Intermodal vs. Truckload: 4 Things Every Shipper Should Know

Intermodal shipping adds capacity, cuts transportation costs and can reduce your emissions by up to 30% compared to over-the-road shipping.

It’s an excellent full truckload conversion product that can be a key component of flexible shipping strategies designed to navigate tight truckload markets.

But while intermodal transportation is a reliable, safe, eco-friendly and cost-effective service, it’s important to understand the nuances of moving freight on the rails to help you plan for success.

Let’s dive into four key differences between intermodal and truckload shipping while you consider how to incorporate both modes into your supply chain.

Intermodal freight is an efficient full truckload conversion product, but there are 4 key differences between the 2 modes that shippers should understand.

1. When Your Shipment Is on the Train, It’s on the Train

When you ship freight full truckload, you have a comparatively high degree of control over the product.

Need a re-route? Have your provider call the carrier. Truck breakdown? It’s relatively easy to source another one. Besides equipment failure, most delays are usually limited to minor traffic jams.

With intermodal, one train is moving hundreds of loads on a fixed track. Trains are arriving to and departing from intermodal facilities with thousands of loads.

Railroads do not prioritize individual containers. If there is congestion or track repairs, re-routing a mile-long train is not as simple as taking a different highway.

No intermodal provider, whether asset-based or broker, can solve rail delays.

The key is to work with a provider who uses experience and technology to plan ahead, and who prioritizes communication and service once your freight is in transit.

2. Intermodal Transit Takes More Planning Than Truckload

Intermodal shipping is not by any means slow, but shipments can take longer from beginning to end than truckload freight.

If you have time-sensitive deliveries, you and your intermodal provider must understand in detail how your freight will move on the rail — this is why a service-oriented provider is so important.

The right provider can help you nail down all the important details, from whether your freight is eligible for a 40′ container or a standard 53′ to quantitative ways intermodal shipping can help you hit your sustainability goals.

But even though your provider will be the experts, having a basic understanding of rail transit yourself will help you plan for success.

Related: To learn about planning your intermodal shipments, read the Intermodal Beginner’s Guide.

Here’s How Intermodal Train Schedules Work

Intermodal trains run on predetermined transit schedules. Some lanes in high-traffic corridors run multiple trains per day, while other lanes only have a couple trains per week.

Every train has a “gate-cut” time — if you want your container to be on that outbound train, the driver needs to check-in at the intermodal facility’s gate before the cutoff time.

If the driver arrives after the cutoff, the container will head out on the next scheduled train.

Think of intermodal schedules like going to the airport.

If you have a 5 p.m. flight, the plane will take off at 5 p.m.

It won’t leave at 3 p.m. if you’re sitting at the gate two hours early, and it won’t wait for you if you show up late.

All intermodal schedules are publicly available on the railroads’ websites, but again, your intermodal provider should be the one interpreting these and planning for you.

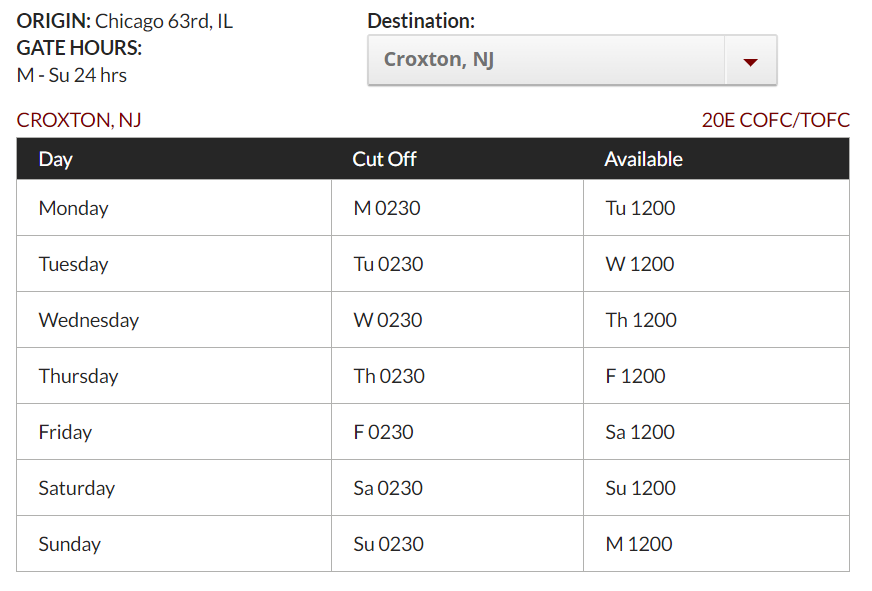

Here’s an example of one of the Norfolk Southern’s Chicago to New Jersey schedules.

The column marked “Cut Off” indicates the time your container must be in the gate at the origin railyard to be loaded onto that day’s train. The column marked “Available” displays the time your container will be ready for pickup at the destination railyard.

Intermodal Gives You Shipment Visibility in Transit

Once the train is in transit, the railroads provide automated tracking updates at frequent checkpoints.

Though you may not be able to do anything to affect transit, intermodal provides great visibility into your shipments.

Coyote has direct digital connectivity with all Class I railroads, and we get a constant stream of shipment updates to our centralized freight platform. You can access those updates at tracking.coyote.com, or we can feed them into your system via API or EDI.

Your Freight May Interchange Between Two Railroads

There are two primary railroads in the western half of the U.S. (the Union Pacific and BNSF) and two primary railroads in the eastern half (the Norfolk Southern and the CSX). They are constantly working together, handing off shipments to each other.

If you’re shipping across the country, your shipment is probably going to ride on two railroads.

This is called an interchange.

You do not need to do anything for the interchange to happen — it is a seamless process that the railroads handle themselves.

All you need to know is that when they occur, it can add time to your door-to-door transit.

Generally speaking, if your intermodal shipment is crossing over the Mississippi river, it will probably interchange from one railroad to the other.

This graphic is not comprehensive, but it illustrates the two primary western and eastern U.S. railroads and their approximate service areas.

What Happens When Your Intermodal Shipment Arrives at the Destination Rail Terminal

As you can see in the rail schedule above, the rails offer an “available” time, an estimated time when your container will be pulled off the train, placed on a chassis, and ready for delivery.

Your intermodal provider will receive a notification, and coordinate for a driver to pick it up and deliver at the destination facility.

Working with an Experienced Provider Makes Transit Planning Easier

A good intermodal service provider will take the guesswork out of planning for intermodal transit — it should be as simple as your full truckload experience.

Though the railroads publish schedules, they aren’t always 100% accurate and they don’t guarantee transit.

Experienced provides can leverage their historic transit data and technology to create predictive analytics that offer a clearer picture of actual door-to-door rail transits.

If your provider isn’t helping you create shipment and appointment scheduling plans that meet your business’s needs, it’s time to look elsewhere.

3. Blocking & Bracing Is Your Responsibility When You Ship Intermodal

In full truckload shipping, the driver is responsible for making sure the product is correctly blocked and braced before leaving the shipper’s facility.

That driver will be held accountable for product integrity from the shipper until the trailer bumps the dock at destination.

In intermodal shipping, since the sealed container will change hands between at least three different carriers, the shipper is responsible for correctly blocking and bracing the product at its origin.

Though intermodal transit is smooth, containers experience continuous, gentle vibrations while riding on the tracks — over the span of hundreds of miles, product and pallets can shift.

Proper blocking and bracing are important for every mode, but they are especially important when shipping intermodal.

Improperly loaded pallets can cause several issues, all of which have accessorial fees associated with them.

- Damaged and refused product

- Product restacking

- Pallet(s) sliding, causing overweight trailer axles at destination

- Leaning containers

How Shippers Block and Brace Shipments for Intermodal

Specific loading plans and patterns will vary based on commodity and packaging. Generally speaking, most methods seek to reduce empty space with void fillers (such as air bags or honeycomb cardboard fillers).

If you are unsure how to properly load your product, the American Association of Railroads publishes a detailed intermodal loading guide that offers great technical information and diagrams for a wide variety of commodities.

The railroads have a vested interest in helping you ship intermodal. If you need additional help, they have damage prevention specialists dedicated to helping shippers design loading plans and diagrams for intermodal shipping.

We can connect you to the necessary resources to prepare your freight for intermodal conversion.

4. Accessorials Are More Common in Intermodal Than in Truckload Shipping

Compared to full truckload accessorials, intermodal shipping has a few different ones, and they are generally more common.

But there’s nothing to be afraid of — most intermodal loads do not incur any accessorials, and proper planning and best-practices by your team can make them even less common.

When accessorials occur, it’s important to keep in mind the total cost-savings that intermodal brings to your supply chain.

When getting intermodal rates, make sure you understand how your provider approaches accessorials in their pricing, and that they give you a candid and realistic overview of their accessorial schedule.

Why Accessorials Can Be More Common in Intermodal

Intermodal carriers, both rail and drayage, rely on efficiency to provide cost-savings.

Railroads:

Multiple daily trains bring hundreds of containers into an intermodal ramp, adding to the hundreds already on site. To provide reliable service, intermodal ramps need to keep their equipment — containers, chassis and trains — turning over quickly.

To incentivize maximum operational efficiency from shippers and carriers, railroads use storage fees to get newly arrived, loaded containers out for delivery as soon as possible.

Drayage Carriers:

Most drayage drivers make multiple pick-ups and deliveries per day and are on a very tight schedule. Therefore, they are more likely to charge for anything that causes a delay.

Let’s Review: 4 Things You Need to Know to Convert Truckload Freight to Intermodal

Intermodal is a full truckload conversion product with many benefits including added capacity and reduced cost, but there are a few core differences every shipper should understand.

- When your product is on the train, it’s on the train.

- Transit can take more planning.

- Blocking and bracing are the shipper’s responsibility.

- Accessorials can be more common.

Implementing new strategies to your supply chain is never easy, but working with an experienced, customer-centric intermodal provider can make the process simple.

Understand the Differences Between Intermodal & Truckload? Now Become a Pricing Expert

With intermodal, there are two drayage carriers, a railroad and, depending on how you ship, an intermodal marketing company (IMC).

It’s a more complex process than truckload, and with that, comes more complex pricing structures.

Learn how they work to get the best rate for your shipment with this guide to intermodal pricing.