Shipper

5 min read

Navigating Tariff Uncertainty & Trade Policy Shifts

The global trade landscape faces ongoing volatility, with the potential for significant shifts in trade policies and tariff structures.

3 min read

Navigating the Seas of Global Trade: Choosing a Reliable Provider for Ocean Freight Shipping

Get five tips for choosing a reliable provider for your ocean freight. Work with an NVOCC who understands customs and cares about optimizing your operations.

3 min read

Pool Point Shipping: Streamlining Your Retail Supply Chain

Pool point shipping, also known as pool distribution, is a strategic approach to freight management that consolidates multiple shipments destined for the same geographic region.

6 min read

Balancing Freight Cost & Service: 7 Ways to Get More Value With Your Transportation Spend

Working with an experienced, multi-modal logistics provider can help shippers control their freight costs and achieve long-term savings.

7 min read

Route This Way: 5 Tips for Getting the Most Out of Freight Routing Guides

Is your supply chain ready for a freight routing guide? How to make one and how to use technology to get the most out of it. Read 5 freight tendering tips.

3 min read

Dedicated Transportation Services: Optimizing Your Supply Chain for Success

Are you searching for dedicated transportation services that deliver more than just timely deliveries? In today’s competitive landscape, optimizing your supply chain is crucial for profitability and growth.

8 min read

How to Prepare for a Tight Capacity Market: 4 Steps Shippers Can Take

When spot rates rise and truckload capacity gets tighter, follow these 4 tips. Keep your freight moving in a tight capacity market.

10 min read

Shipper of Choice Do’s and Don’ts: 9 Best Practices to Improve Carrier Relationships

When freight market conditions get tighter, you'll want to stand out with carriers. Learn how to become a shipper of choice.

9 min read

What to Expect When You’re Expediting: 4 Expedited Truckload Shipping Tips

Learn what your options are for expedited truckload freight. Read 4 tips for ensuring a smooth expedited shipping experience.

13 min read

AB5 & the Trucking Industry: How This California Bill Could Impact Driver Capacity

Get an easy-to-digest overview of the California AB5, what it could mean for the trucking industry, & how drivers, owner-operators & carriers could be impacted.

6 min read

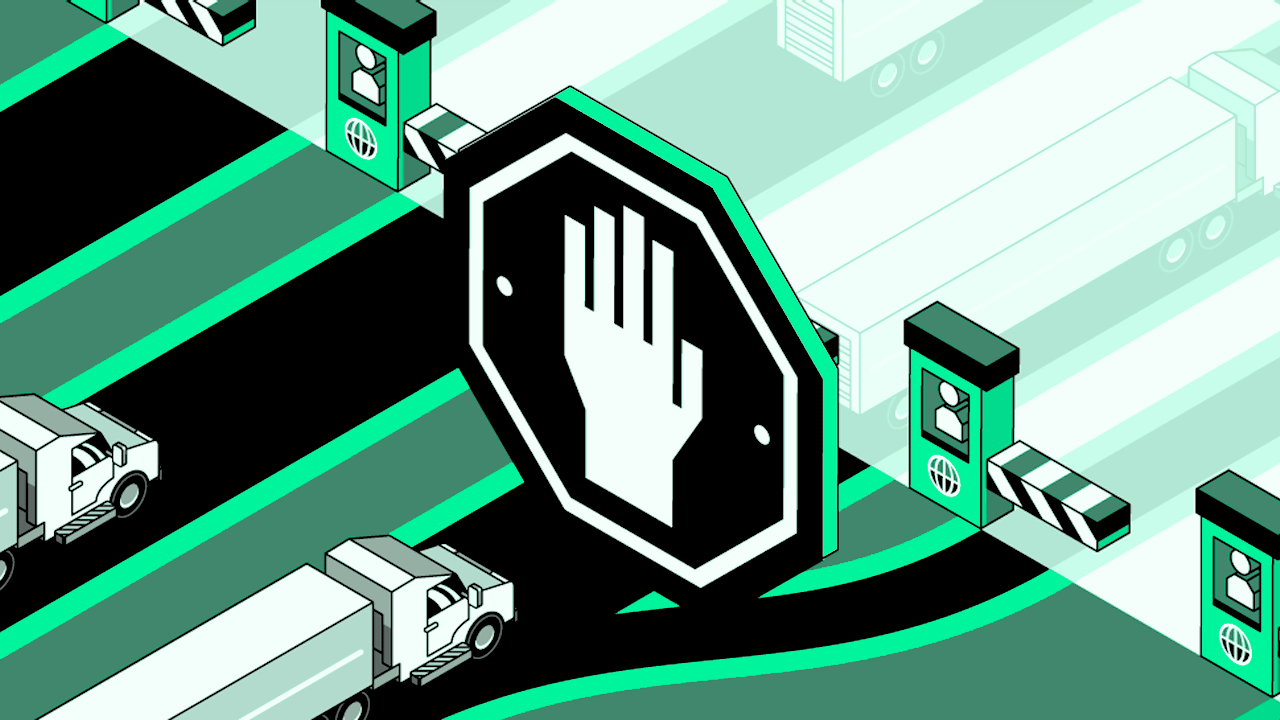

Avoid the 5 Risks of Cross-Border Mexico Freight Shipping (From Cargo Theft to Lengthy Delays)

Learn how to protect your shipments between Mexico & the U.S., from cargo theft to insurance, with these cross-border shipping best practices.

10 min read

Mexico Cross-Border Guide: How to Ship Truckload Freight Over the Southern Border

From paperwork to transloading, this step-by-step guide gives you everything you need to import & export cross-border Mexico truckload freight.

5 min read

Canadian Truckload Market: 8 Things Every Cross-Border Shipper Should Know

The U.S. and Canadian truckload markets are similar, but there are several key differences. Learn what they are & how to navigate the market with confidence.

6 min read

Canada vs. Mexico Cross-Border: 5 Differences Shippers Need to Know

While freight shipping is similar across North America, there are a few key differences between the Canada and Mexico cross-border truckload markets.

9 min read

Canada Cross-Border Guide: How to Ship Truckload Freight Over the Northern Border

From BOLs & customs invoices to importing & exporting, this step-by-step guide gives you everything you need to ship cross-border Canada truckload freight.

5 min read

What is Volume LTL? When & How to Use This Mode in Your Supply Chain

Have a larger shipment that's still too small for a full truckload? Volume LTL and partial truckload are great alternatives. Learn how and when to use them.

9 min read

Spot vs. Contract Rates: What’s the Difference in Truckload Freight Shipping?

Learn the differences between contract rates and spot rates in truckload freight shipping. Find out when shippers should look for contract rates.

8 min read

How to Handle 5 Common LTL Shipping Challenges (3PLs Can Help)

Learn about 5 LTL shipping challenges that most businesses face. Find out how experienced shippers avoid them (and how 3PLs can help).

5 min read

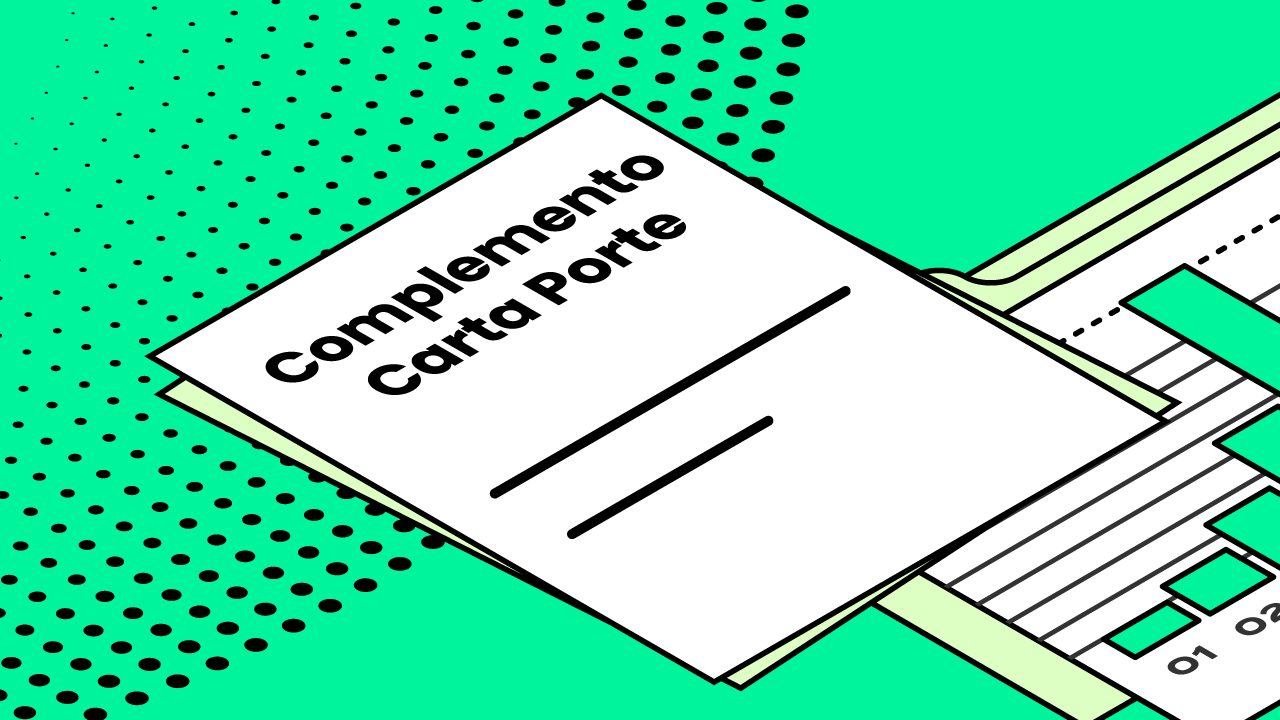

Complemento Carta Porte Explained: FAQ for Essential Mexico Freight Shipping Documents

Get answers to frequently asked questions about the Complemento Carta Porte, a new document required to improve security for freight shipped in Mexico.

7 min read

Build for Any Market Conditions: Tips for Creating a Resilient Supply Chain

Learn what resilient supply chains look like and how to strengthen yours. Ship confidently in any freight market conditions with these tips.

8 min read

The Small Business Guide to Logistics Technology: 5-Steps for Growing Shippers

Learn how small businesses choose and utilize logistics technologies. Follow our 5-step guide to find the right supply chain technology solution for you.

7 min read

Customs Broker Basics: What Cross-Border Shippers Need to Know

If you're shipping cross-border with Canada or Mexico, learn the basics of customs brokerage and how to and why you should work with a broker.

4 min read

The 5 Biggest Cross-Border Shipping Mistakes (Avoid These)

Importing and exporting freight to Canada and Mexico can be tricky. These cross-border shipping mistakes will cost you time and money. Learn to avoid them.

8 min read

CSP vs. Blanket Rates: How to Find the Right LTL Pricing for Your Freight

Learn the difference between customer-specific pricing and blanket rates for LTL shipping, and find out when CSP makes sense for your freight.

13 min read

The ABCs of LTL Accessorials: When, What & How to Avoid

Learn why accessorial fees are more common in LTL shipping, what some of the most frequent accessorials are and how to avoid them.

10 min read

The Art & Science of Supply Chain KPIs: Measuring Logistics Success

Get insights from original research on how to set, manage & use logistics KPIs in your supply chain strategy.

8 min read

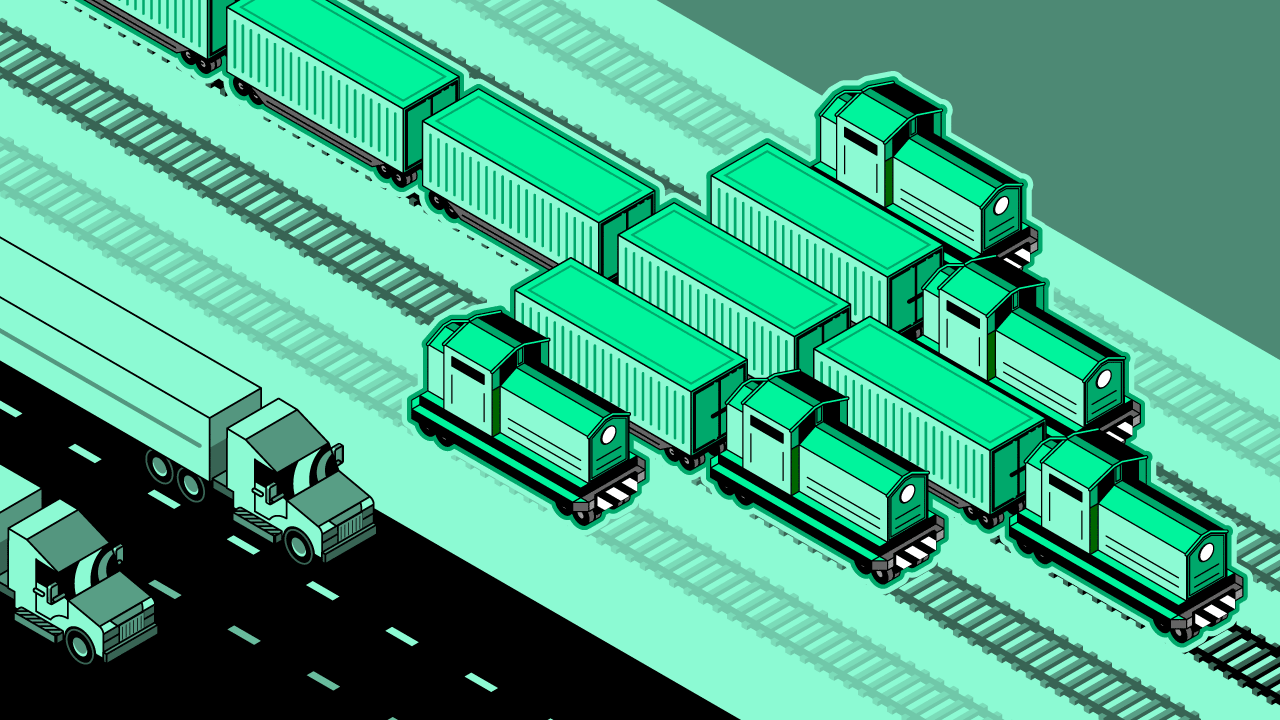

Intermodal vs. Truckload: 4 Things Every Shipper Should Know

Know the four main differences between shipping freight intermodal vs. truckload and keep them in mind when you choose the right mode for you.

9 min read

Is Intermodal More Sustainable? Strategies and Resources for Improving Efficiency on the Rails

Learn how intermodal shipping can (and can't) improve your supply chain sustainability. Get connected to government and nonprofit sustainability resources.

9 min read

3 Types of Intermodal Pricing Every Shipper Should Know

Discover the different types of intermodal pricing, find out what goes into each rate and learn how a 3PL can help your intermodal business strategy.

10 min read

What Is Intermodal Shipping? A Beginner’s Guide to Moving Freight on the Rail

Learn the 3 parts of an intermodal shipment, the key benefits of moving intermodal freight and a comprehensive glossary of terms to know.

7 min read

A Tale of Two Markets: 53’ Domestic vs. 40’ International Intermodal Containers

Learn the differences between domestic and international intermodal containers. Find out how to access 20', 40', 45' and 53' containers for your freight.

8 min read

Crunch the Numbers: How to Get the Most Out of Your Supply Chain Data

Learn what kinds of data you can collect from your supply chain, how you can track and visualize it with technology, and how to make it actionable.

9 min read

Get the Perfect LTL Freight Quote: 6 Steps to Better Rates for Your Shipments

Want to get accurate LTL freight quotes for your shipments? Use these 6 best practices to get the best LTL freight rates every time.

8 min read

Why You Should Outsource Your Next Transportation RFP (& 4 Benefits You Can Expect)

Learn when to outsource transportation RFP management, how working with a 3PL can improve your supply chain procurement and how to sell it to your team.

7 min read

How to Get the Perfect Truckload Spot Rate: 8 Rules for Freight Quoting

Every shipper has to get spot quotes for their truckload freight. These do's and don'ts will help you get the best spot rate every time.

8 min read

So Long Spreadsheets! How to Choose a TMS That Eliminates Manual Shipping Processes

Learn what to look for in a freight platform, key transportation management system (TMS) features, and how to make the right choice for your shipping network.

7 min read

LTL vs. Full Truckload: 7 Key Differences that Every Shipper Should Know

Full truckload and less-than-truckload are similar modes of freight shipping, but all shippers should understand these 7 key differences between them.

7 min read

How Transportation Policy Impacts the Supply Chain: 4 Important Facts for Shippers & Carriers

Learn how U.S. government transportation policy impacts the supply chain. Know the difference between regulations & laws, plus how policy advocacy works.

6 min read

Freight Security 101: 5 Shipper Tips for Avoiding Cargo Theft

With cargo theft on the rise across supply chains, learn how you can bolster your freight security. Choosing the right broker & communicating openly can help.

7 min read

4 Benefits of Freight API Integration (& 3 Tips for Getting the Most Out of It)

Learn how and why to connect to your logistics provider's freight API. Find out signs it's time to integrate, how to get started and benefits you'll enjoy.

7 min read

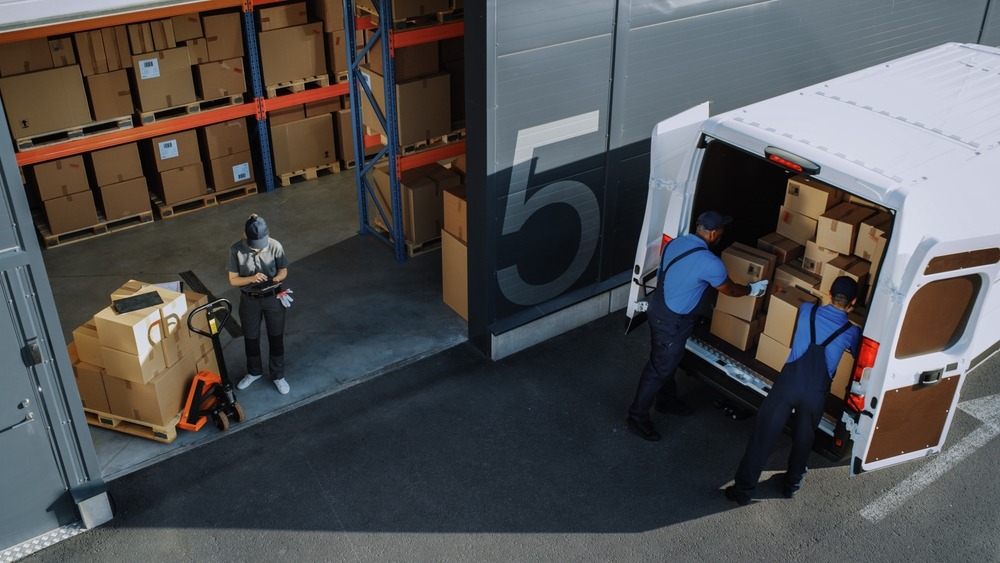

Set a Last Mile Logistics Strategy That Delivers With This 4-Step Guide

Use this 4-step guide to improve your last mile logistics strategy. Learn about delivery options, service requirements, providers and how a 3PL can really help.

9 min read

Your Step-By-Step Project Freight Guide (Use This Checklist)

Learn about common shipping project scenarios, how to find capacity and how a 3PL can help. Use our checklist for the next time you have project freight.

6 min read

Stay Fresh: A Guide to Produce Season Shipping in the Truckload Market

Learn how produce shipping season impacts the truckload market regionally and nationally across the U.S. Prepare your supply chain for seasonal surges.

9 min read

What Is Private Fleet Trucking? How Shippers Use Private & Dedicated Fleets

Learn the difference between private fleets and dedicated fleets, why shippers use each, and how 3PLs can help.

9 min read

Never Run Empty: How to Start a Private Fleet Backhaul Program (and Why a 3PL Should Help)

Learn benefits of starting a backhaul program for your private fleet, how to find freight, details to keep in mind when getting started & how a 3PL can help.

8 min read

5 Tips for Choosing a Cross-Border Mexico Freight Provider: Service, CTPAT Security & More

Learn how to balance cost, service and security when choosing your cross-border carriers, including insight on CTPAT, procurement and operations.

9 min read

How to Ship Oversized Loads: Weigh Your Options for Heavy Haul Freight

Learn what freight qualifies as an oversized load, what permits and open deck equipment you need to move it, and how a 3PL can help.

9 min read

Build vs. Buy: Why, When & How to Outsource Your Supply Chain Operations

Learn the benefits of outsourcing some or all of your supply chain, when it's time to buy vs. build, and what functions are commonly outsourced.

8 min read

What is Outsourced Logistics? The Basics of the 3PL Market

What shippers need to know about outsourced logistics basics and the 3PL market, with insight from a logistics expert.

10 min read

Guide to Open Deck Trailers: Shipping With Flatbeds, Step Decks, Goosenecks & More

Learn about the flatbed carrier market, how to quote & ship open deck trailers, and equipment types including RGN, double-drop, step deck & more.

7 min read

Get Connected: 5 Reasons API Integration With Carriers Is Great for LTL Shippers

Find out how API & EDI integration can benefit LTL shippers. Learn 5 benefits you can see if you connect digitally with a carrier or 3PL.

11 min read

Crushing It: Handle LTL Freight Claims Like a Pro With These 8 Lessons

Learn why freight claims are more common in LTL shipping, what you can do to avoid them, how to handle them when they arise and how a 3PL can help.

10 min read

LTL Freight Class vs. NMFC Codes: What’s the Difference?

Find out how to determine freight density, LTL freight class, and NMFC codes when shipping LTL freight.

9 min read

Take a Load Off: 7 Reasons to Work With an LTL Freight Broker

Learn 7 reasons why an LTL freight broker's technology, expertise and carrier relationships can save you time, money and headaches.

10 min read

Building an LTL Carrier Network? Set Your Procurement Strategy With These 9 Tips

Learn what questions to ask LTL carriers during your next procurement event, tips for running a successful bid and how to manage your LTL carrier network.

6 min read

When to Trust the Experts: 4 Signs You Should Outsource Logistics KPIs

Learn how to recognize when your business might benefit from outsourced logistics and find out how outsourcing can improve your service and performance.

6 min read

Taking a Both/And Approach to Supply Chain Outsourcing

Learn why shippers prefer a mix of outsourced and in-house supply chain functions. Find out how to determine which functions to outsource to add the most value.

9 min read

How to Start a Continuous Improvement Program: 6 Simple Steps for Your Supply Chain

Learn how to cut costs, improve service and boost employee engagement by setting up a continuous improvement program in your supply chain.

7 min read

Supply Chain Network Optimization Explained: Tuning Up Your Transportation & More

Learn what supply chain network optimization actually means, what you can optimize, how consultants can help and tips for taking a data-driven approach.

8 min read

What Is Power Only Trucking? (& How 3PLs Combine it With Leased Trailers)

By separating the power unit (driver & truck) from the trailer, 3PLs create flexible shipping solutions using large networks and digital freight matching.

8 min read

Get to Know Your Drayage Carriers: How Containers Move to Ports & Intermodal Ramps

Find out what drayage carriers do to keep intermodal freight moving. Learn about the drayage market and how to get great service.

6 min read

What is a TMS? A Beginner’s Guide to Transportation Management Systems

Learn the key functions of a transportation management system or TMS, how it is different than a WMS, and how long it takes to implement.

6 min read

The Truth About Digital Freight Matching: 4 Things You Need in a DFM Provider

Learn the difference between traditional brokers and newer digital matchers (DFM), and how to choose the right provider for you.

9 min read

What Is a 3PL? The Beginner’s Guide to Third-Party Logistics

Everything you need to know about third-party logistics providers, including asset-based vs. non-asset-based, the basics of brokerage and when to use a 3PL.

10 min read

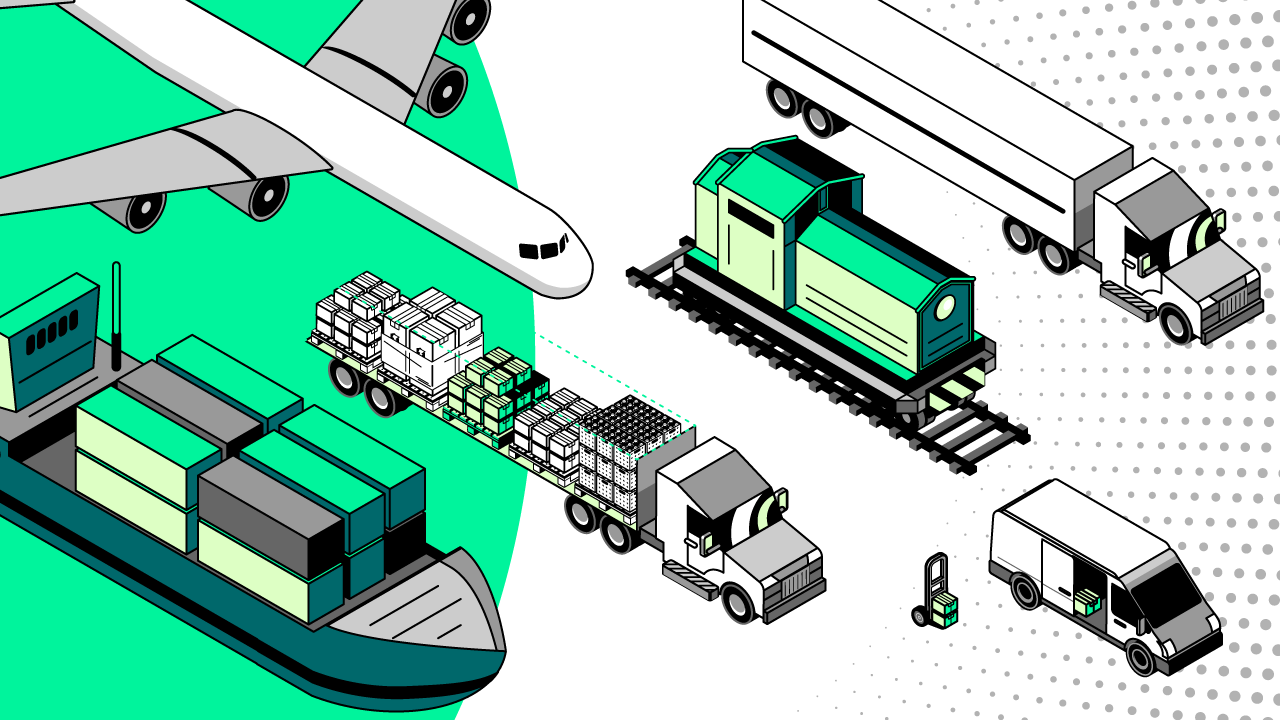

Know Your Modes: The 7 Ways to Ship Freight

Learn when to use full truckload, LTL, shared truckload, intermodal, box truck or sprinter van. Find out which shipping method is right for your freight.

6 min read

Transloading vs. Through-Trailer: How to Choose the Right Mexico Cross-Border Service for You

Learn the differences between transloading and through-trailer service at the U.S.-Mexico border and why transloading solutions are usually recommended.

8 min read

What Is Supply Chain Consulting? A Guide to Outsourcing Logistics Management Services

Learn all the ways supply chain consulting helps shippers improve their logistics performance and what to look for in a good supply chain consultant.

5 min read

Don’t Make These 3 Summer Shipping Mistakes: Take Temperature-Controlled Freight Seriously

Learn how poor temperature-controlled shipping strategy can lead to damaged or rejected freight. Avoid the 3 most common reefer shipping mistakes.

12 min read

Preparing for Your 2025 RFP? Here Are 7 Steps for a Better Transportation Bid

Follow these 7 steps to prepare for your next transportation network bid. Run a successful RFP and lock in service at a manageable rate.

5 min read

Shared Truckload Explained: When to Use It, How to Find It & Why It’s Worth the Effort

Learn how shared truckload shipping compares to full truckload and LTL, the benefits to using it, and how to get started with a 3PL.

12 min read

Reefer Trucking 101: Answers to 10 Essential Refrigerated Freight Questions

Learn the basics of refrigerated (reefer) trucking in this guide to shipping temperature-controlled freight. Read about reefer trailers & how to use them.

2 min read

API vs. EDI in Freight Management: What’s the Difference?

API and EDI integrations handle digital data transfers for supply chain professionals. Here are 4 reasons by APIs excel at quoting, tracking & load building.

14 min read

The 7 Different Types of LTL Carriers (& When to Use Each)

Learn the basics of the LTL market — including how to choose an LTL carrier and how working with a freight broker can benefit your business.

2 min read

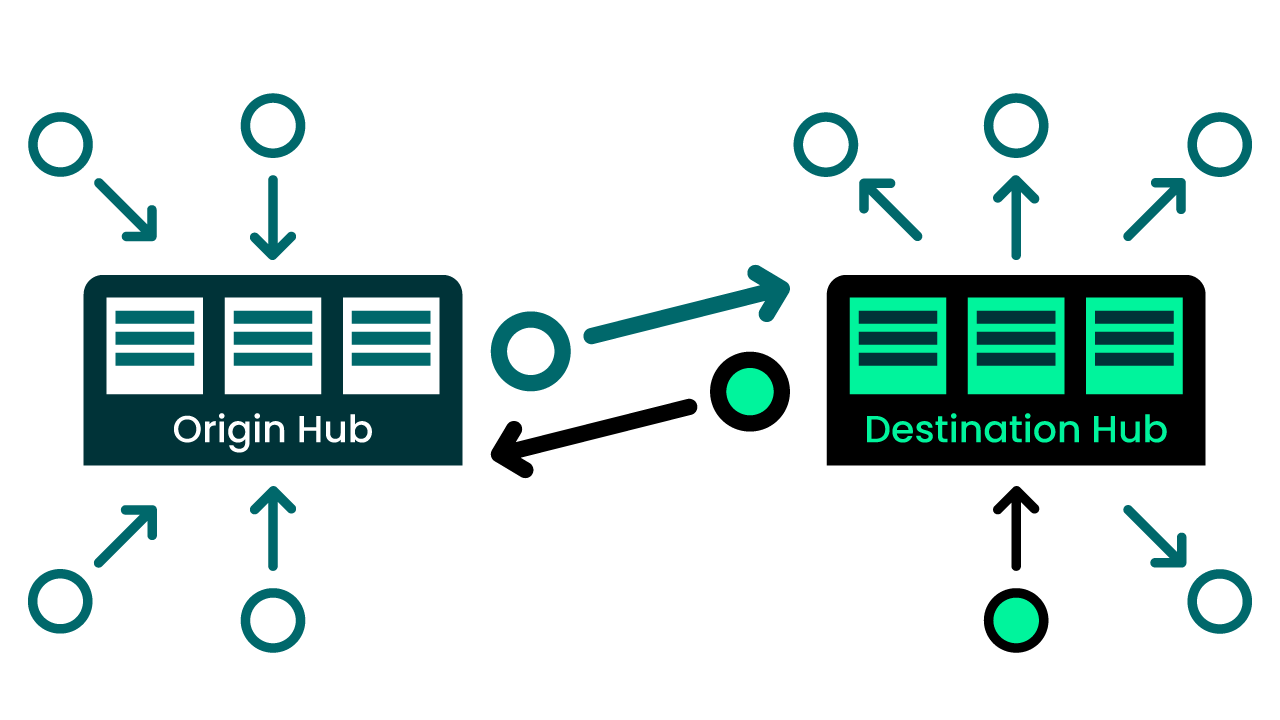

The Power of Transportation Control Towers

As a centralized hub, a control tower offers end-to-end visibility of the entire transportation network. It acts as the nerve center for logistics operations to monitor and manage the entire transportation network, ensuring each component works harmoniously.

3 min read

Honoring Service and Supporting Success: RXO’s Commitment to Veterans

As Veterans Day approaches, RXO reaffirms its unwavering dedication to the military community.

3 min read

Mastering Supply Chain Resilience: Mitigating Risks in an Unpredictable World

The global supply chain is anything but predictable. Natural disasters, political instability, cyber threats, and ever-changing regulations create a volatile landscape for businesses.

2 min read

Warehousing: The Future of On-Demand Space and Logistics

In today’s rapidly changing market, the soaring demand for efficient and flexible warehousing solutions is pushing companies to find innovative methods to streamline supply chains, cut costs and enhance service levels.

2 min read

Air Expedite: Critical Solutions for Fast Freight Movement

Air expedite services have become a fundamental component of today's logistics sector, providing the necessary speed and flexibility to meet industry demands. These services enhance supply chain agility and flexibility, making them essential in logistics.

3 min read

Navigating Oversized Loads: Key Considerations for Choosing a Heavy Haul Provider

Heavy haul services play a pivotal role in today’s logistics, providing essential support for transporting oversized and overweight cargo.

2 min read

The Future of Freight Brokerage: Responsible AI in the Era of GenAI

The freight brokerage industry is on the cusp of a major transformation, driven by the power of Artificial Intelligence (AI).

2 min read

Ground Expedite: The Unsung Hero of Modern Supply Chains

Learn how ground expedite services are transforming supply chains in industries like pharmaceuticals and automotive.

2 min read

Finding the Right Flatbed Truck Provider

When looking for a flatbed provider, shippers should prioritize providers with proven expertise, robust connectivity and ample capacity.

2 min read

Choosing the Right Temperature-Controlled Trucking Provider for Summer Shipping

As we find ourselves at the heart of summer, temperatures are hitting their peak across North America. This presents unique challenges for shippers of temperature-sensitive goods, making the selection of a reliable and experienced temperature-controlled trucking provider crucial.

3 min read

Driving Success: Choosing a Managed Transportation Provider

Efficient transportation management is crucial for companies striving to optimize their supply chains. Understanding the nuances of managed transportation (MT) can significantly impact an organization’s bottom line.

3 min read

Navigating the LTL Landscape: Key Considerations for Shippers

Navigating the LTL landscape can be tricky for shippers, especially for those new to the game. Choosing the right LTL carrier is crucial for ensuring reliable, efficient, and cost-effective transportation of your goods.

2 min read

Innovative Beer Transportation Solutions: Navigating the Logistics Landscape

Beer makers are no strangers to the meticulous craftsmanship that goes into creating the perfect brew. A supply chain partner plays a crucial role in safeguarding that integrity throughout their journey to market.

2 min read

Overcoming the Challenges of Finding Reliable LTL Carriers: Your Guide to Secure, Efficient LTL Shipping

Choosing the right LTL carrier is crucial for ensuring reliable, efficient, and cost-effective transportation of your goods. But with a plethora of options available, the process can feel overwhelming.

2 min read

Building Trust and Transparency with AI Explainability in Logistics: A Deeper Dive

At RXO, we've implemented AI explainability tools for our internal operators, providing them with granular insights into our pricing algorithms.

4 min read

Leveraging RXO’s LTL Carrier Network: A Comprehensive Guide to Tailored Solutions

Finding the perfect LTL carrier for your business can feel like searching for a needle in a haystack. But with RXO’s extensive LTL carrier network, you have a powerful tool at your fingertips to streamline this process.

2 min read

Be Ready for CVSA International Roadcheck May 14-16 2024: Tips for Drivers, Carriers, and Shippers

The Commercial Vehicle Safety Alliance (CVSA) International Roadcheck is just around the corner, taking place from May 14-16, 2024.

2 min read

How Transportation Providers Can Bolster Shippers' Disaster Preparedness

Disasters strike without warning, leaving chaos in their wake. For shippers, these events can disrupt supply chains, jeopardize cargo and impact business continuity.

5 min read

5 Reasons Pool Distribution is Right for Your Business

If you’ve heard of pool distribution but are unsure if it’s the right “fit” for your company, these insights can help.

3 min read

Navigating the World of Bulk Transport

When transporting large-scale bulk good, shippers must weigh many factors with looking for the right transportation provider.

3 min read

Take the Stress out of Vehicle Shipping

To ensure a seamless customer experience, consider these 4 key points when finding a shipping provider.

6 min read

Creating an Adaptable Managed Transportation Solution With a Major North American OEM

This managed transportation case study involves a multinational automotive manufacturing corporation as a client.

4 min read

4 Ways to Ensure That Your Nearshoring Operations Run Smoothly

They are some key ways that shippers can improve their nearshoring strategies for a successful cross border experience.

5 min read

Capabilities of 3PLs Versus 4PLs

When outsourcing your logistics operations, many are faced with the option of a 3PL verses a 4PL solution offering

2 min read

Stay ahead of your supply chain disruptions

Ensure your supply chain has minimal disruptions with flexible transportation options

22 min read

10 Steps to Success when Shipping Air Cargo

Air transport efficiency begins with precise shipment information

4 min read

What is 3PL Managed Transportation?

A one-stop-shop created by experts to fit your business needs.

4 min read

4 Principles for a Lean Transportation Network

Lean companies create processes for operations that generate zero waste

4 min read

Benefits of a Transportation Control Tower

Effectively minimize delays and maximize impact of performance data

4 min read

Last Mile Logistics for Heavy Goods

The “final mile” — is the last leg of the shipping journey for a product

3 min read

Why a Regional Supply Chain Strategy Can Save You Time and Money

Regional strategies can unlock significant-cost savings, improved efficiencies

4 min read

Why Forward Stocking is Smart Inventory Management

A critical strategy for any business managing stock-levels close to customers

5 min read

5 Things to Look for in a Freight Forwarder

Determine your needs before selecting a partner based on experience and scope

5 min read

What is Air Charter Service?

The fastest possible option when something must reach its destination quickly

4 min read

Save Money Using Expedited Shipping Services

Why having a trusted Expedite partner to manage demand is critical