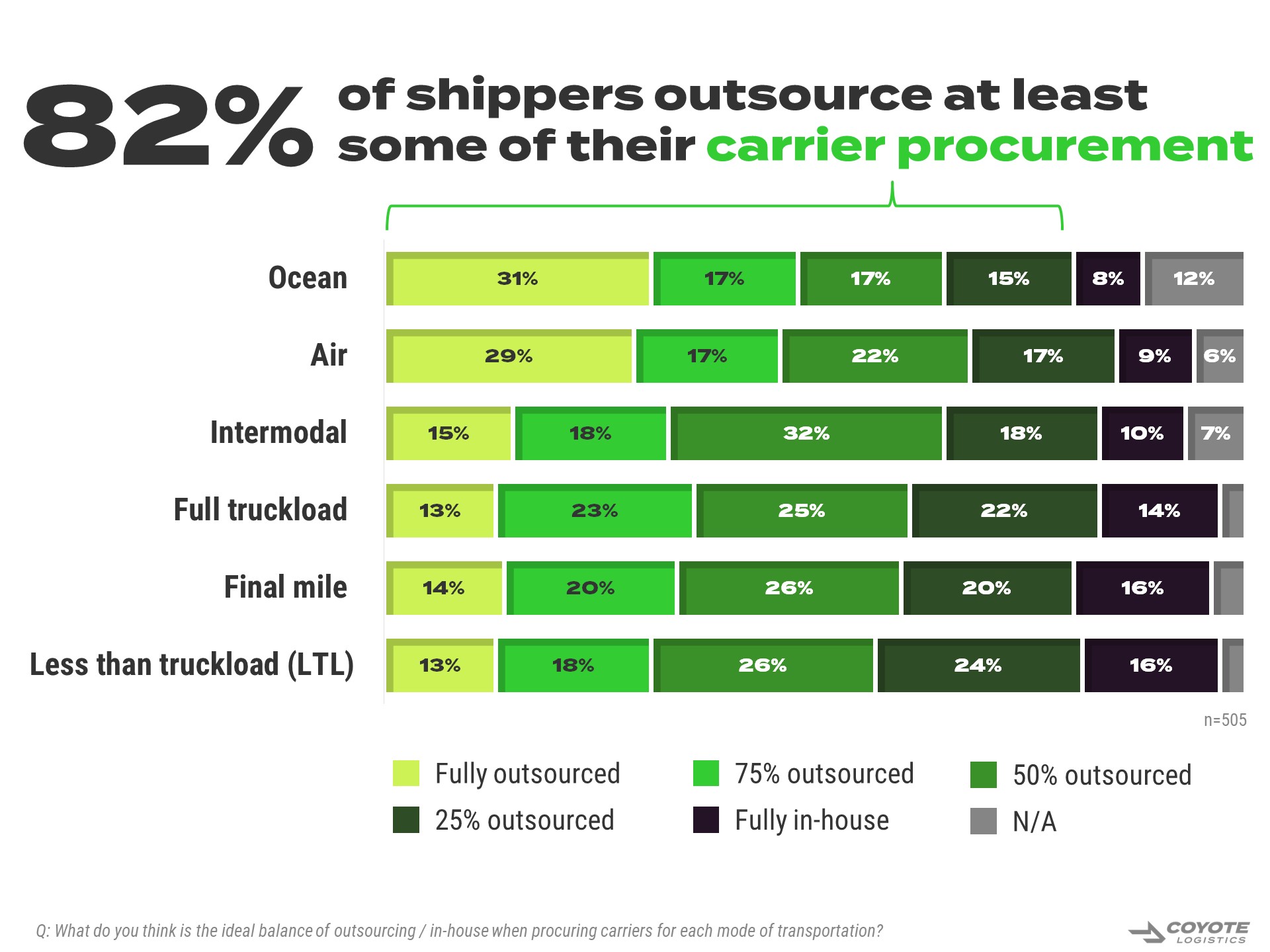

If there was one area where shippers value the flexibility and reach of a 3PL, it’s sourcing capacity, AKA carrier procurement.

Considering every area of supply chain management, it was their most likely area to outsource.

Looking at the average across all modes, 82% of shippers rely on third-party providers to procure capacity for at least some of their freight, with 38% using 3PLs for a majority of their shipments.

Though most shippers make ample use of 3PLs for procurement, few take an all-or-nothing approach.

The most common strategy was actually an even split between in-house and outsourced — only 19% of shippers (averaged across all modes) think fully outsourced carrier procurement is ideal, and only 12% think fully in-house is ideal.

You can download these graphs as PowerPoint slides for your next presentation.

Looking at the most common approach by individual mode, shippers are most likely to fully outsource their international shipments to a freight forwarder (29% of shippers for air, 31% for ocean).

The added complexity from customs and foreign carrier markets makes the simplicity of outsourcing especially appealing.

A 50/50 split was the most common ideal approach for truckload (25%), LTL (26%), final mile (26%) and intermodal (32%).

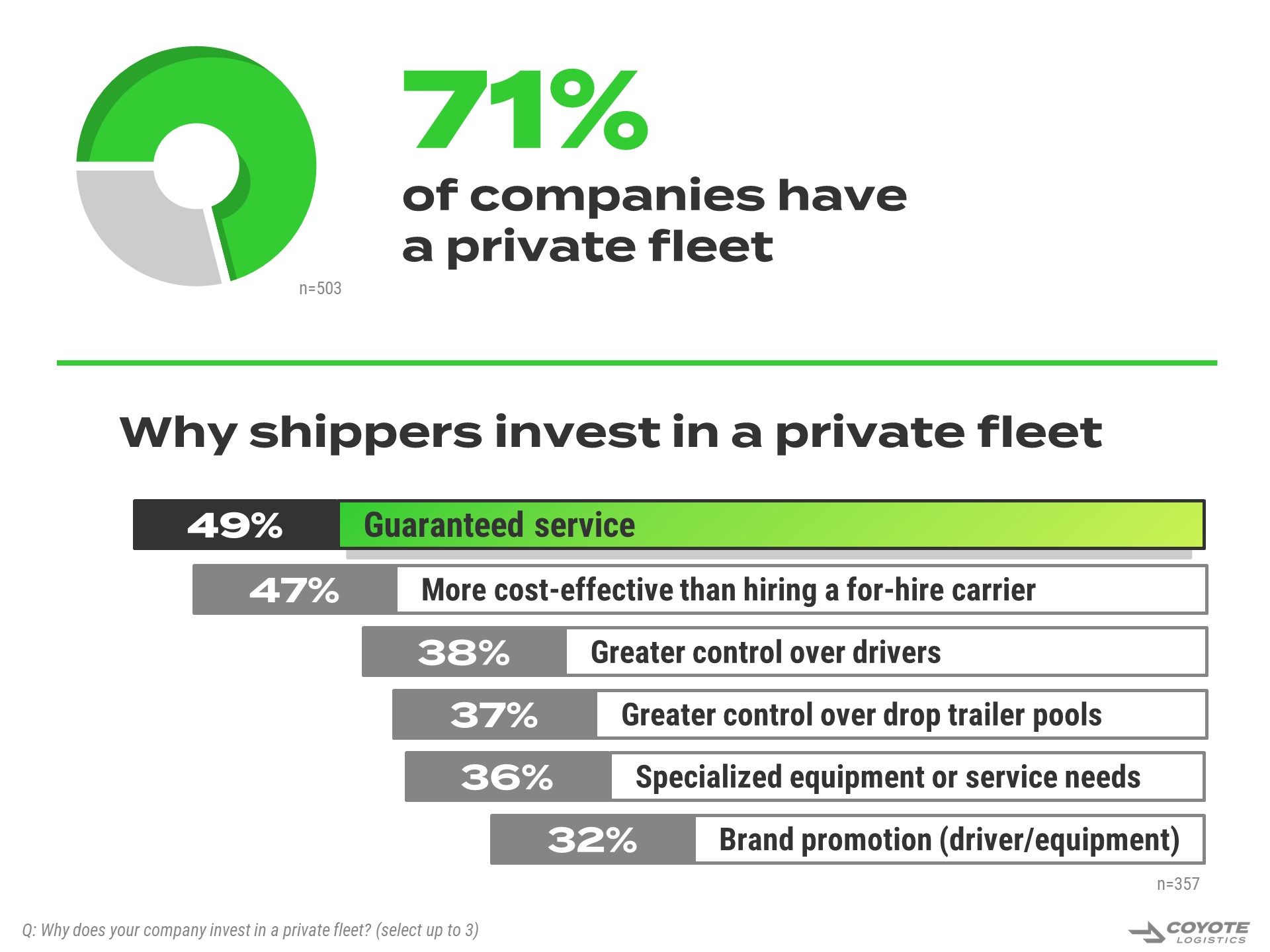

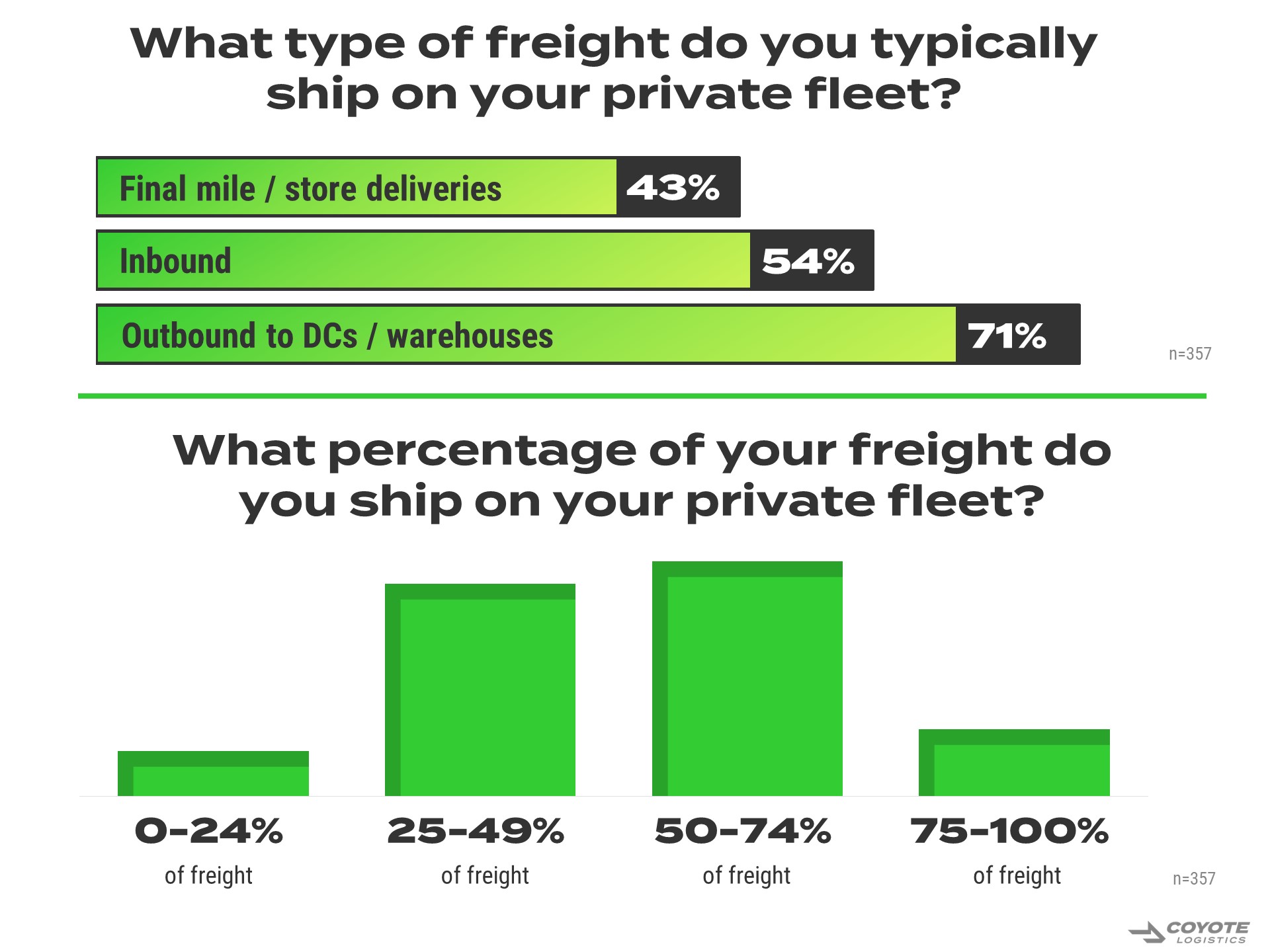

Keeping Capacity In-House With a Private Fleet

The best way to avoid outsourcing carrier procurement is to not have to procure any carriers at all.

Having a private fleet is perhaps the quintessential in-house supply chain function, and most shippers in this study (71%) are making use of it.

Though a majority have a private fleet, there is no consensus as to why shippers choose to invest.

Only 17% separates the top reason (guaranteed service at 49% of shippers) from the bottom (brand promotion at 32%).

Shippers use their private fleets for all types of trucking shipments, but the most common was outbound shipments to distribution centers (71%).

But shippers do not expect their fleet to do it all — only 12% of shippers are using their fleet for over 75% of their freight.

Instead, most take a blended approach, relying on third parties to move a good chunk of their shipments.

Even shippers that have private fleets will often rely on 3PLs to help them with a backhaul program to reduce empty miles.

You can download these graphs as PowerPoint slides for your next presentation.

Outsourcing vs. In-House:

Other Areas of Transportation Management

Shippers rely on third-party providers for every aspect of transportation management, not just carrier procurement.

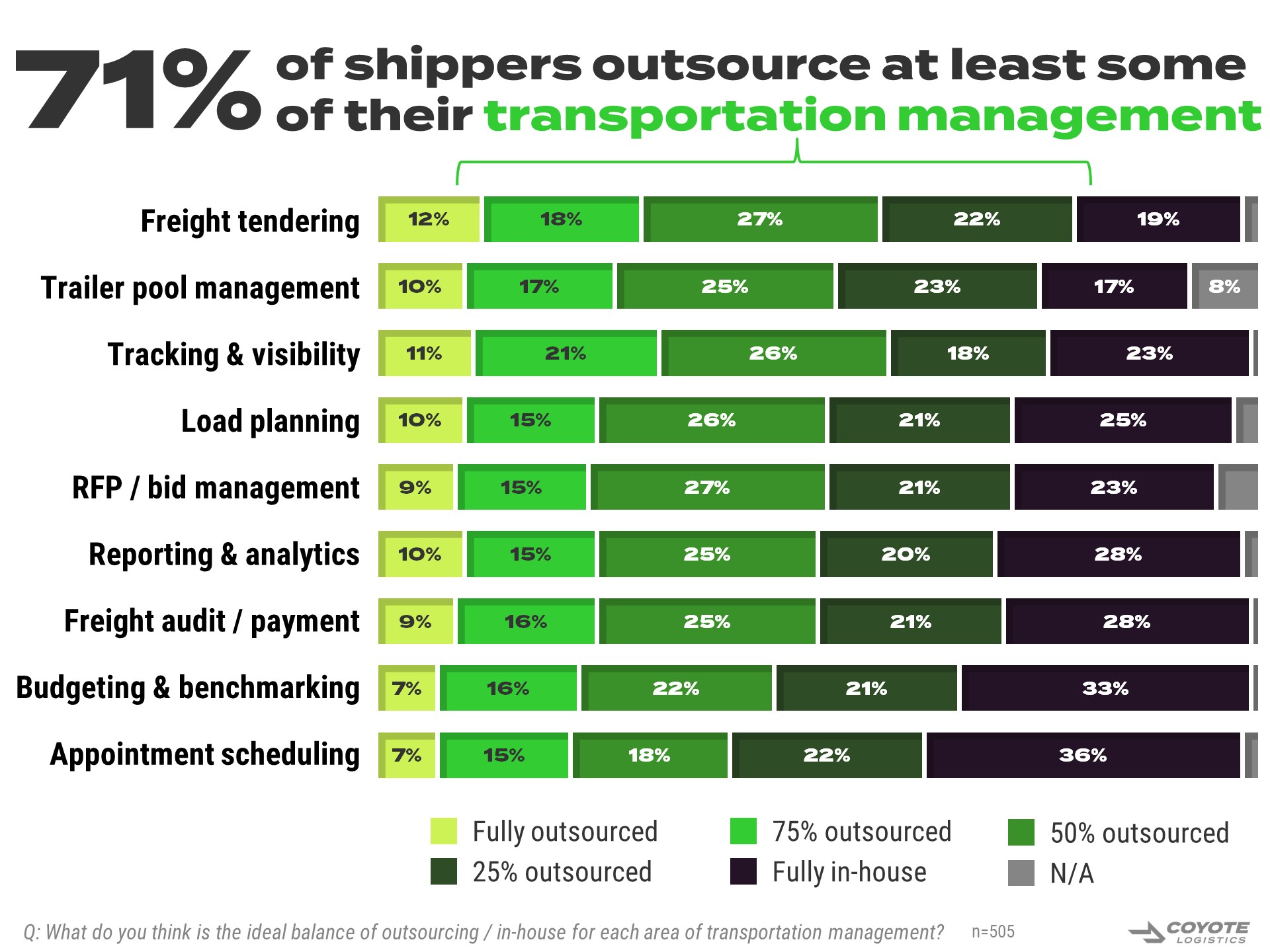

Looking at an average of nine other areas of transportation management, 71% of shippers think at least some level of third-party support is ideal (slightly less than the 81% for carrier procurement alone).

While fully in-house was the most common approach when averaging across all areas, it was far from a clear favorite — 26% of shippers thought fully in-house was ideal, with a 50/50 split coming in a close second at 25%.

In fact, there was not a single area where a majority of shippers agreed on the best approach, with the closest being appointment scheduling at 36% fully in-house.

Looking at individual areas of operation, fully in-house was the most common approach for appointment scheduling (36% of shippers), budgeting & benchmarking (33%), freight audit / payments (28%), and reporting & analytics (28%).

Many viewed freight tracking & visibility and freight tendering as prime candidates for outsourcing.

Outsourcing vs. In-House:

Warehouse Management

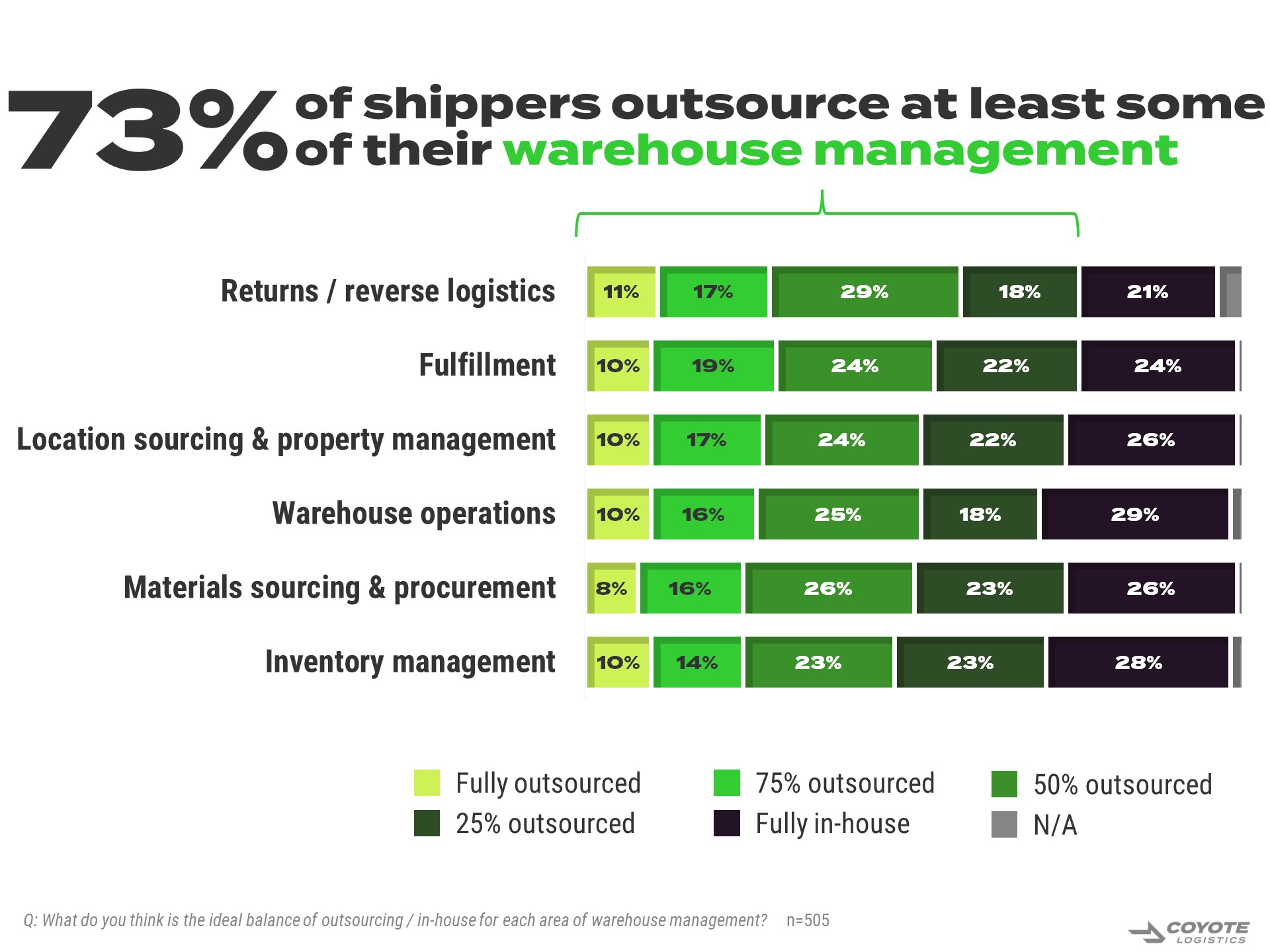

Warehousing is another essential component of supply chain management and, just like transportation management, shippers rely on a blend of third-party support and in-house expertise.

When averaging the ideal approach across six areas of warehouse operations, the breakdown was almost identical to transportation management, with fully in-house as the most common approach (26% of shippers) followed closely by a 50/50 split between outsourced providers and in-house (25%).

Looking at individual areas of warehouse management, shippers were, unsurprisingly, more likely to keep operations that happen inside the warehouse fully in-house (inventory management, warehouse operations, warehouse location sourcing, and property management).

They were more likely to bring in some third-party assistance with operations that involve freight movement outside of the warehouse (returns / reverse logistics, materials sourcing & procurement, and fulfillment).

“During our significant seasonal increase of business, outsourcing some activities is necessary to handle fulfillment. We have been very fortunate to find great partners for this!”

VP of Supply Chain

$250 million – $799 million Retail Shipper

Choosing an Outsourced Provider:

What Shippers Look For in Their 3PLs

Deciding to outsource is one thing.

Finding the right third-party provider is another.

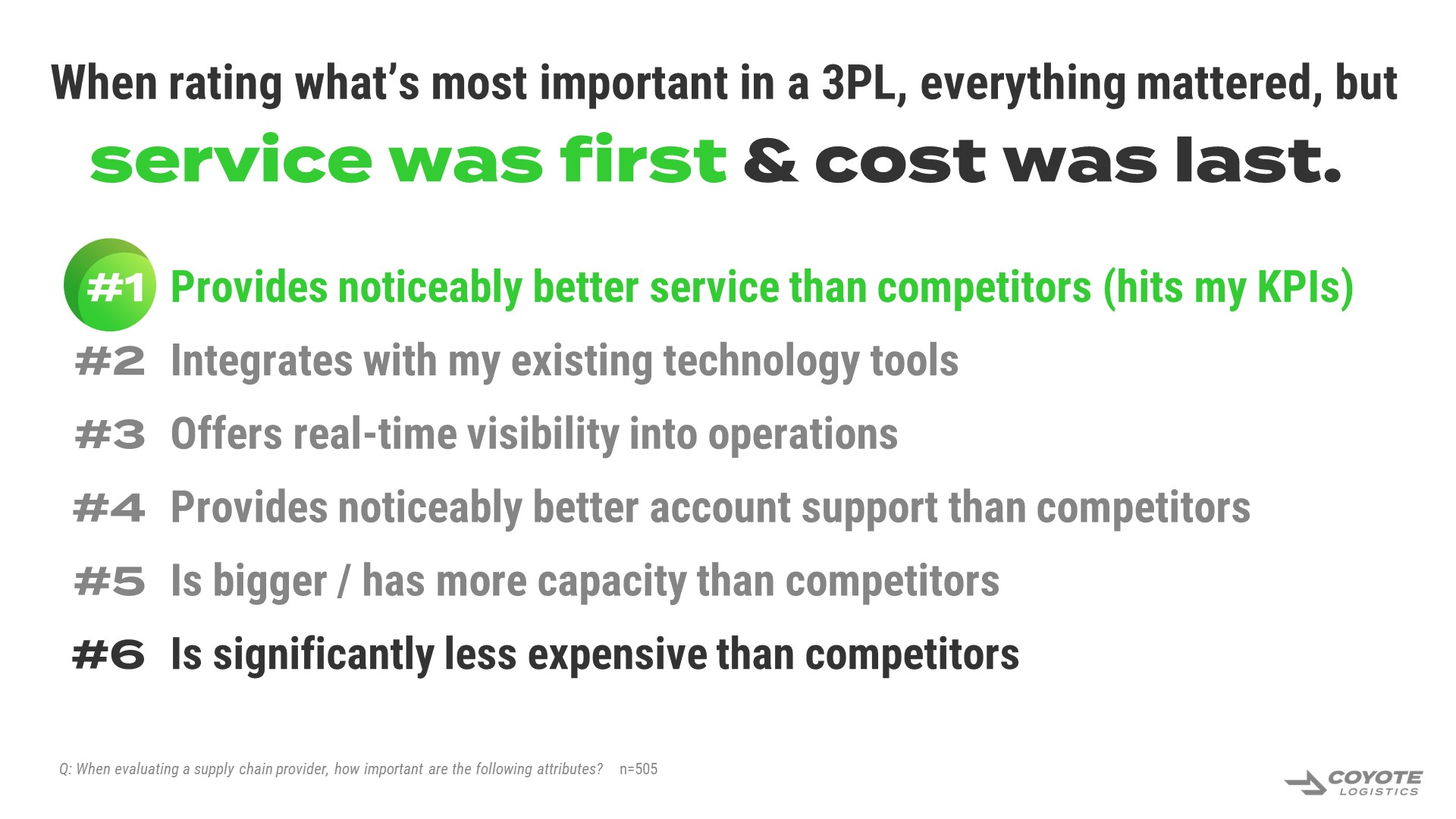

We asked shippers to rate the importance of different attributes when choosing their 3PLs.

Unsurprisingly, shippers want a provider that has it all (the lowest-rated attribute was at 70%), but some features were ahead of the rest.

As we found in our supply chain KPI research study, when it comes down to cost vs. service, service wins.

82% of shippers agreed that provides noticeably better service than competitors (hits my KPIs) was important, making it the top consideration factor; is significantly less expensive than competitors (70% of shippers) was the bottom.

Of course, cost is still a critical factor, but most shippers start their 3PL search with a focus on value and reliability, not a steep discount.

Outsourcing also has to be seamless — the collection and communication of data are major consideration factors, with offers real-time visibility into operations and integrates with my existing technology tools as the second and fourth most important criteria, respectively.

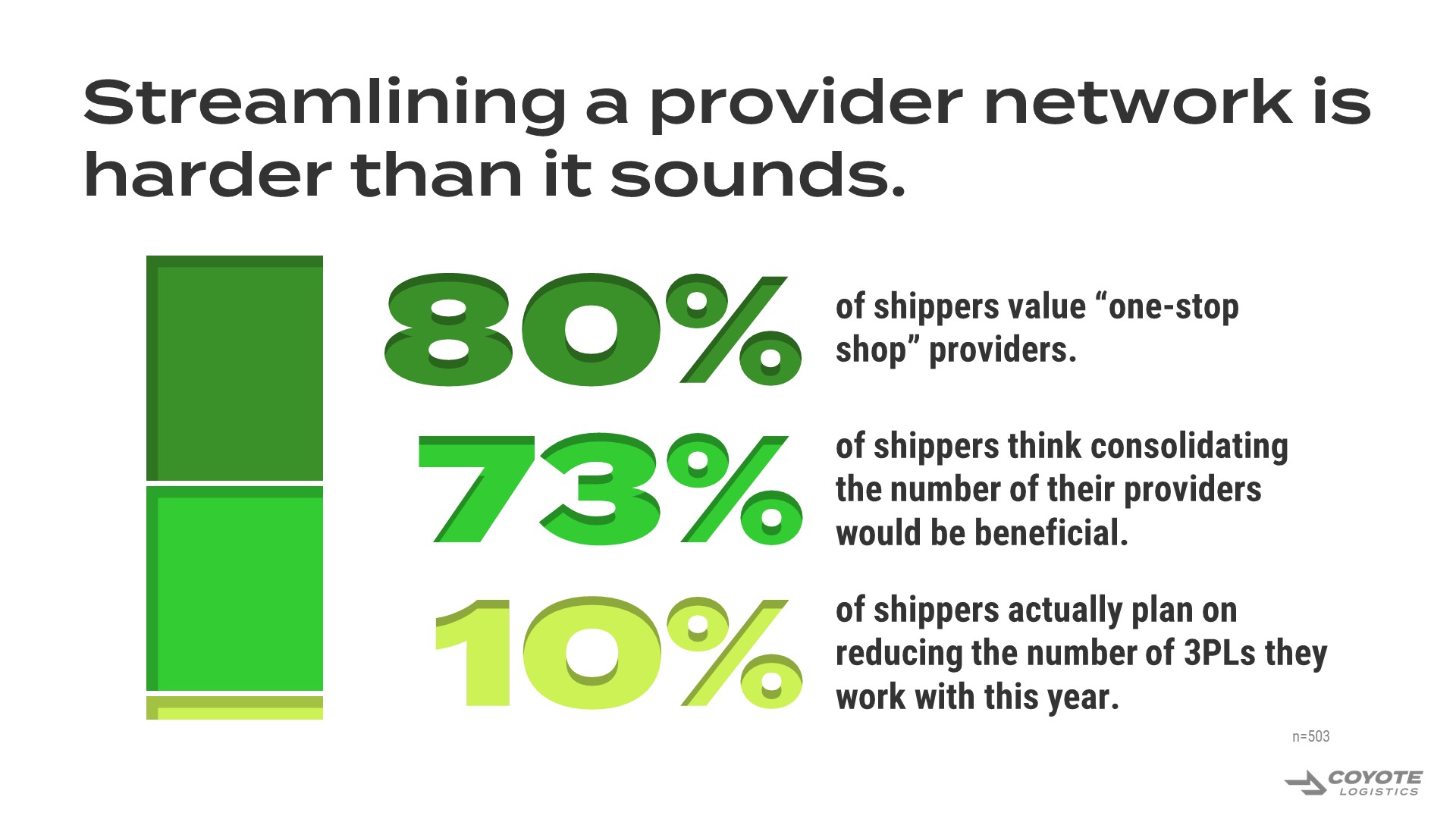

Shippers are also looking to streamline their provider base — 80% of shippers agree that “one-stop shop” providers that can perform multiple functions are valuable, and 73% think consolidating the number of third-party providers in their network would be beneficial.

This may, however, be aspirational — 43% of shippers still increased their provider base over the last two years (compared to only 13% who decreased) and 50% plan on increasing it this year (compared to only 10% planning on decreasing).

“I look for an established company with a history of doing good work for other companies.”

VP of Supply Chain

$250 million – $799 million Manufacturing Shipper

As you look to rationalize your own provider base, relying on these insights from your peers can help.

When challenges demand a higher level of support, however, many of your peers have benefitted from working with supply chain consultants.

Using Supply Chain Consultants

No one knows the complexities and intricacies of your supply chain operations as well as you, but a fresh set of eyes can lead to better results.

If you are considering getting some assistance in setting your supply chain strategy, you are in good company.

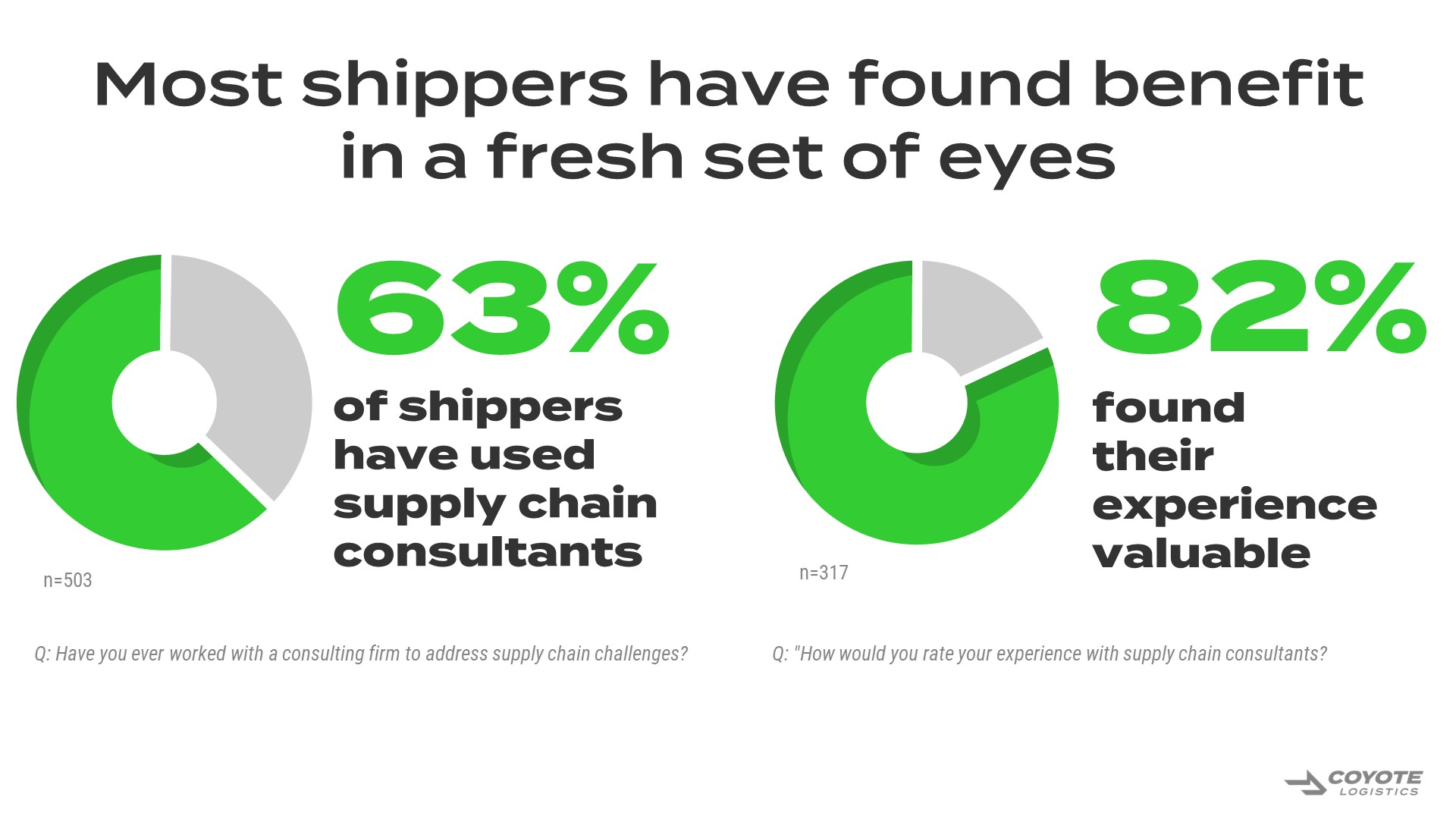

63% of shippers in this study have worked with supply chain consultants, and of those, 82% found the experience valuable.

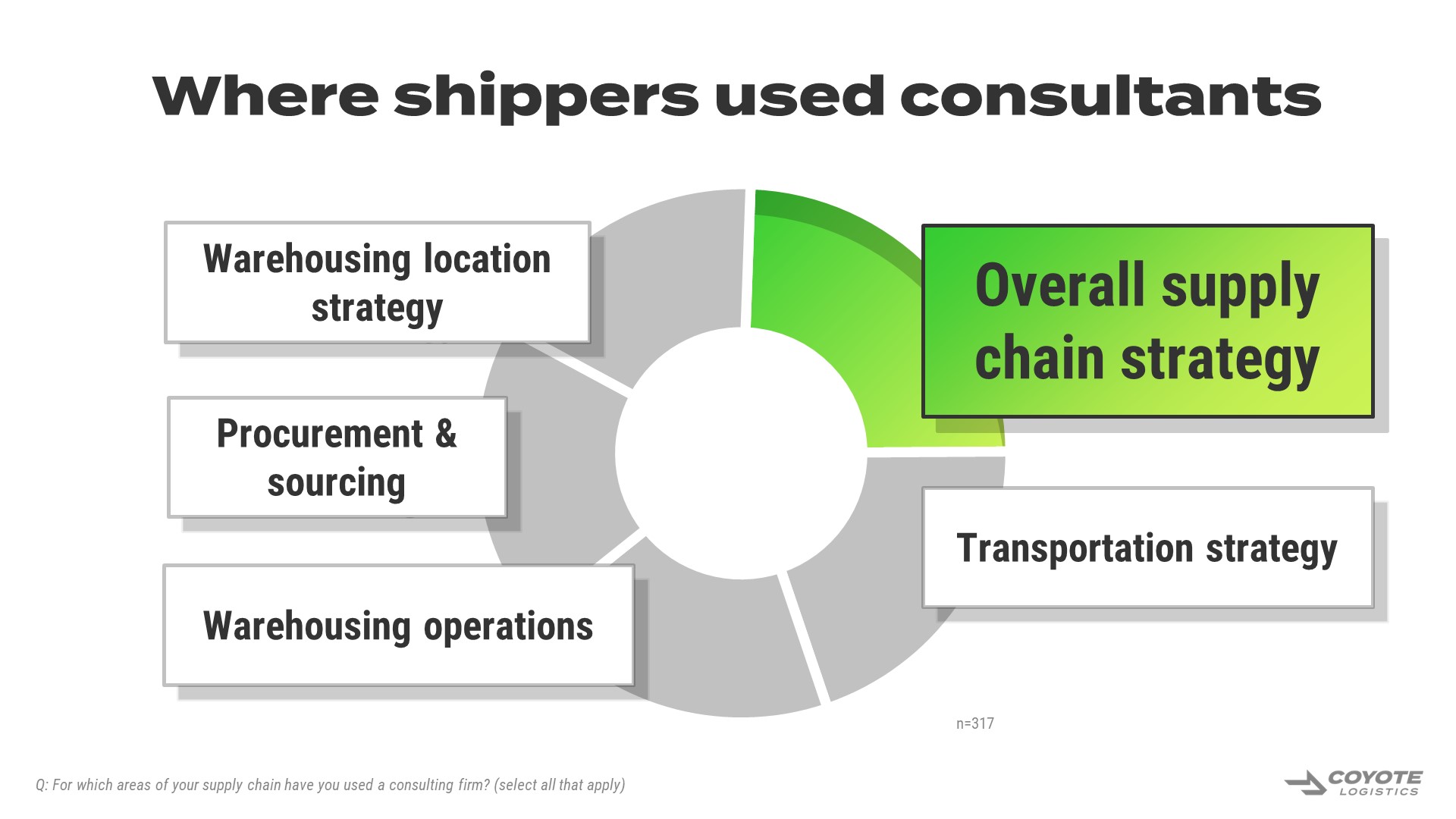

Shippers were most likely to hire consultants for assistance with overall supply chain strategy (55% of shippers) and transportation strategy (45%).

You can download these graphs as PowerPoint slides for your next presentation.

Since 2020, inventory management has been unbelievably complicated due to demand volatility, and a tight labor market has made hiring a headache.

Now that freight markets have started to stabilize, many shippers are looking to become more efficient with their existing properties and people.

When asked where they would like to hire supply chain consultants for this year, 56% said warehousing operations, up 12% from the last two years.

Using Third-Party Supply Chain Technology

Supply chain outsourcing extends beyond physical inventory management and freight shipping — shippers rely on third-party supply chain technology providers, too.

Getting digital help is just as integral as any other element of outsourcing.

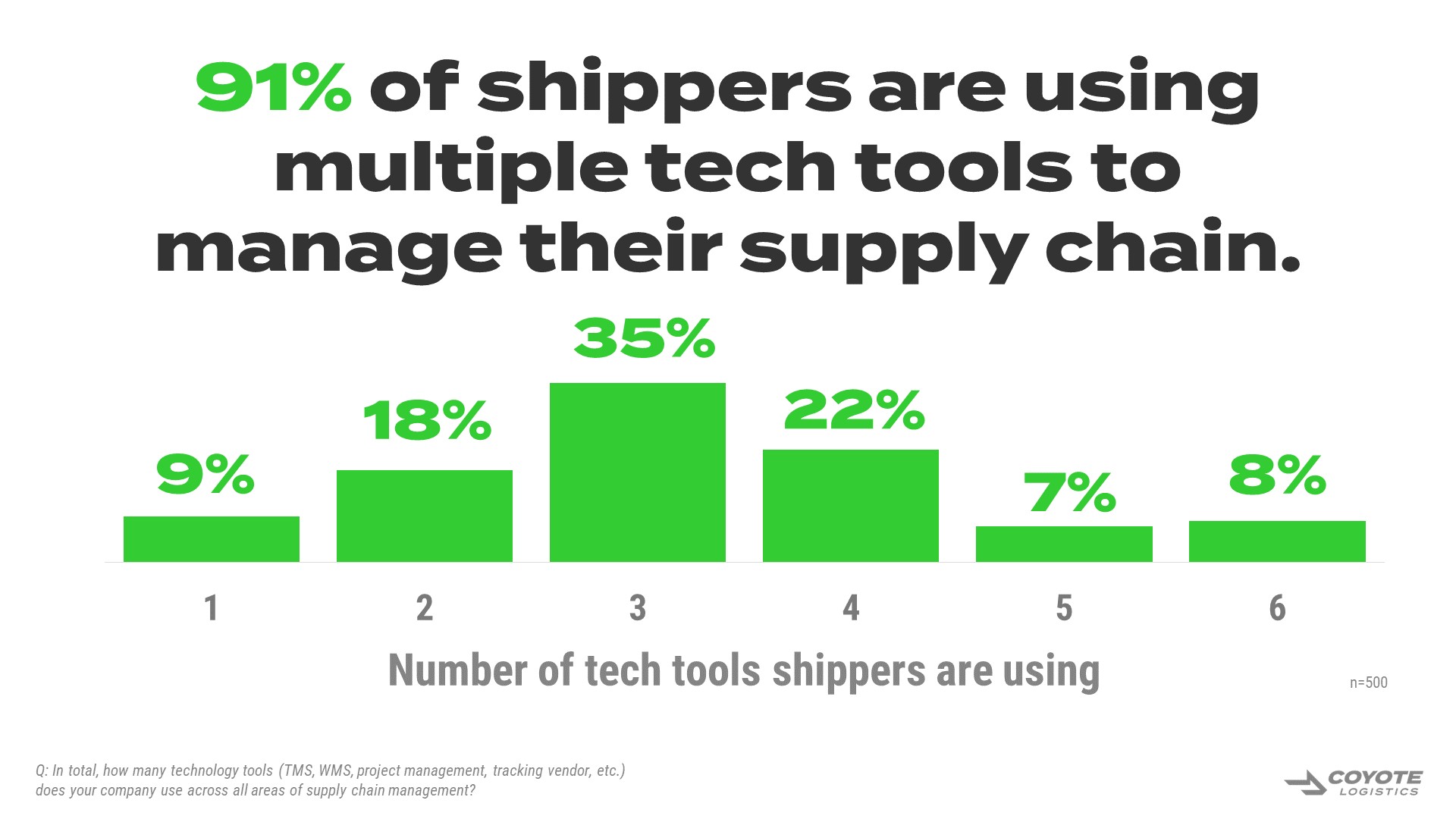

Shippers rely on an average of three different technology tools to manage their supply chain; 37% of shippers are even using four or more.

You can download these graphs as PowerPoint slides for your next presentation.

Though technology increases efficiency in many areas, it creates some of its own problems.

The biggest challenge shippers have with third-party software is integration across all my systems, followed by integration with all my providers, which is why 78% of shippers think integration with existing tools is important when choosing a 3PL.

“Biggest unmet need? We haven’t yet found one system that can integrate all of our providers.”

Executive

$800 million – $2 billion CPG Shipper

Outsourced Supply Chain: 10 Key Takeaways From the Research

No supply chain is an island.

Even the most advanced and self-sufficient shippers rely on third-party providers across multiple areas of their supply chain management.

It’s not a question of if you’ll outsource, but to what degree.

Though every company has its own requirements and priorities for its supply chain, these insights from over 500 of your peers can help guide your decision-making process (or at least validate your strategy to leadership).

In this study, we covered outsourcing trends and approaches in detail, but let’s quickly recap what you learned.

10 Key Takeaways for Supply Chain Leaders

- (Almost) everyone is outsourcing.

When asked for their ideal balance between outsourcing and in-house operations across 21 areas of supply chain management, 75% of shippers think that at least some level of outsourcing is the best approach. - But there is no one right way to do it.

Looking at those same 21 areas, there wasn’t a single one where a majority of shippers agreed on the best approach — the closest was only 36% of respondents. - The C-suite is supply chain savvy (and signing the checks).

79% of shippers think their corporate leadership has a good understanding of how their supply chain works, and 81% believe their corporate leadership is investing in improving supply chain capabilities. - Increasing spend with outsourced providers is…in.

Over the past two years, 50% of shippers increased their spend with third-party providers (only 12% reported a decrease). Looking to this year, 52% expect it to grow again, compared to only 10% who are going to decrease spend with 3PLs. - Private fleets: a very common way to keep it in-house.

71% of shippers have an in-house private fleet, with guaranteed service the most likely reason they invest, and outbound freight to distribution centers the most common use case. Though these shippers rely heavily on their fleets, they still make use of third parties — only 12% use their fleet to haul over 75% of their freight. - It’s not in-house vs. outsourcing, but in-house and outsourcing.

A fully outsourced approach and fully in-house approach are at the ends of a bell curve — for each area of supply chain management, most shippers think the best approach lies in between, preferring a blend of the two. And they’re not mutually exclusive — most shippers think their outsourcing spend and supply chain team headcount will grow this year. - If you’re only going to outsource one thing, make it carrier procurement.

Though shippers outsource to 3PLs across every area of transportation and warehouse management, they rely on them most consistently for air, ocean, truckload, LTL, final mile and intermodal carrier capacity. - You’re not too smart to hire a supply chain consultant.

63% of shippers have worked with a supply chain consultant to help set their strategy, and 82% of those found their experience to be valuable. - Everyone says they want a smaller provider base, but few are doing it.

80% of shippers agree that “one-stop shop” providers are valuable, and 73% think it would be beneficial to consolidate the number of providers in their network. Yet only 10% of shippers are decreasing their outsourced provider count this year, and 50% are even increasing it. - Integrations are important (but hard).

On average, shippers are using three technology tools to manage their supply chain. It’s no surprise that integrations across all my systems and integrations with all my providers were the #1 and #2 challenges, respectively, that shippers are having with their supply chain software. Furthermore, data integration capabilities are a consideration factor for 78% of shippers when choosing a new 3PL.

“Supply chain outsourcing can be a great way for businesses to save money and resources, streamline operations and gain access to valuable expertise and specialized technology.”

Executive

$800 million – $2 billion Automotive Shipper

Need Help Outsourcing a Part of Your Supply Chain?

If you could use a little more support in your supply chain, Coyote can help.

And we can do a lot more than just full truckload brokerage (though we’re industry leaders at that too).

80% of your peers value supply chain providers that can perform multiple functions — in addition to multimodal carrier procurement, you can access a full suite of specialized logistics services with Coyote.

Whether you need…

- Help running your next transportation RFP

- Executing a special project with dedicated capacity and drop trailers

- Outsourcing an entire transportation management team

…Coyote has something to offer.

You can even use our free, cloud-based TMS (really, it’s free).

Learn why Coyote is a great addition to any shipper’s outsourced provider network.

Talk To a Logistics Specialist

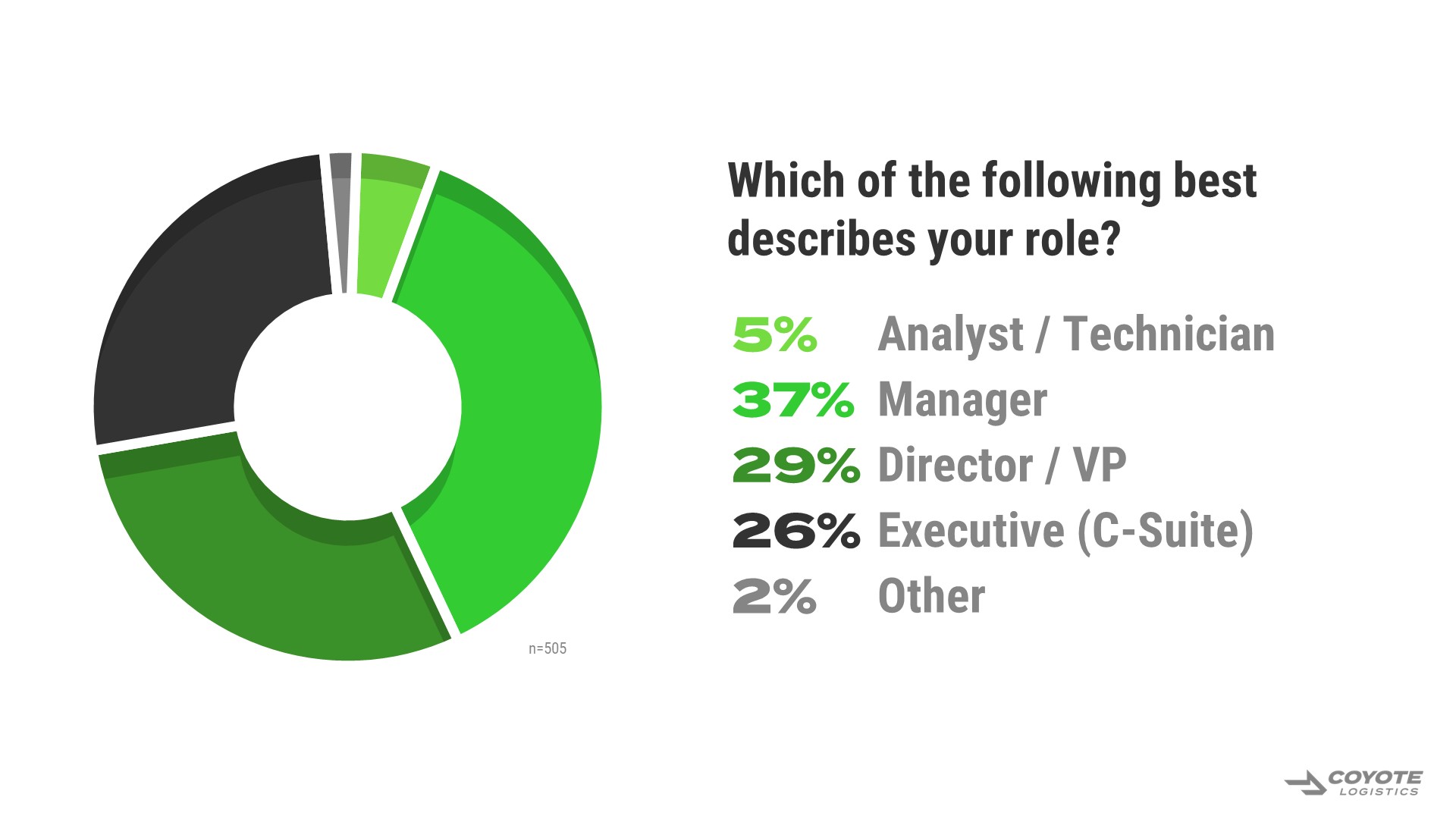

Respondent Demographics & Methodology

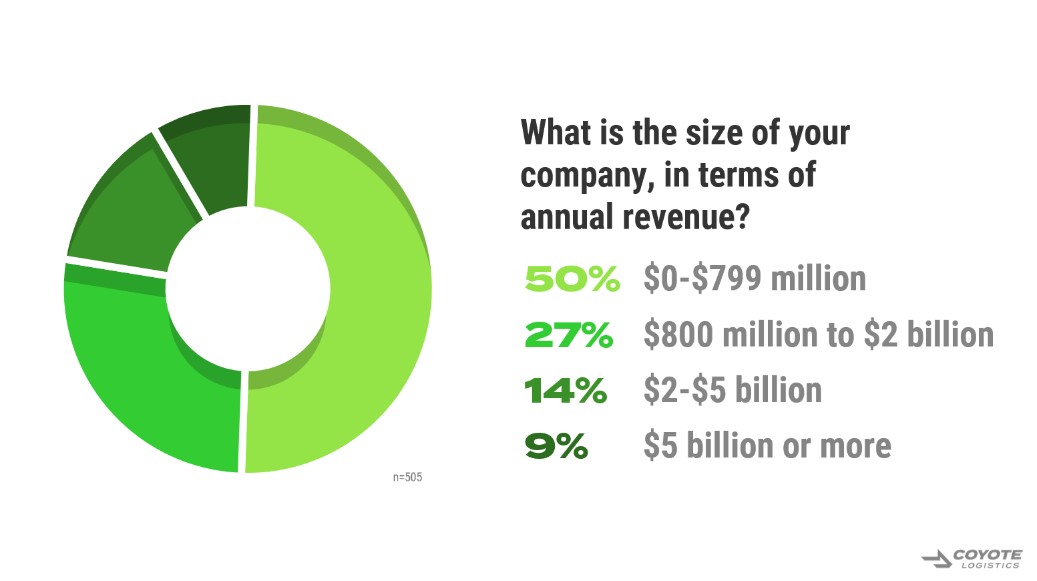

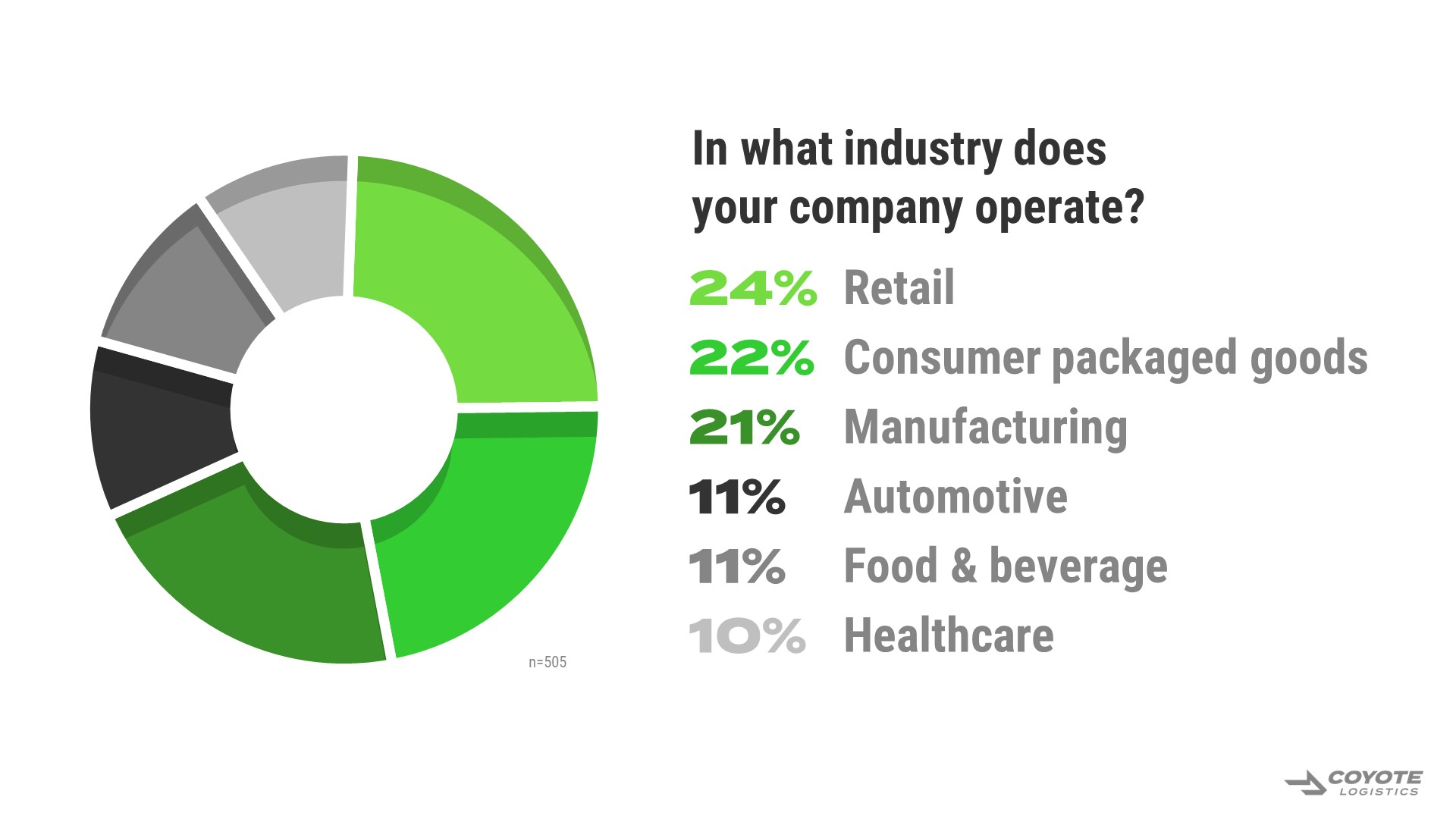

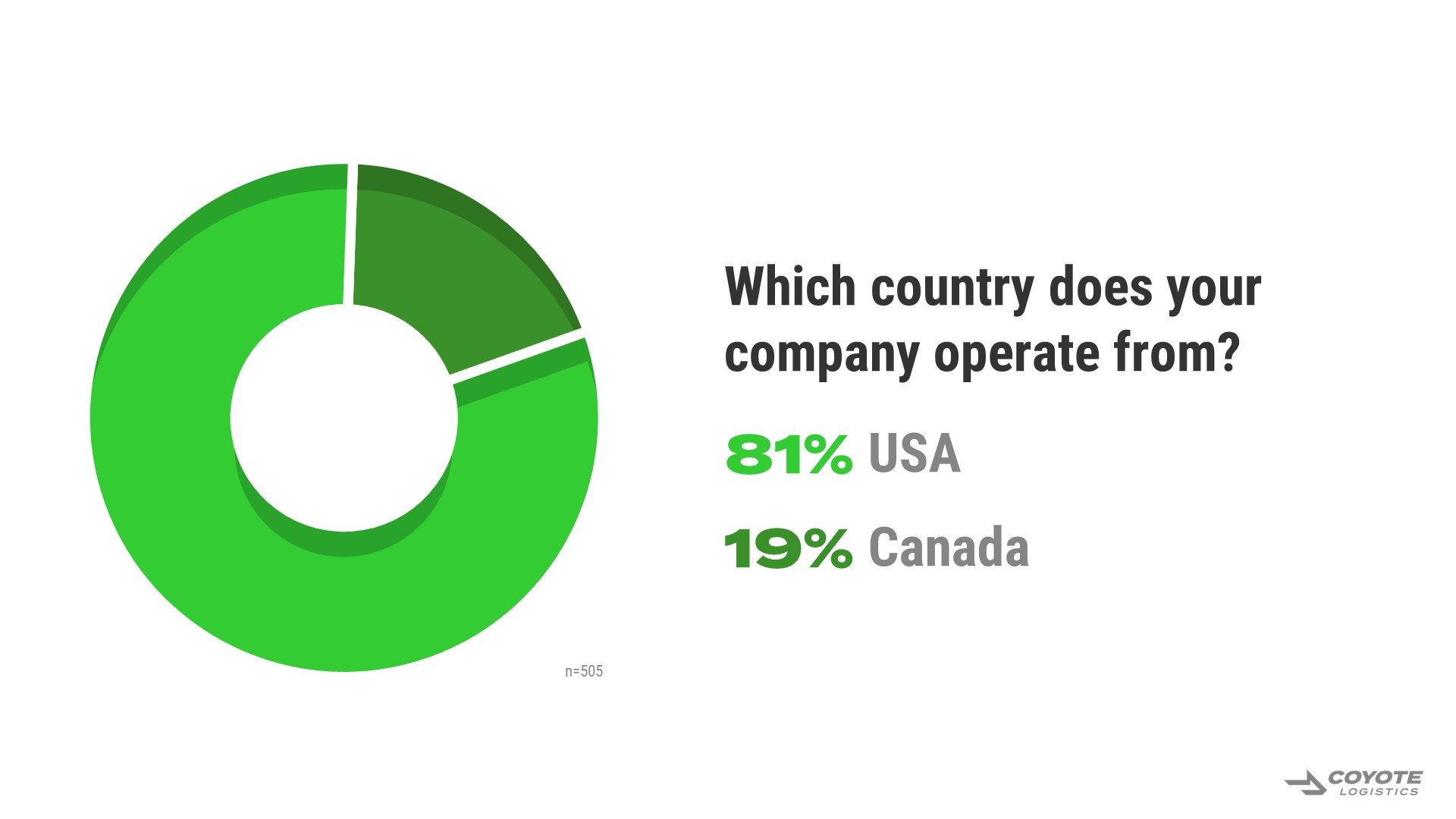

To get actionable insights on how shippers approach outsourcing, we asked over 500 logistics professionals from businesses in a range of sizes and industries.

Methodology

We worked with CheckMarket — an independent, third-party research firm — to source and survey relevant contacts for this study.

All respondents were anonymous, and self-identified as having influence or sole decision-making authority over their supply chain vendors and providers.

Surveys were completed from November 2022 to January 2023.

Supply Chain Outsourcing Definition

We provided all respondents with the following definition to keep in mind when answering the questions.

We’re going to ask you a series of questions about supply chain outsourcing.

In this context, think of “outsourcing” as anytime you use an external provider (AKA a third party) for a supply chain task.

This should include basic applications (e.g., using a freight broker to source a carrier on a single shipment) as well as comprehensive solutions (e.g., a fully outsourced warehouse provider).